Infrared window anti-reflection protective film

An infrared window and protective film technology, applied in the field of infrared optoelectronics, can solve the problems of window surface damage, optical system failure, poor weather resistance of infrared windows, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

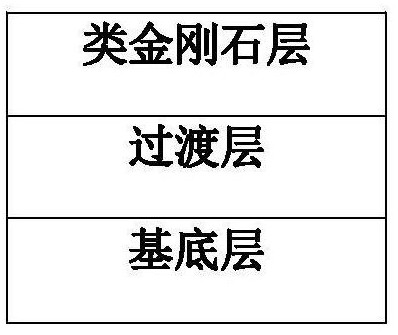

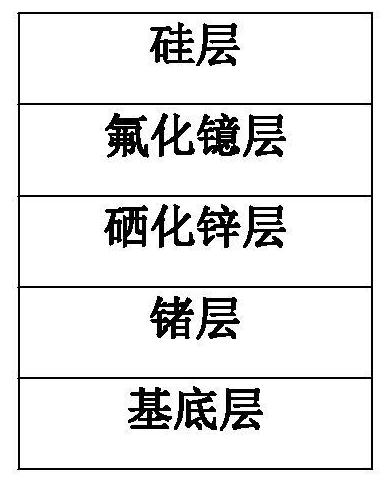

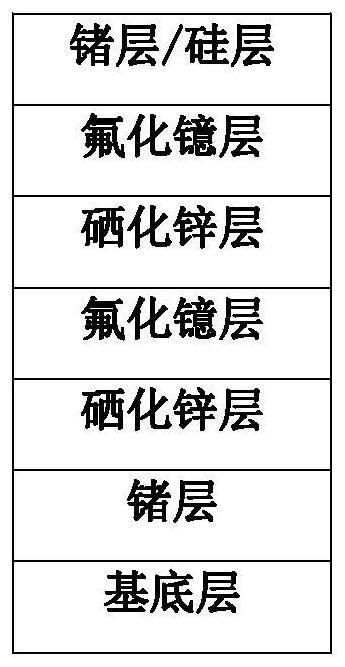

[0021] The invention provides an infrared window anti-reflection protective film, such as figure 1 As shown, it includes a base layer, a transition layer and a diamond-like layer; the base layer is deposited by physical vapor deposition of chalcogenide materials, germanium or silicon materials, and argon is used for ion assistance during the deposition process to increase the film layer The compactness of the film, while reducing the stress of the film; the material of the transition layer is germanium, silicon, zinc selenide and ytterbium fluoride, divided into four-layer structure, six-layer structure and eight-layer structure; the diamond-like layer It is prepared by chemical vapor deposition, butane is used as the gas source, and argon is used as the carrier gas for deposition, and the ratio of the two and the radio frequency power are controlled during the deposition process. The structure of the protective film layer is very simple, and the deposition efficiency is high;...

Embodiment 2

[0025] The invention provides an infrared window anti-reflection protective film, such as figure 1 As shown, it includes a base layer, a transition layer and a diamond-like layer; the base layer is deposited by physical vapor deposition of chalcogenide materials, germanium or silicon materials, and argon is used for ion assistance during the deposition process to increase the film layer The compactness of the film, while reducing the stress of the film; the material of the transition layer is germanium, silicon, zinc selenide and ytterbium fluoride, divided into four-layer structure, six-layer structure and eight-layer structure; the diamond-like layer It is prepared by chemical vapor deposition, butane is used as the gas source, and argon is used as the carrier gas for deposition, and the ratio of the two and the radio frequency power are controlled during the deposition process. The structure of the protective film layer is very simple, and the deposition efficiency is high;...

Embodiment 3

[0029] The invention provides an infrared window anti-reflection protective film, such as figure 1 As shown, it includes a base layer, a transition layer and a diamond-like layer; the base layer is deposited by physical vapor deposition of chalcogenide materials, germanium or silicon materials, and argon is used for ion assistance during the deposition process to increase the film layer The compactness of the film, while reducing the stress of the film; the materials of the transition layer are germanium, silicon, zinc selenide and ytterbium fluoride, which are divided into four-layer structure, six-layer structure and eight-layer structure; the diamond-like carbon layer It is prepared by chemical vapor deposition, butane is used as the gas source, and argon is used as the carrier gas for deposition, and the ratio of the two and the radio frequency power are controlled during the deposition process. The film structure of the protective film is very simple, and the deposition e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com