a two-dimensional cd 7 te 7 cl 8 o 17 Crystal material and preparation method thereof

A crystal material and downstream technology, applied in the field of two-dimensional Cd7Te7Cl8O17 crystal material and its preparation, can solve the problems of difficult crystal material synthesis technology, lack of two-dimensional Cd, etc., to overcome mechanical stripping, simple and easy reaction, and overcome solid phase The effect of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

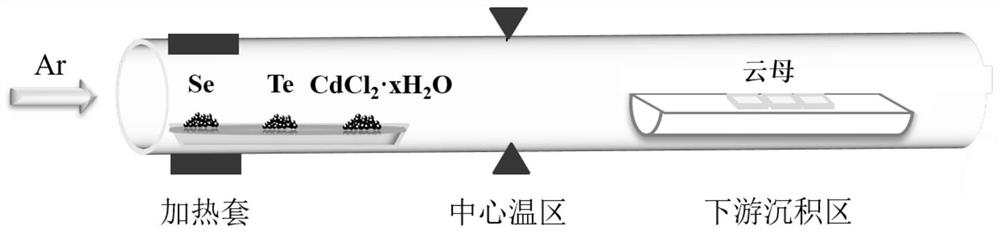

[0027] see figure 1 , the two-dimensional Cd provided by the present invention 7 Te 7 Cl 8 o 17 A preparation method for crystal materials, the preparation method mainly includes the following steps: firstly, divide the reflection area of the tube furnace into an upstream low temperature area, a central temperature area and a downstream deposition area in the horizontal direction, and divide cadmium chloride, tellurium powder and Selenium powder is placed in the upstream low-temperature area as a precursor; then, cadmium chloride, tellurium powder and selenium powder react to form Cd 7 Te 7 Cl 8 o 17 crystalline material, using a carrier gas to convert Cd 7 Te 7 Cl 8 o 17 The crystalline material is brought into the downstream deposition zone to be deposited on the substrate located in the downstream deposition zone, resulting in two-dimensional Cd 7 Te 7 Cl 8 o 17 crystal material.

[0028] In this embodiment, the tubular furnace is provided with a heating jack...

Embodiment 1

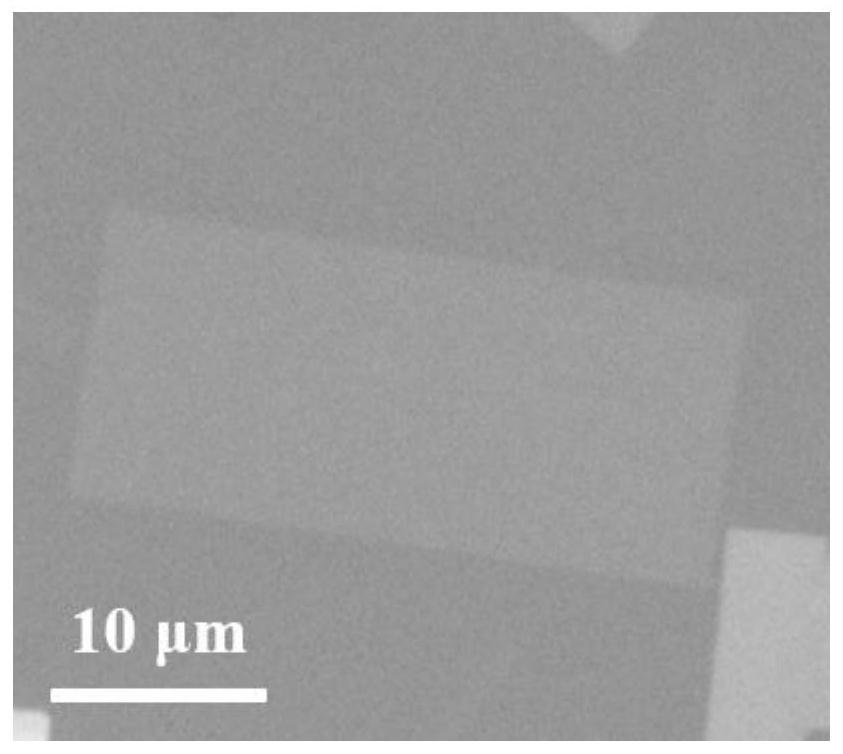

[0037] The two-dimensional Cd provided by Example 1 of the present invention 7 Te 7 Cl 8 o 17 The preparation method of the crystal material adopts a single temperature zone horizontal tube furnace as the reaction device. The tube length of the horizontal tube furnace is 90cm, the outer diameter is 25mm, the tube wall thickness is 2mm, the range of the constant temperature zone is 10cm, and the temperature in the central temperature zone 800°C, the temperature of the downstream deposition zone is 500°C, and the heating rate is 40°C / min.

[0038] Embodiment 1 of the present invention adopts CdCl 2 , Te and Se powders (purity>99.99%) are used as precursors, which are placed in the upstream low-temperature area in sequence. At the same time, the outer periphery of the horizontal tube furnace corresponding to the Se powder is equipped with a heating mantle, and the temperature of the heating mantle is 400 ° C; using fluorphlogopite As a substrate, it is placed downstream at a ...

Embodiment 2

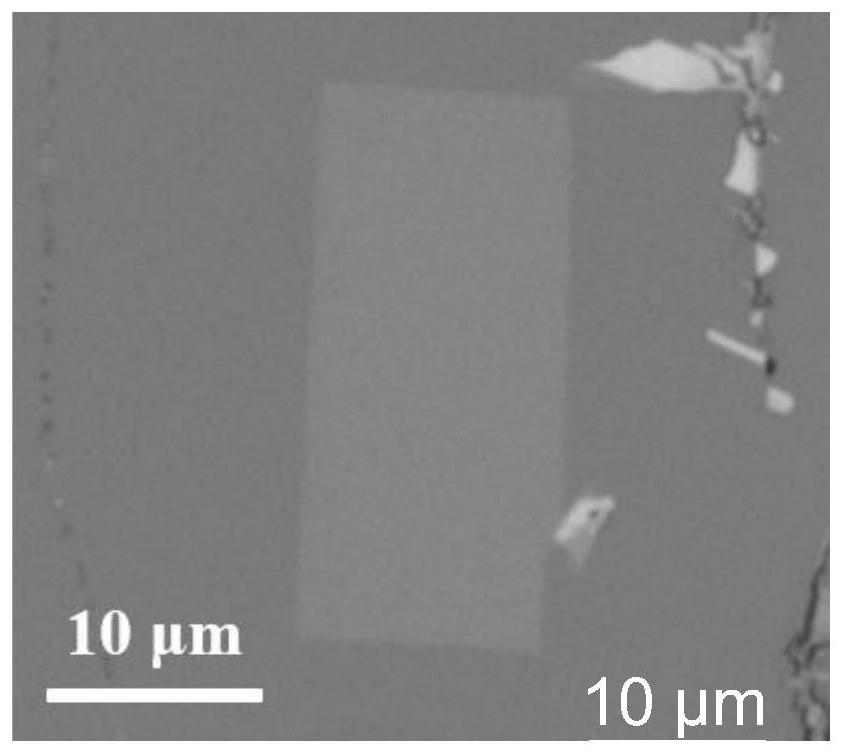

[0040] Embodiment 2 of the present invention provides a horizontal tube furnace with a single temperature zone as the reaction device. The tube length of the horizontal tube furnace is 90 cm, the outer diameter is 25 mm, the tube wall thickness is 2 mm, the constant temperature zone range is 10 cm, and the central temperature zone The temperature is 825°C, the temperature in the downstream deposition zone is 550°C, and the heating rate is 40°C / min.

[0041] Embodiment 2 of the present invention adopts CdCl 2 , Te and Se powders (purity>99.99%) are used as precursors, which are placed in the upstream low-temperature area in turn, and a heating jacket is installed in the horizontal tube furnace area corresponding to the Se powder. The bottom is placed 16cm downstream from the central temperature zone. Before the reaction, pre-evacuate to about 10Pa, then fill with 600 sccm of Ar to atmospheric pressure, and repeatedly wash the air to remove residual air; during the reaction pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com