Airgel coating and preparation method thereof and airgel coating and preparation method thereof

A technology of airgel and airgel powder, which is applied in coatings, fireproof coatings, cement production, etc., can solve the problem of limited contact of composite insulation boards, lack of adhesiveness and coating properties of plate materials, and airgel The problem of small amount of doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

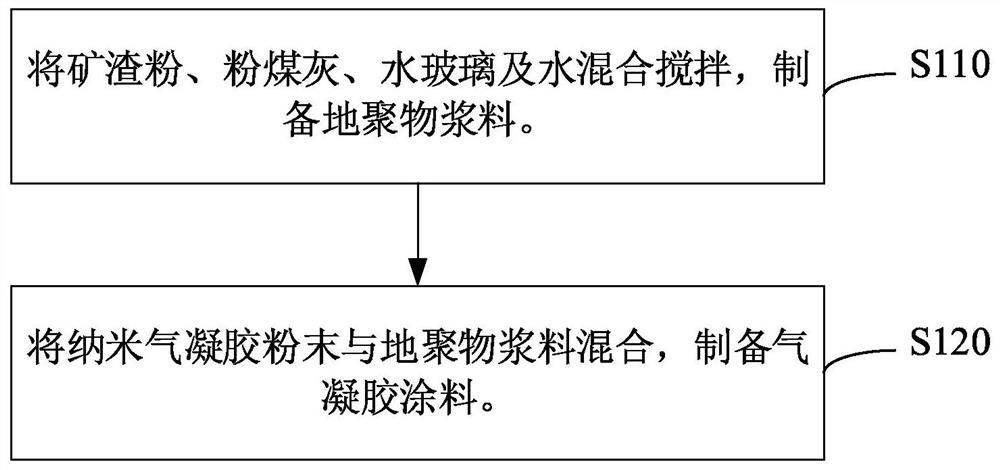

[0034] see figure 1 , the preparation method of the airgel coating of an embodiment, comprises the steps:

[0035] Step S110: Mix and stir slag powder, fly ash, water glass and water to prepare geopolymer slurry.

[0036] The step of mixing and stirring slag powder, fly ash, water glass and water comprises: first mixing slag powder, fly ash and water glass with a mass ratio of 4:(0.2~4):(0.5~2) to prepare dry powder, and then mix the dry powder with water, the mass ratio of the dry powder to water is 1: (0.2-0.5).

[0037] Specifically, in the step of mixing slag powder, fly ash and water glass, they are mixed in a dry powder mixer.

[0038] In the step of mixing the dry powder and water, stir in a high-speed mixer for 2 minutes to 10 minutes, so that the geopolymer slurry is mixed evenly and there are no large particles.

[0039] The above-mentioned geopolymer slurry has the advantages of high compressive strength (30MPa-100MPa), high temperature resistance (not lower than...

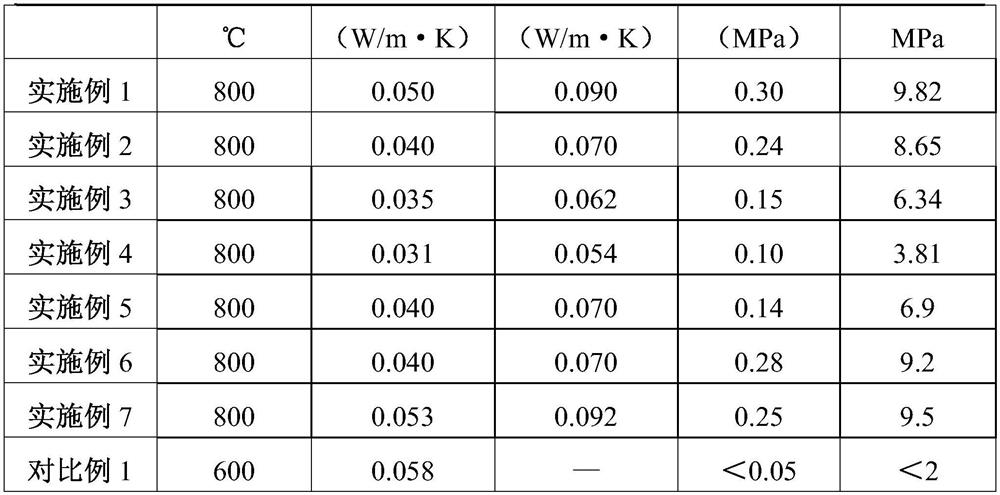

Embodiment 1

[0079] The preparation process of the airgel coating of the present embodiment is specifically as follows:

[0080] (1) Mix ethyl orthosilicate and ethanol evenly to form solution A, then add deionized water dropwise to solution A (molar ratio of ethyl orthosilicate, ethanol to water is 1:10:5), add Hydrochloric acid was used to adjust the pH to 2, and after the sol was formed, ammonia water was added to adjust the pH to 8 to prepare a silica gel. After aging the silica gel in ethanol for 2 days, 2 Drying was carried out (the drying temperature was 40° C. and the pressure was 9 MPa) to prepare an airgel block.

[0081] (2) Heat-treating the airgel block in a tube furnace at 500° C. for 1 hour to obtain a high-temperature-resistant airgel block. The high temperature resistant airgel block is made into airgel powder by ball milling method.

[0082] (3) Grinding blast furnace slag into fine slag powder by means of ball milling and physical screening. Mix fine slag powder, fly ...

Embodiment 2

[0087] The preparation process of the airgel coating of the present embodiment is specifically as follows:

[0088](1) Mix ethyl orthosilicate and ethanol evenly to form solution A, then add deionized water dropwise into solution A (molar ratio of ethyl orthosilicate, ethanol, water 1:10:5), adjust the pH After the sol is formed, add SiC powder (the molar ratio of SiC to tetraethyl orthosilicate is 0.06:1), and continue stirring to disperse. After the sol is formed, add ammonia water to adjust the pH to 8 to prepare silica gel. The silica gel was aged in ethanol for 2 days, and then subjected to supercritical CO 2 Drying was carried out (the drying temperature was 40° C. and the pressure was 9 MPa) to prepare an airgel block.

[0089] (2) Heat-treating the airgel block in a tube furnace at 500° C. for 1 hour to obtain a high-temperature-resistant airgel block. The airgel block is made into airgel powder by ball milling method.

[0090] (3) Grinding blast furnace slag into f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com