High-impermeability cement-based repairing mortar with crack self-sealing function and preparation method

A repairing mortar and self-sealing technology, applied in the field of building materials, can solve the problems of easy cracking and inability to self-sealing cracks, etc., and achieve the effect of improving the impermeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

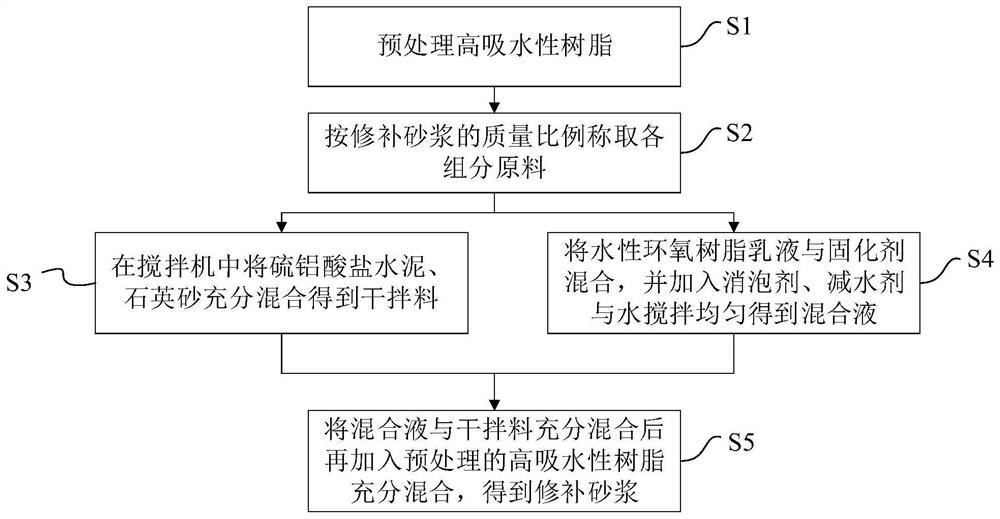

Method used

Image

Examples

Embodiment 1

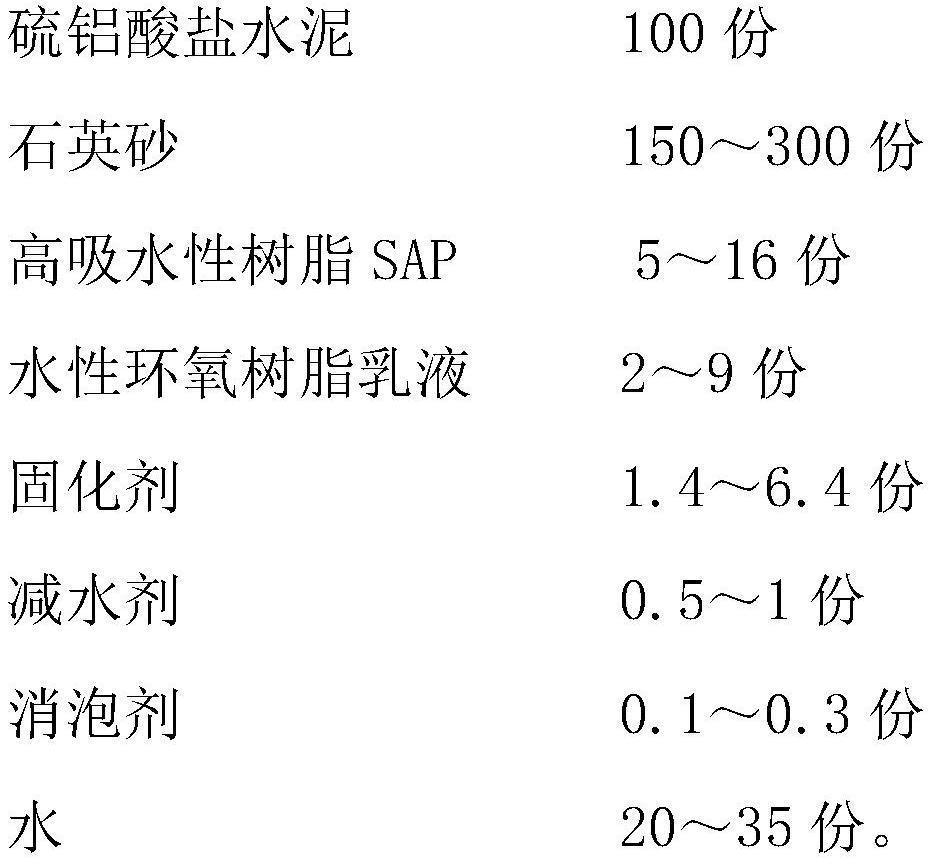

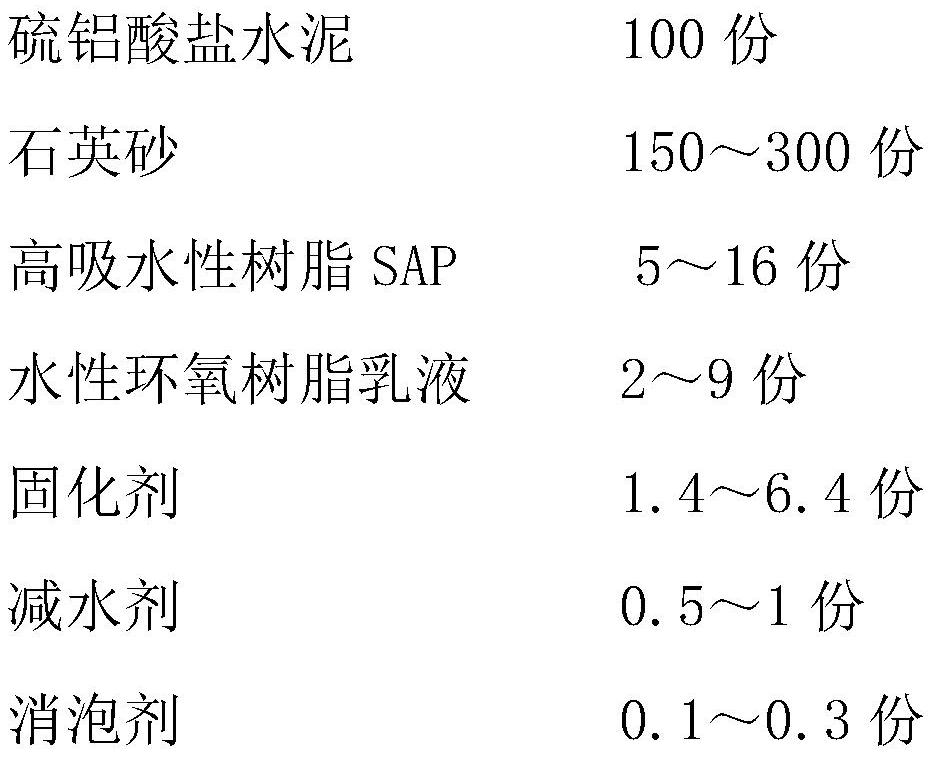

[0054](1) Preparation of raw materials: 100 parts of sulfur-aluminate cement, 300 pieces of quartz sand, 5 parts of SAP, 4.5 water-based epoxy emulsions, 3.2 parts of curing agent, 0.8 parts of water reducer, 30 water, 30 parts of water Silicone foaming agent 0.1 parts.

[0055](2) SAP pretreatment: SAP first with 5% concentration Ca before stirring SAP (NO3)2The solution was soaked in the pretreatment of 24 h, then removed the wet after the wetting, preventing the surface excess water from gumped into the cement mortar, causing the aforemention of the mortar to change.

[0056](3) Preparation of high anti-seepage mortar: mixed with sulumate cement, quartz sand, mixed with a hydraulic epoxy resin emulsion, mixed with a curing agent, and add a defoamer, water reduction The agent was mixed with water to mix the mixture, and the mixture was mixed with the dry mixture for 1 min after 1min for 1 min, and then the pre-treatment SAP was thoroughly mixed for 2 min. After the mortar test piece, th...

Embodiment 2

[0058](1) Preparation of raw materials: 100 parts of sully aluminate cement, 300 pieces of quartz sand, 6 pieces of quartz sand, 6 parts of SAP8, waterborne epoxy, 4.3 parts of the curing agent, 30 parts of water reducer, 30 water, 30 parts of water Silicone foamed by 0.2 parts.

[0059](2) SAP pretreatment: SAP first in agitation first 8% concentration Ca (NO3)2The solution was soaked in the pretreatment of 24 h, then removed the wet after the wetting, preventing the surface excess water from gumped into the cement mortar, causing the aforemention of the mortar to change.

[0060](3) Preparation of high anti-seepage mortar: mixed with sulumate cement, quartz sand, mixed with a hydraulic epoxy resin emulsion, mixed with a curing agent, and add a defoamer, water reduction The agent was mixed with water to mix the mixture, and the mixture was mixed with the dry mixture for 1 min after 1min for 1 min, and then the pre-treatment SAP was thoroughly mixed for 2 min. After the mortar test piece,...

Embodiment 3

[0062](1) Preparation of raw materials: 100 parts of sulfur-aluminate cement, 300 pieces of quartz sand, 9 pieces of SAP13, and 6.4 parts of the curing agent, 30 parts of water reducer, 30 parts of water, 30 parts of water 0.3 parts of the silicon diffuser.

[0063](2) SAP pretreatment: SAP first use 10% concentration Ca before stirring SAP (NO3)2The solution was soaked in the pretreatment of 24 h, then removed the wet after the wetting, preventing the surface excess water from gumped into the cement mortar, causing the aforemention of the mortar to change.

[0064](3) Preparation of high anti-seepage mortar: mixed with sulumate cement, quartz sand, mixed with a hydraulic epoxy resin emulsion, mixed with a curing agent, and add a defoamer, water reduction The agent was mixed with water to mix the mixture, and the mixture was mixed with the dry mixture for 1 min after 1min for 1 min, and then the pre-treatment SAP was thoroughly mixed for 2 min. After the mortar test piece, the film was ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com