Kitchenappliance glass tempering heat treatment device and process

A heat treatment device and glass tempering technology, applied in the direction of glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problems that affect the glass heat treatment effect, and it is difficult to ensure the uniform heating of the glass, so as to ensure the glass heat treatment effect, shorten the heating time, Increase the effect of air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

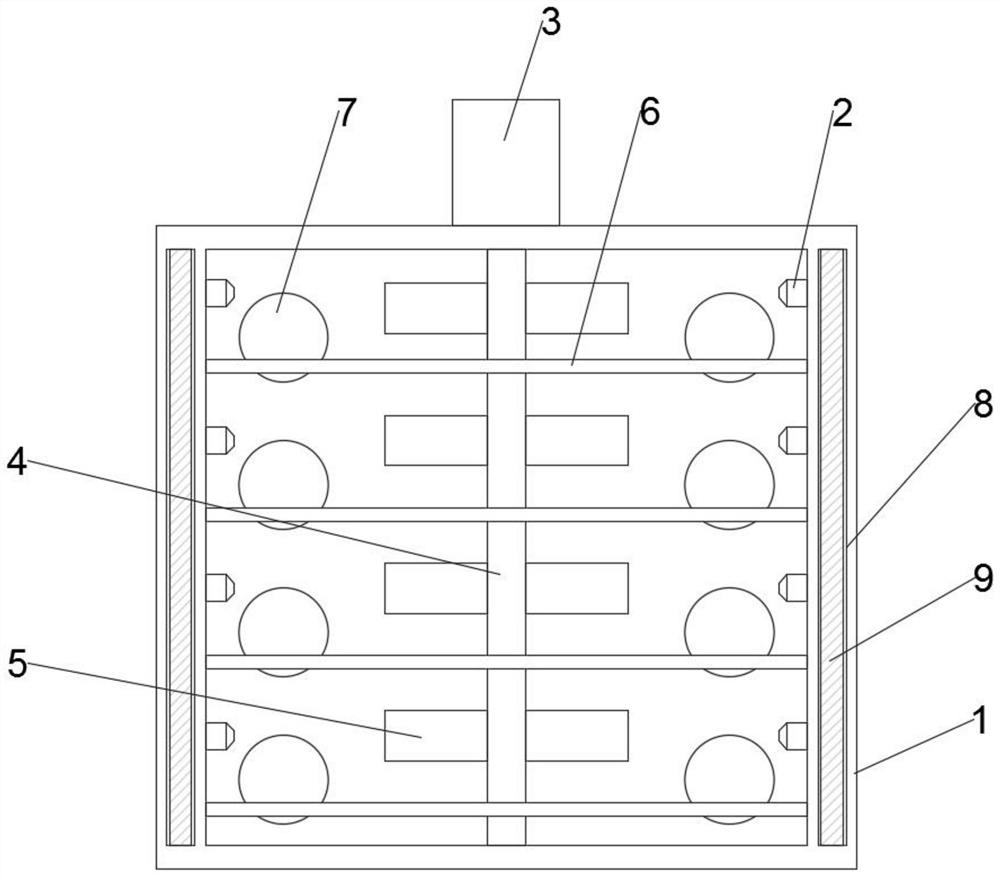

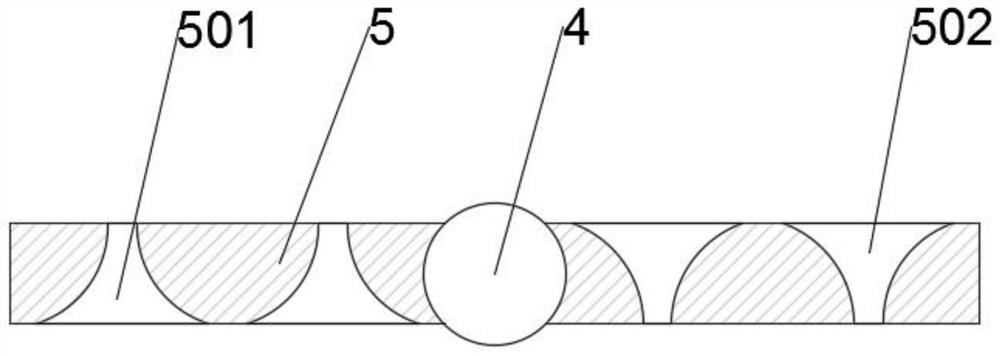

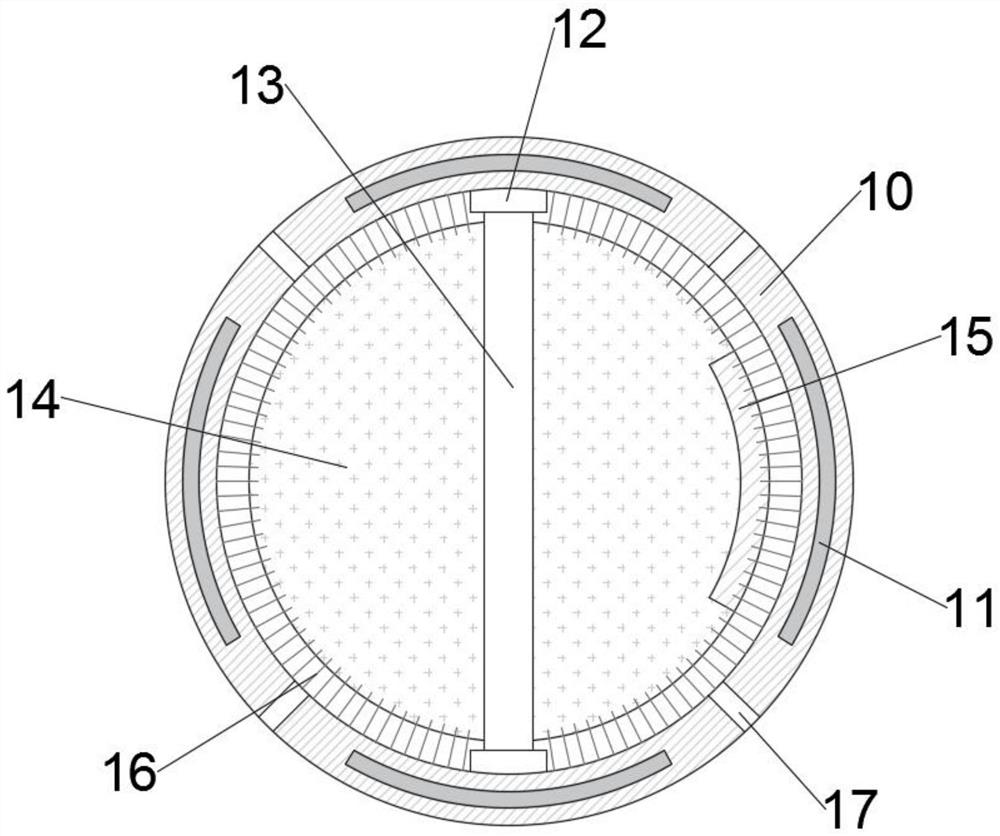

[0040] see figure 1 , a glass tempering heat treatment device for kitchen appliances, comprising a heating furnace 1, a glass heat treatment work area is arranged inside the heating furnace 1, a plurality of evenly distributed heating furnace nozzles 2 are arranged on the inner wall of the heating furnace 1, and the upper surface of the heating furnace 1 A driving motor 3 is fixed, and a rotating shaft 4 is vertically arranged at the inner center of the heating furnace 1. The top of the rotating shaft 4 runs through the upper surface of the heating furnace 1 and is connected with the output end of the driving motor 3. There are multiple shafts fixed on the outer wall of the rotating shaft 4 A group of symmetrically arranged air deflectors 5, with air guide holes provided on the air deflectors 5, the inside of the heating furnace 1 is located on both sides of the rotating shaft 4 and the air deflectors 5, and multiple groups of horizontally arranged rolling rods 6 are fixed. Tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com