Low-damage machining method based on sapphire crystal orientation and machining direction synergistic principle

A processing method and technology of processing direction, applied in the direction of stone processing equipment, manufacturing tools, fine working devices, etc., can solve the problems of high hardness and high brittleness of sapphire materials, which are easy to be damaged, and improve the grinding surface of sapphire. quality, reduced likelihood, reduced grinding force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in specific embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

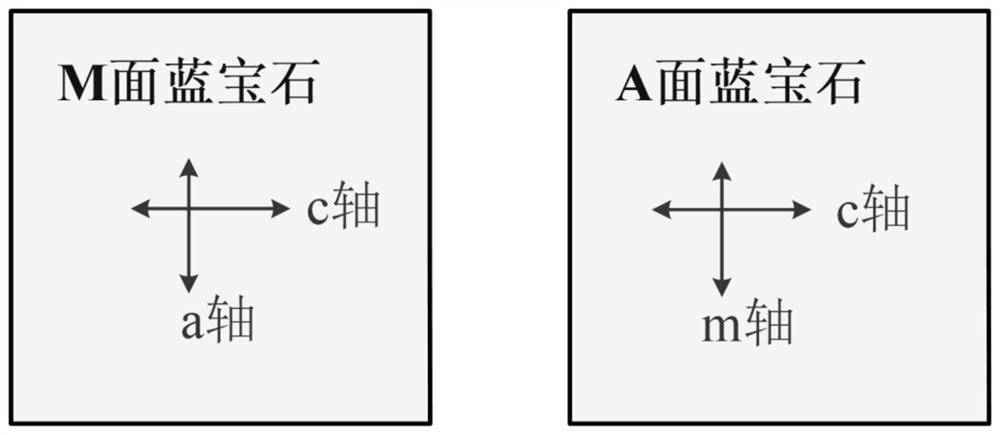

[0022] A low-damage processing method for coordinating a processing direction and a sapphire crystal orientation, the sapphire is an A-face sapphire and / or an M-face sapphire, and the processing method comprises the following steps:

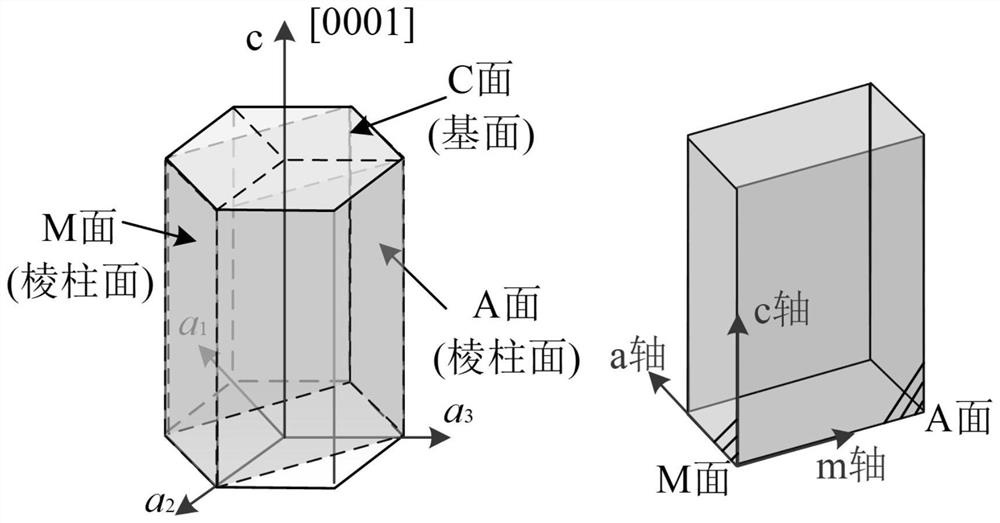

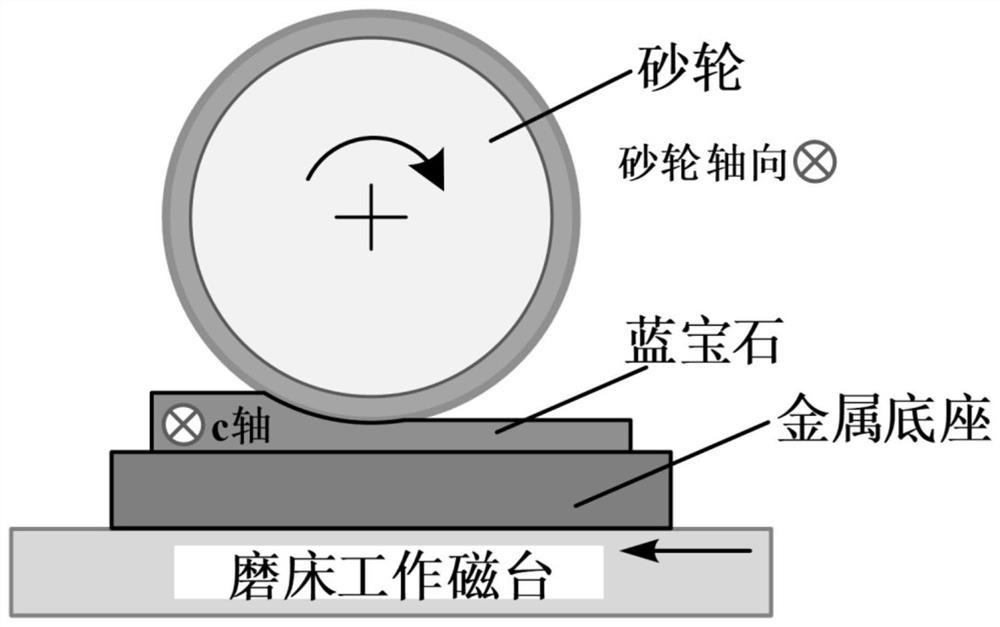

[0023] Step S1. Before the sapphire is processed, use an X-ray crystal orientation instrument to orient the sapphire, and the orientation error is less than 30", the spatial positions of the A surface, the M surface, and the C surface of the sapphire and the schematic diagram of cutting the sapphir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com