Recyclable and repairable thermosetting resin, preparation method and application thereof

A cyclic recycling, thermosetting technology, applied in the direction of adhesive types, coatings, adhesives, etc., can solve the problems of harsh recycling conditions, limited promotion and use, and expensive catalysts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

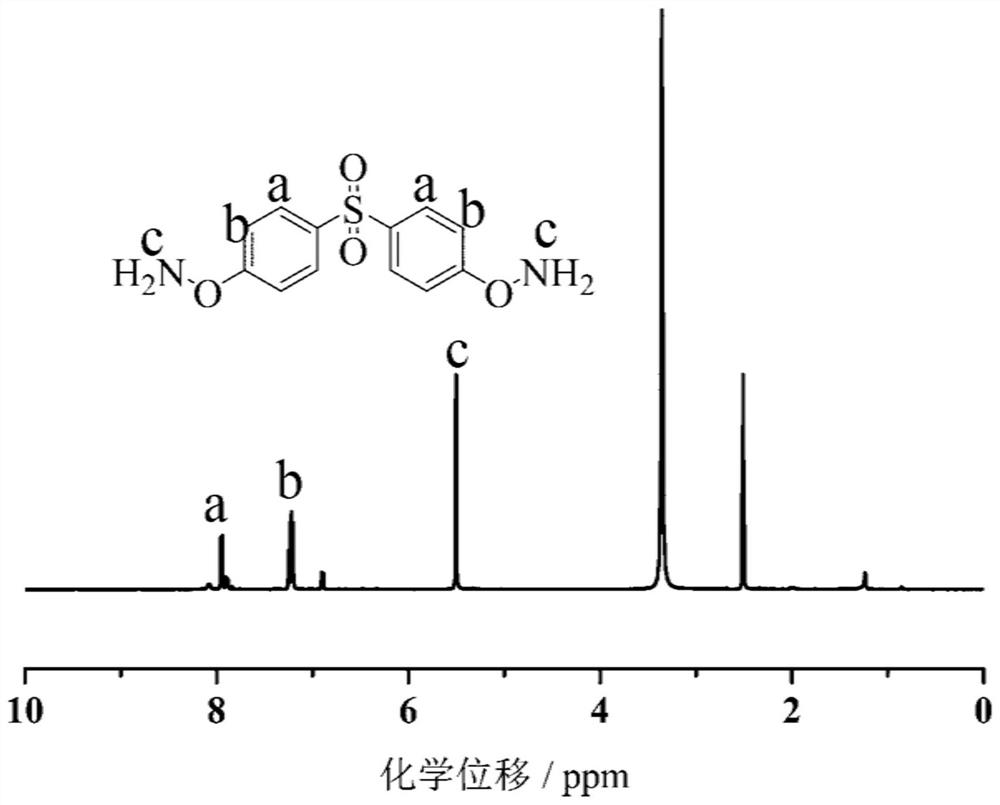

[0039] 1 part of 4,4-dihydroxydiphenyl sulfone, 3 parts of triphenylphosphine, 2 parts of N-hydroxyphthalimide, 5 parts of diisopropyl azodicarboxylate and 100 parts of dimethyl Sulfone, in N 2 Under protection, after stirring at -60°C for 24 hours, add 6 parts of hydrazine hydrate to react at -20°C for 48 hours, recrystallize in dichloromethane, filter and dry to obtain Hydroxyamino monomer 1 .

Embodiment 2

[0041] 2 parts of 2,2-bis(4-hydroxyphenyl)propane (bisphenol A), 5 parts of triphenylphosphine, 6 parts of N-hydroxyphthalimide, 10 parts of diisoazodicarboxylate Propyl ester and 50 parts of tetrahydrofuran were added into the three-necked flask, and in N 2 Under protection, after stirring at -50°C for 12 hours, add 8 parts of hydrazine hydrate to react at -10°C for 48 hours, recrystallize in dichloromethane, suction filter and dry to obtain Hydroxyamino monomer 2 .

Embodiment 3

[0043] 5 parts of 4,4'-(hexafluoroisopropylidene) diphenol (bisphenol F), 7 parts of triphenylphosphine, 10 parts of N-hydroxyphthalimide, 10 parts of azodicarboxylic acid Diisopropyl ester and 50 parts of tetrahydrofuran are added in the there-necked flask, and 2 Under protection, after stirring at -50°C for 18 hours, add 12 parts of hydrazine hydrate to react at -10°C for 48 hours, recrystallize in dichloromethane, filter and dry to obtain Hydroxyamino mono Body 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com