Method, product and application of cellulose/sodium alginate composite airgel prepared from bamboo shoot leftovers

A technology of composite aerogel and sodium alginate, applied in the field of biomass aerogel materials, can solve the problems of difficult cellulose, limited application value of single cellulose aerogel, etc., achieve mild reaction conditions, easy industrial operation, A wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

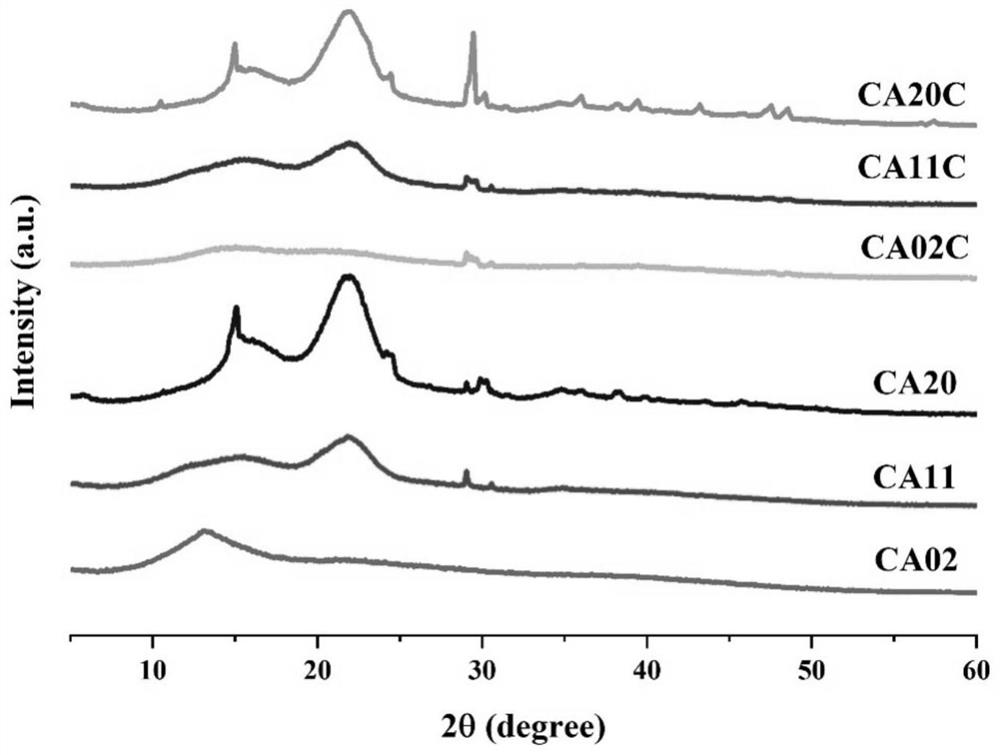

Image

Examples

Embodiment 1

[0047] The leftovers of bamboo shoots were washed with clear water, sliced into slices, dried at 80°C for 24 hours, and then pulverized with a mill to pass through a 60-mesh sieve to obtain bamboo shoot powder. Weigh 60g of bamboo shoot powder, add deionized water according to the mass ratio of solid to liquid 1:30, heat at 80°C for 50min and then filter, repeat the operation 3 times and then dry at 80°C for 18h. Add deionized water to the obtained product according to the mass ratio of solid to liquid 1:20, then add sodium chlorite with the same mass as the product, adjust the pH to 4 with glacial acetic acid, bleach at 75°C for 2 hours, then add deionized water to terminate the reaction , washed with a large amount of deionized water until neutral, and then dried at 70°C for 18h to obtain bamboo shoot cellulose heddle fibers. Bamboo shoot cellulose heald fibers and 10% potassium hydroxide solution are mixed evenly according to the mass volume ratio of 1g:10ml, after alkali...

Embodiment 2

[0050] The leftovers of bamboo shoots were washed with clear water, sliced into slices, dried at 80°C for 24 hours, and then pulverized with a mill to pass through a 60-mesh sieve to obtain bamboo shoot powder. Weigh 60g of bamboo shoot powder, add deionized water according to the mass ratio of solid to liquid 1:30, heat at 80°C for 50min and then filter, repeat the operation 3 times and then dry at 80°C for 18h. Add deionized water to the obtained product according to the mass ratio of solid to liquid 1:20, then add sodium chlorite with the same mass as the product, adjust the pH to 4 with glacial acetic acid, bleach at 75°C for 2 hours, then add deionized water to terminate the reaction , washed with a large amount of deionized water until neutral, and then dried at 70°C for 18h to obtain bamboo shoot cellulose heddle fibers. Bamboo shoot cellulose heald fibers and 10% potassium hydroxide solution are mixed evenly according to the mass volume ratio of 1g:10ml, after alkali...

Embodiment 3

[0053] The leftovers of bamboo shoots were washed with clear water, sliced into slices, dried at 80°C for 24 hours, and then pulverized with a mill to pass through a 60-mesh sieve to obtain bamboo shoot powder. Weigh 60g of bamboo shoot powder, add deionized water according to the mass ratio of solid to liquid 1:30, heat at 80°C for 50min and then filter, repeat the operation 3 times and then dry at 80°C for 18h. Add deionized water to the obtained product according to the mass ratio of solid to liquid 1:20, then add sodium chlorite with the same mass as the product, adjust the pH to 4 with glacial acetic acid, bleach at 75°C for 2 hours, then add deionized water to terminate the reaction , washed with a large amount of deionized water until neutral, and then dried at 70°C for 18h to obtain bamboo shoot cellulose heddle fibers. Bamboo shoot cellulose heald fibers and 10% potassium hydroxide solution are mixed evenly according to the mass volume ratio of 1g:10ml, after alkali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com