Flue gas separation and purification system for producing electronic-grade sulfuric acid

An electronic-grade, sulfuric acid technology, applied in sulfur trioxide/sulfuric acid and other directions, can solve the problems of low safety, uneven distribution of cooling water inflow, inability to remove high-purity sulfur trioxide from flue gas, etc., to improve the safety of use. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

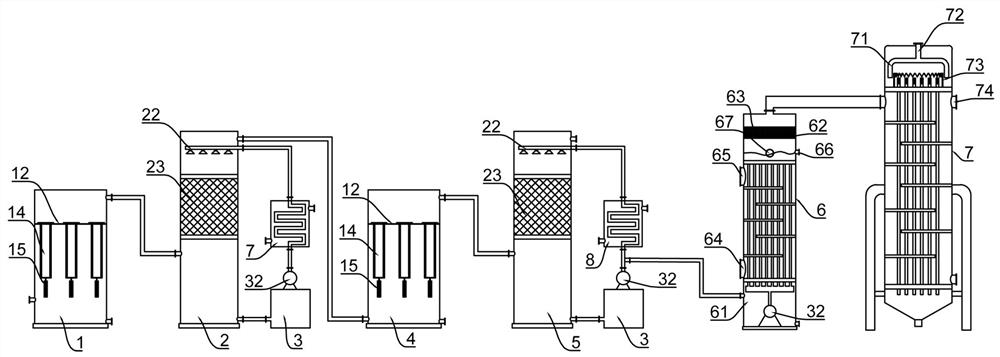

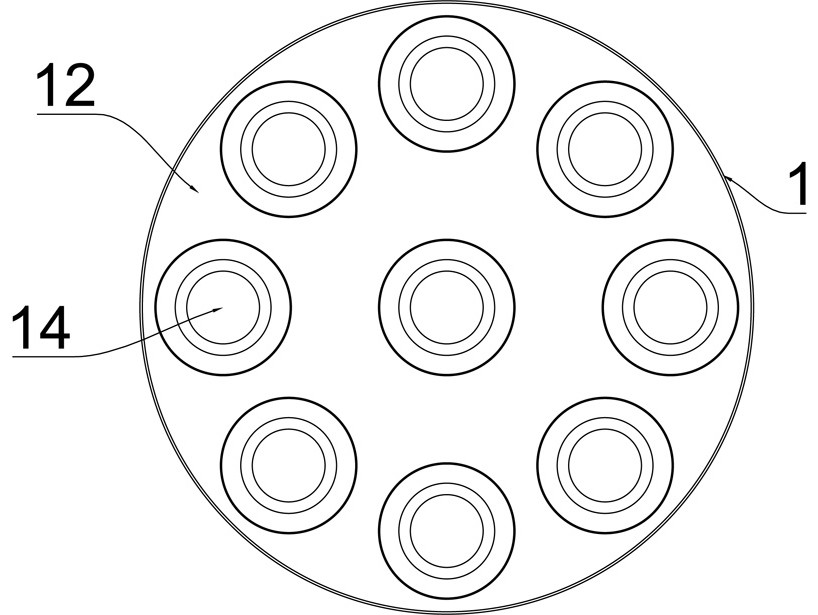

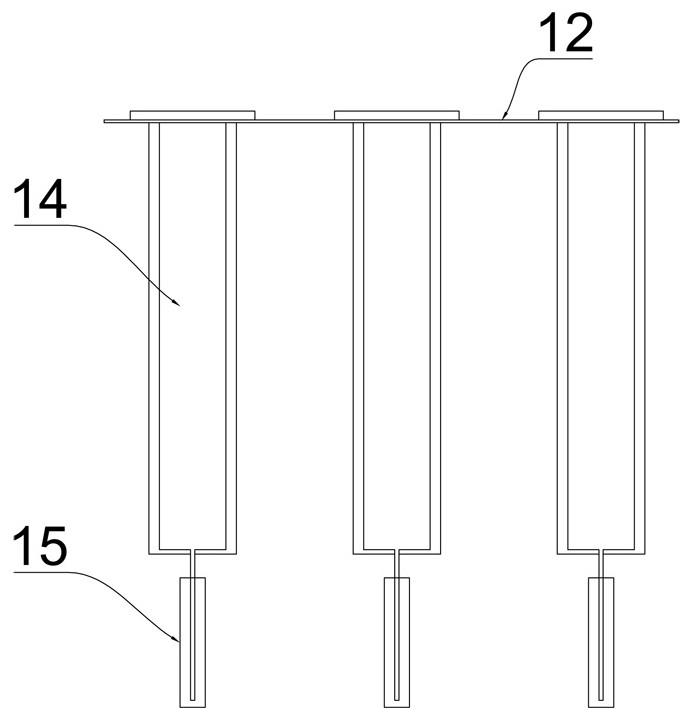

[0042]The present invention will be further described below with reference to the accompanying drawings and specific embodiments:

[0043]Such asFigure 1 ~ 10As shown, a flue gas separation and purification system for producing electronic grade sulfuric acid, including a seminated dust collector 1, a washing column 2, a peptile 4, a nicotorcin absorption tower 5, a niacin evaporation tank 6 And condensed tank 7, the scrubbing tower 2 and the niacin absorption tower 5 are also sequentially connected to the circulating groove 3 and the nicotinic acid cooler 8.

[0044]Specifically, the air outlet of the dust collector 1 is coupled to the intake port of the wash column 2 by a conduit, and the air outlet of the cleaning column 2 is connected to the intake port of the high-efficiency decelerator 4 through a pipe. The air outlet of the aerosol 4 is connected to the intake port of the niacin absorption tower 5 through the pipe, and the acid opening of the washing column 2 is connected by a pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com