CVD diamond grinding wheel with surface ordered micro structure

A diamond grinding wheel and micro-structure technology, applied in the field of diamond grinding wheels, can solve the problems of reducing the number of effective grinding edges of the grinding wheel, affecting the machining surface accuracy, and the difference in the height of the grinding edges, so as to reduce heat accumulation, improve grinding accuracy, and reduce surface area. Effects of heat damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the invention will be further described below in conjunction with the drawings.

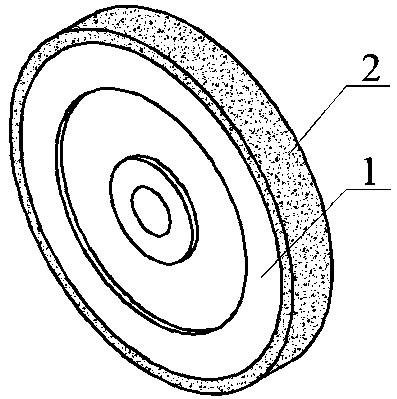

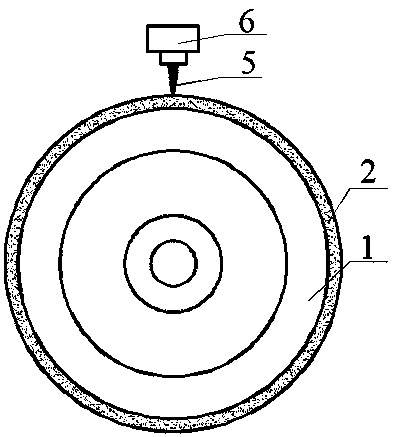

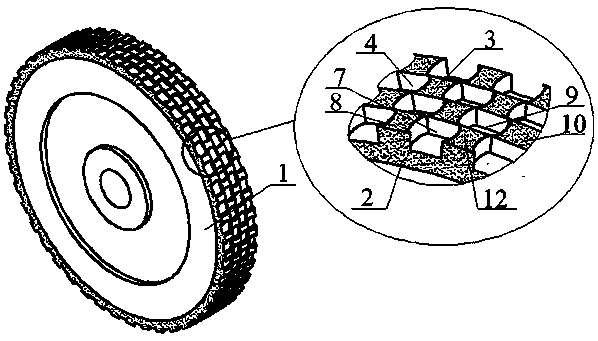

[0024] See Figure 1 to Figure 5 , A CVD diamond grinding wheel with ordered microstructured surface, characterized in that: the grinding wheel is composed of a hub 1, a diamond film 2, a large number of micro grinding units 3 and micro grooves 4; a layer is deposited on the outer circumference of the hub 1 Diamond film 2; a large number of microgrooves 4 are machined on the outer circumferential surface of the diamond film, and the grinding unit 3 is between two adjacent microgrooves 4, and the microgrooves 4 and the grinding unit 3 are arranged in staggered order; all The top surface of the grinding unit 3 has a waist shape 12. When the grinding wheel grinds the workpiece 11, the grinding unit 3 undertakes the work of cutting the surface 13 of the workpiece, and the microgrooves 4 mainly play the role of holding chips and storing liquid; the orderly arrangement ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com