A grinding method for a high-precision counter-grinding and brushing machine

A brush and plate machine technology, applied in the direction of grinding machine tools, grinding devices, metal processing equipment, etc., can solve problems such as poor grinding, products that do not meet quality requirements, substrate deformation, etc., to improve product quality and avoid grinding defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

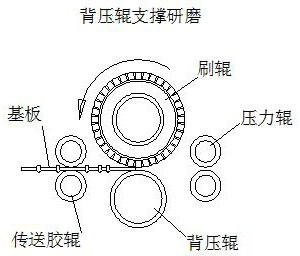

[0027] In this example, if Figure 8 As shown, the high-precision brushing machine used in the present invention includes a frame 1, a first sliding mechanism and a second sliding mechanism arranged on the frame 1, the first sliding mechanism and the second sliding mechanism The two sliding mechanisms are respectively provided with an upper brush roller 2 and a lower brush roller 3, the upper brush roller 2 and the lower brush roller 3 are arranged in parallel and are located on the same vertical plane, and the high-precision brushing machine also includes The power device connected with the transmission of the upper brush roller 2 and the lower brush roller 3, the upper brush roller 2 and the lower brush roller 3 are provided with a processing gap, and the front end of the processing gap is provided with a feeding mechanism 4, The rear end of the processing gap is provided with a discharge mechanism 5, the feed mechanism 4 and the discharge mechanism 5 are both arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com