A Grinding Method Based on Surface Oxidation of SICP/Al Composite

A composite material, surface oxidation technology, applied in anodizing, surface reaction electrolytic coating, electrolytic coating, etc., can solve the problems of difference in grinding removal rate, embedded defects, surface quality damage, etc., to improve the grinding surface quality, avoid grinding The effect of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

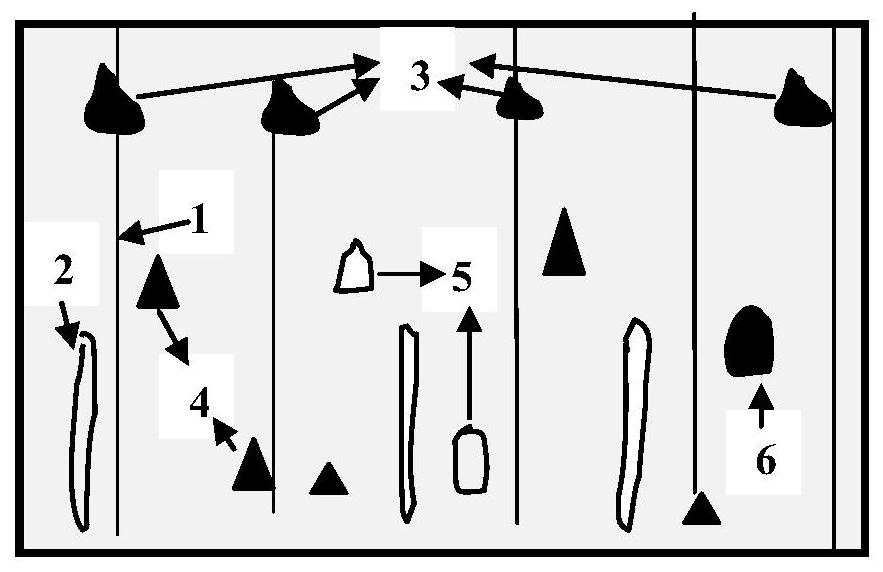

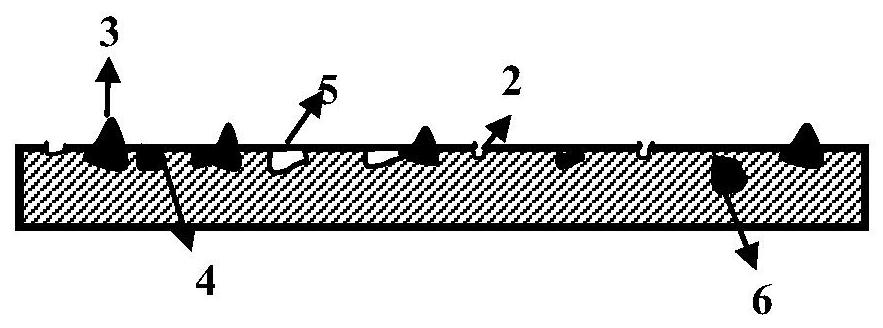

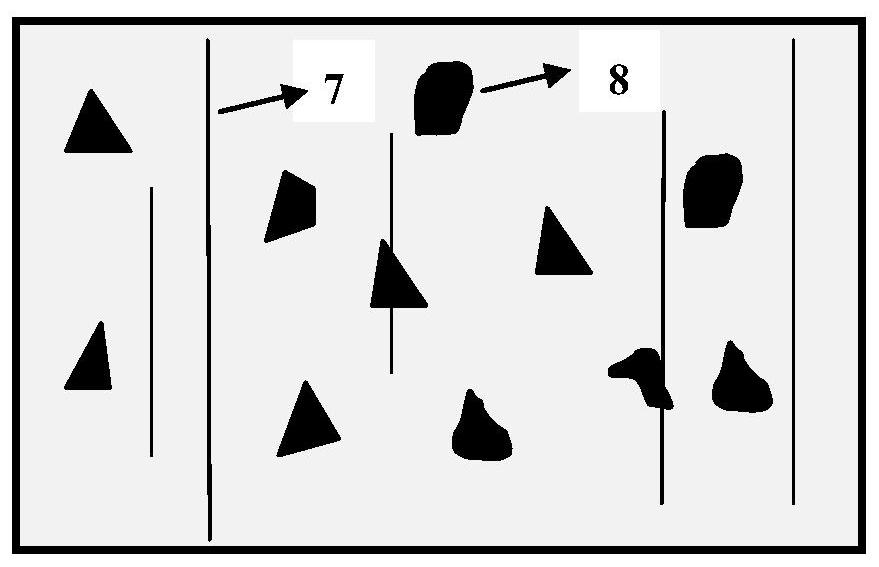

Method used

Image

Examples

Embodiment 1

[0028] (1) Perform conventional anodic oxidation pretreatment process on the SiCp / Al composite material sample. Mechanical polishing, alkali washing, water washing, pickling, water washing to get a clean surface. Alkali washing uses 7% NaOH solution at a temperature of 50°C, and pickling uses a 50% nitric acid solution at room temperature.

[0029] The pretreated SiCp / Al composite material sample was used as the anode, and the lead plate was used as the cathode, and anodized in an anodic oxidation solution to obtain Al on the surface. 2 o 3 SiCp / Al composite material of oxide ceramic film, the thickness of the ceramic film is 10μm, the thickness of the dense inner layer is 3μm, the porous outer layer is 7μm, and the surface hardness is 1000HV. Among them, the composition of the anodic oxidation aqueous solution is: sulfuric acid 200g / L, oxalic acid 1.5g / L, glycerin 3ml / L, and the process parameters are: voltage 15V, temperature 20°C, and treatment time 60min.

[0030]Wash a...

Embodiment 2

[0032] The conventional micro-arc oxidation pretreatment process was carried out on the SiCp / Al composite material sample. Adopt conventional micro-arc oxidation pretreatment process, grinding and polishing, ultrasonic cleaning, water washing. Grinding and polishing use 200#, 400#, 600#, 800#, 1000# sandpaper, use acetone for ultrasonic cleaning, and use deionized water for washing.

[0033] The pretreated SiCp / Al composite material sample was used as the anode, and the stainless steel was used as the cathode, and the micro-arc oxidation treatment was carried out in the micro-arc oxidation solution to obtain Al on the surface. 2 o 3 The SiCp / Al composite material of the oxide ceramic film has a film thickness of 40 μm, among which, the thickness of the dense layer is 10 μm, the loose layer is 30 μm, and the surface hardness is 2800HV. Include 10g / L Na in the micro-arc oxidation aqueous solution 2 SiO 3 , 2g / L KOH, Na 2 WO 4 2g / L, nano-SiC particles 1.5g / L, temperature 25...

Embodiment 3

[0039] The conventional anodic oxidation pretreatment process was carried out on the SiCp / Al composite material sample. Mechanical polishing, alkali washing, water washing, pickling, water washing to get a clean surface. Alkali washing uses 7% NaOH solution at a temperature of 50°C, and pickling uses a 50% nitric acid solution at room temperature.

[0040] The pretreated SiCp / Al composite material sample was used as the anode, and the lead plate was used as the cathode, and anodized in an anodic oxidation solution to obtain Al on the surface. 2 o 3 The SiCp / Al composite material of the oxide ceramic film, the thickness of the ceramic film is 50 μm, the thickness of the dense inner layer is 10 μm, the porous outer layer is 40 μm, and the surface hardness is 700HV. Among them, the composition of the anodic oxidation aqueous solution is: sulfuric acid 300g / L, oxalic acid 2g / L, glycerin 5ml / L, and the process parameters are: voltage 20V, temperature 20°C, and treatment time 120m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com