Digital intelligent oxygen generation system and control method

An oxygen generation system and intelligent technology, applied in the field of oxygen generators, can solve problems such as insufficient stability of oxygen production flow and concentration, greater influence of oxygen generation system, non-renewable damage of molecular sieves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

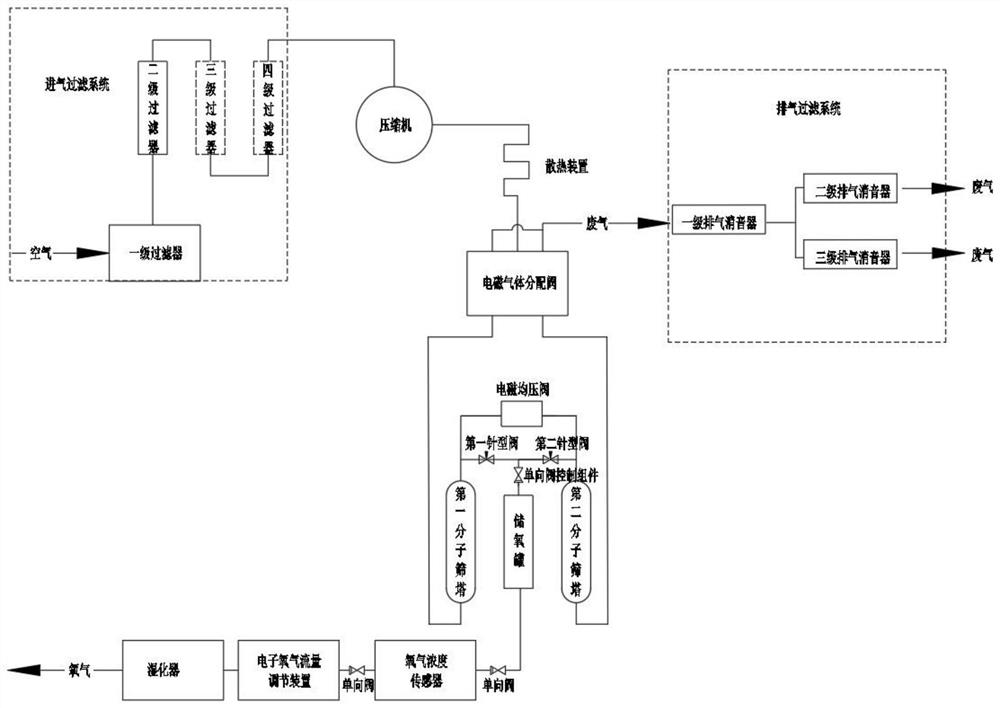

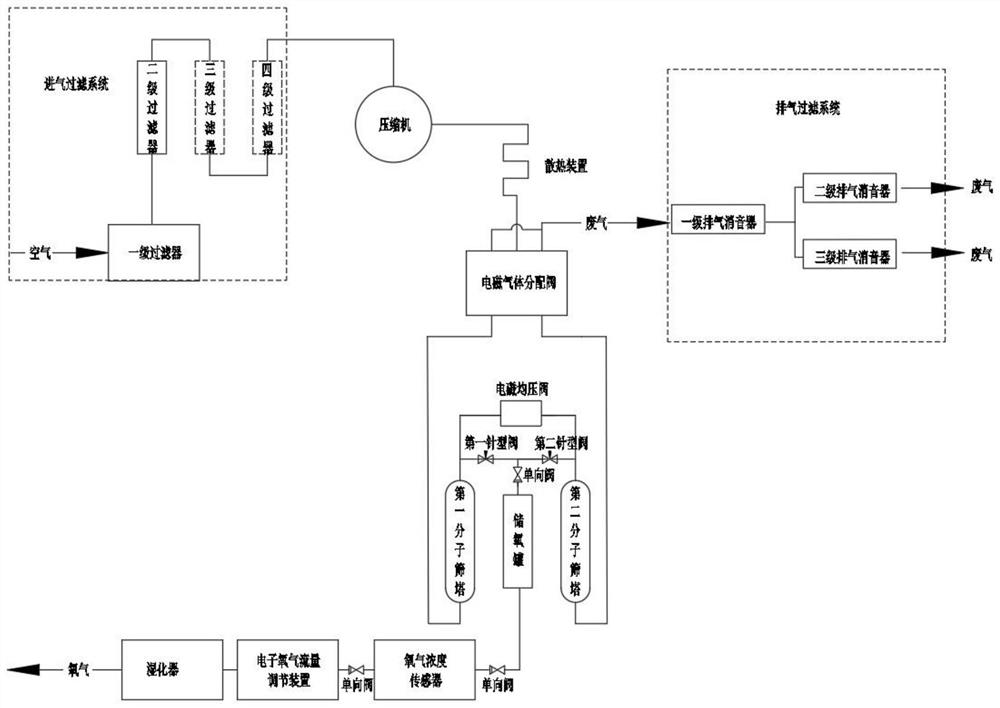

[0032] It is one of the specific implementation modes of the present invention: refer to the accompanying drawings.

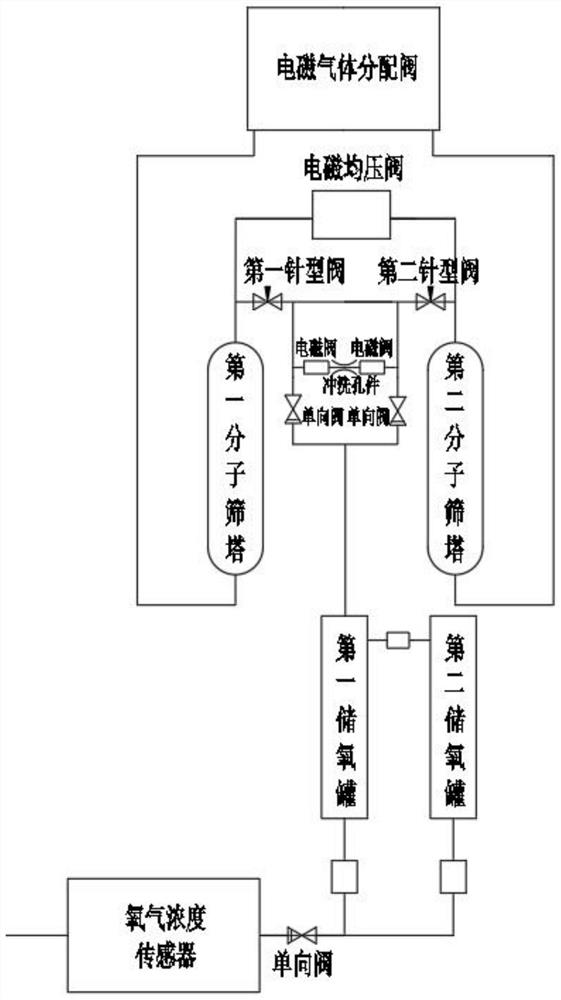

[0033] In this embodiment, a digital intelligent oxygen production system includes an air intake filter system, a compressor, a cooling device, an electromagnetic gas distribution valve, an exhaust filter system, a first molecular sieve tower, a second molecular sieve tower, and an oxygen storage tank , an electromagnetic pressure equalizing valve assembly, a one-way valve control assembly, an oxygen concentration sensor, an electronic oxygen flow regulating device, and a humidifier. The air inlet of the electromagnetic gas distribution valve is connected, the first gas inlet and outlet of the electromagnetic gas distribution valve are connected with the first molecular sieve tower, the second gas inlet and outlet of the electromagnetic gas distribution valve are connected with the second molecular sieve tower, and the first gas inlet and outlet of the electroma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com