Preparation method of easy-to-peel ultra-thin carrier-attached copper foil with pure interface

A technology of carrier copper foil and ultra-thin copper foil is applied in the field of preparation of ultra-thin copper foil with carrier, which can solve the problems of tearing of carrier copper foil, high peeling strength of peeling layer, adhesion of ultra-thin copper foil, etc. The effect of surface flatness, stable peeling performance and pure interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

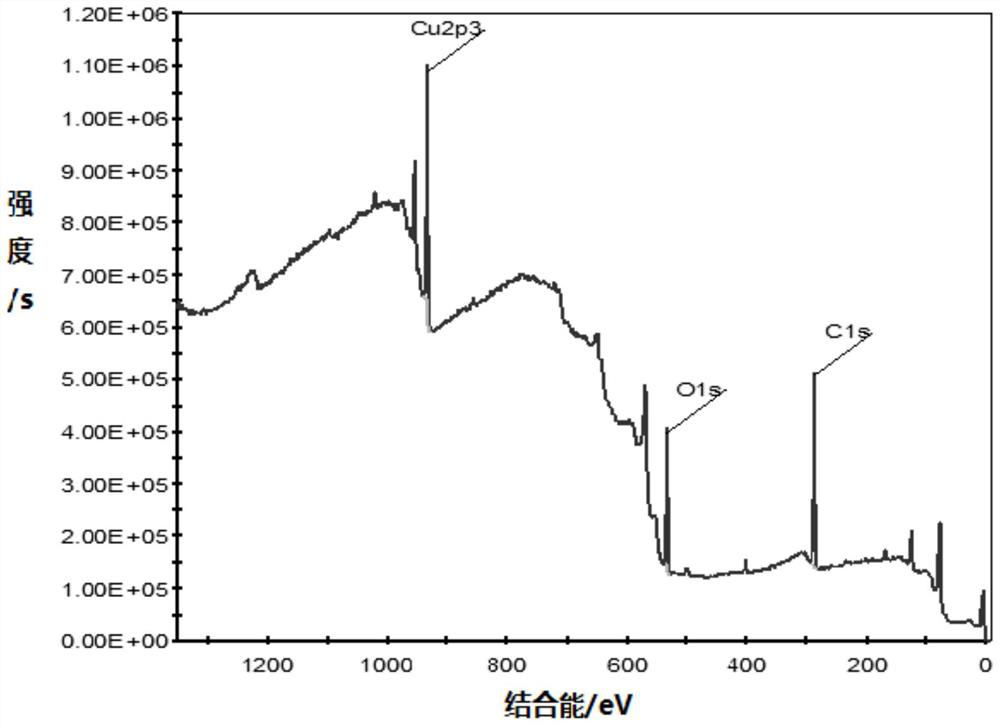

[0041] According to a preferred embodiment of the present invention, the organic layer contains an organic compound with a ring structure, preferably selected from organic compounds containing five-membered rings and / or six-membered rings, more preferably selected from melamine, benzotriazole, At least one of benzimidazole, 6-chloro-1-hydroxybenzotriazole and 1H-1,2,3-triazole.

[0042] According to the present invention, preferably, the alloy layer is obtained by electroplating from an alloy solution containing a complexing agent and at least one soluble sulfate.

[0043] In some embodiments of the present invention, preferably, based on the total amount of the alloy liquid, the content of soluble sulfate in the alloy liquid is 10-200g / L, preferably 30-80g / L; The content is 50-300g / L, preferably 150-200g / L. Optimum conditions are more conducive to obtaining a uniform alloy layer deposited on the surface, and are beneficial to reducing the surface roughness of the ultra-thin ...

Embodiment 1

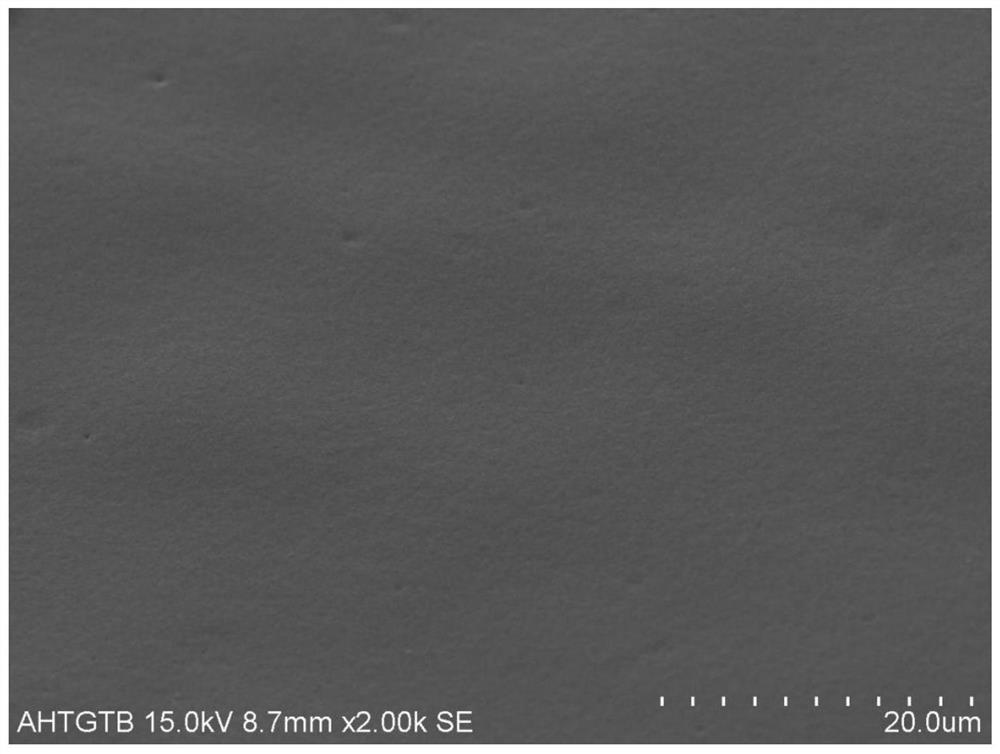

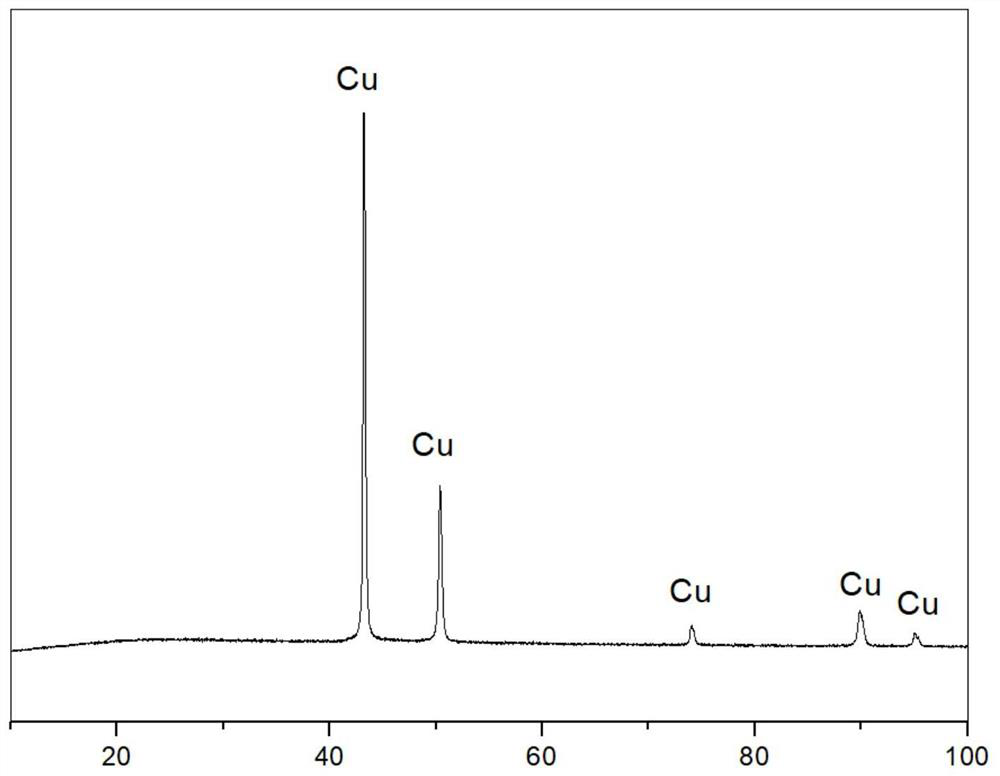

[0100] (1) Preparation of carrier copper foil

[0101] Pickling treatment: Dilute the concentrated sulfuric acid to dilute sulfuric acid with a concentration of 10vol.%, pump it into the pickling tank, soak the copper foil with a thickness of 18 μm in the pickling tank, and surface the copper foil with deionized water after soaking For cleaning, the transmission speed of the conveying roller is 20m / min, and the circulation rate of the treatment liquid in each tank is 15L / min;

[0102] Electroplating treatment: the cleaned copper foil enters the electroplating tank filled with alloy solution for electroplating, wherein the concentration of nickel sulfate in the alloy solution is 15g / L, the concentration of zinc sulfate is 60g / L, and the concentration of potassium pyrophosphate is 180g / L , the conditions of the electroplating treatment include: the temperature is 30°C, and the current density is 3A / dm 2 , the time is 5s;

[0103] Coating treatment: After the copper foil afte...

Embodiment 2

[0115] (1) Preparation of carrier copper foil

[0116] Pickling treatment: Dilute the concentrated sulfuric acid to dilute sulfuric acid with a concentration of 10vol.%, pump it into the pickling tank, soak the copper foil with a thickness of 18 μm in the pickling tank, and surface the copper foil with deionized water after soaking For cleaning, the transmission speed of the conveying roller is 15m / min, and the circulation rate of the treatment liquid in each tank is 20L / min;

[0117] Electroplating treatment: the cleaned copper foil enters the electroplating tank filled with alloy solution for electroplating, wherein the concentration of cobalt sulfate in the alloy solution is 20g / L, the concentration of zinc sulfate is 30g / L, and the concentration of sodium citrate is 60g / L , the conditions of the electroplating treatment include: the temperature is 35°C, and the current density is 4A / dm 2 , the time is 4s;

[0118] Coating treatment: After the copper foil after the elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com