Cutting-tool equal-height adjustment tool and numerical control countersink mechanism

A technology for adjusting tools and knives, which is applied in the direction of manufacturing tools, metal processing machine parts, boring/drilling, etc. It can solve problems such as difficult product quality, unequal tool height, and difficult contour adjustment, and achieves a simple overall structure, Easy to adjust, high performance of cutting tool etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

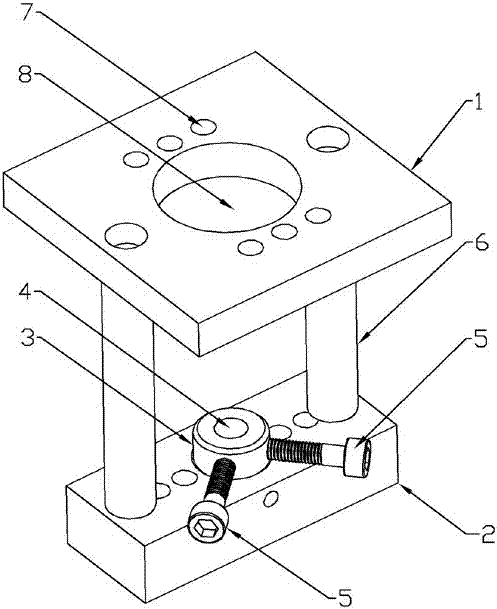

[0016] Such as figure 1 As shown, in this embodiment, the tool contour adjustment tool includes a top plate 1, a base 2 arranged below the top plate 1, and a tool positioning block 3 arranged on the base 2, and the tool positioning block 3 There is a positioning hole 4 matching the tool, and at least one positioning screw 5 is provided on the side of the tool positioning block 3, and the positioning screw 5 is threadedly connected to the side of the tool positioning block 3, and the The tail of the positioning screw 5 is threadedly connected to the side of the tool positioning block 3 and communicated with the positioning hole 4. At least one connecting column 6 is arranged between the top plate 1 and the base 2, and the top plate 1 is provided with several installation holes 7 and a tool mounting seat give way hole 8.

[0017] In this embodiment, two positioning screws 5 are provided on the side of the tool positioning block 3, and the two positioning screws 5 are arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com