A grinding method capable of eliminating grinding cracks

A technology for grinding and grinding cracks, applied in the field of grinding, which can solve problems such as affecting production and installation speed, easy occurrence of grinding cracks, and failure to install normally, so as to optimize processing steps and operating skills, and increase heat dissipation. Spaces and channels, the effect of increasing cooling channels and spaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

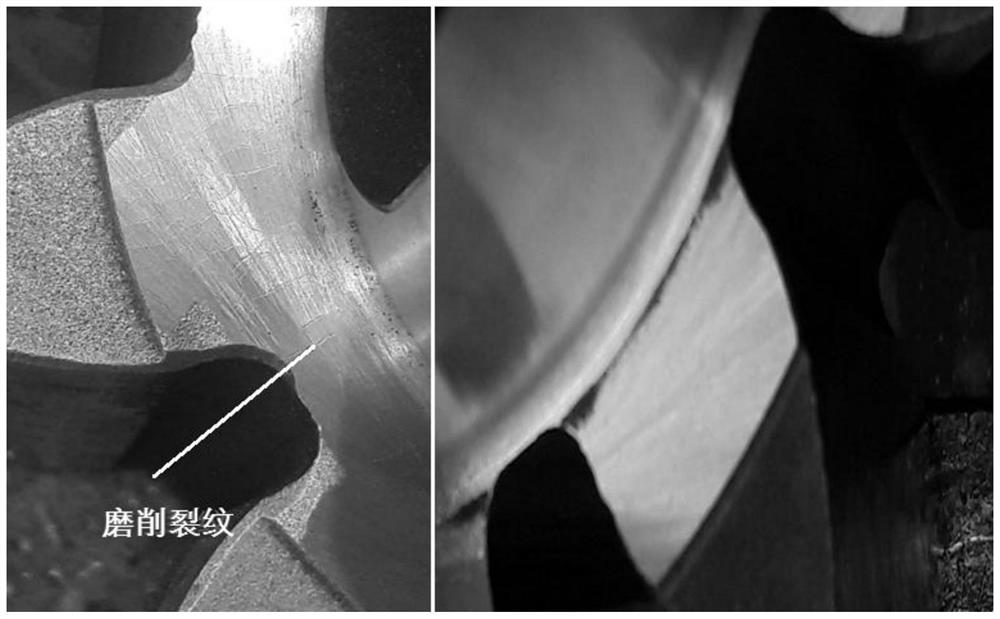

Image

Examples

Embodiment 1

[0029] A grinding method capable of eliminating grinding cracks, used for grinding carburized parts, comprising the steps of:

[0030] Step 1, reduce the workpiece speed: reduce the workpiece speed from the standard speed of 300 rpm to 150 rpm during normal grinding, so as to slow down the processing speed and frequency, reduce the speed of grinding heat, and avoid rapid heat generation. accumulation;

[0031] Step 2, turn the angle of the grinding head: turn the angle of the grinding head so that the grinding side of the grinding wheel forms a slight angle with the surface of the workpiece to be ground. The slight angle is controlled at about 0.5°, so that the heat can quickly Diffusion out without affecting processing efficiency and precision;

[0032] Step 3, dressing the side of the grinding wheel: use a diamond pen to trim the grinding surface of the grinding wheel into a concave shape, so that the outer edge of the grinding wheel is the highest, and form point contact w...

Embodiment 2

[0038] A grinding process capable of eliminating grinding cracks is used for grinding a quenched high-carbon steel workpiece, comprising the steps of:

[0039] Step 1, reduce the workpiece speed: reduce the workpiece speed from the standard speed of 280 rpm to 170 rpm during normal grinding, so as to slow down the processing speed and frequency, reduce the speed of grinding heat, and avoid rapid heat generation. accumulation;

[0040] Step 2, turn the angle of the grinding head: turn the angle of the grinding head so that the grinding side of the grinding wheel forms a slight angle with the surface of the workpiece to be ground. Diffusion out without affecting processing efficiency and precision;

[0041] Step 3, dressing the side of the grinding wheel: Use a diamond pen to trim the grinding surface of the grinding wheel into a concave shape, so that the outer edge of the grinding wheel is the highest, and form point contact with the grinding surface during the grinding process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com