EPS foam box and production method thereof

A foam box and modification technology, applied in the direction of covering/external coating, etc., can solve the problems of EPS foam box easy to drop powder and debris, etc., and achieve the effect of simple structure, improved wear resistance, and easy popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

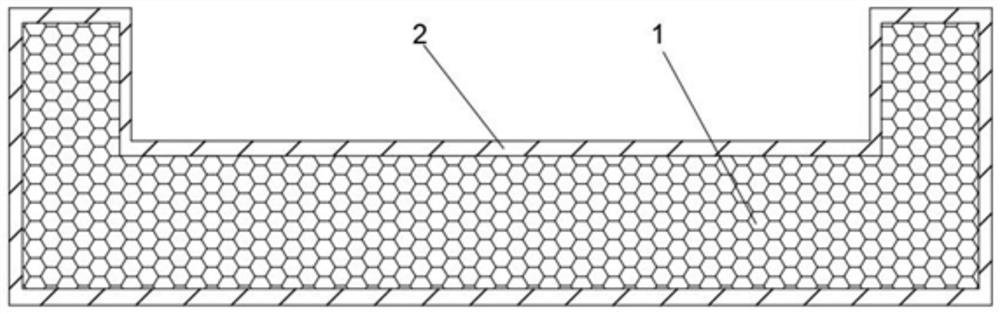

[0030]Such asfigure 1 As shown: an EPS foam box, including the foam box body 1, and a layer of reinforcing modified film 2 is provided on the surface of the foam box body 1, in particular, a layer of enhanced modified film is provided on the outer surface of the foam box body 1. .

[0031]The thickness of the enhanced modified film 2 is 10 mm.

[0032]The enhanced modified film 2 is made of a substance corresponding to the weight of mass: 25 parts of low density polyethylene, 55 serial low-density polyethylene, 2 copies of lauriene, 1 part of sodium pyrophosphate, and 4 reinforcing fillers.

[0033]The preparation method of the enhanced filler includes the following steps:

[0034]1) Blend the nano-titanium dioxide with the kaolin, the ball milling treatment is taken out after 40min, and the copper powder is spared;

[0035]2) Putting the blended powder obtained by step 1) into the composite solution, and then filtered after 1.5 h, and then flushing it with deionized water, and finally the drying ...

Embodiment 2

[0043]Such asfigure 1 As shown: an EPS foam box, including the foam box body 1, and a layer of reinforcing modified film 2 is provided on the surface of the foam box body 1, in particular, a layer of reinforced modified film 2 is provided on the inner surface of the foam box body 1. .

[0044]The thickness of the reinforced modified film is 10 mm.

[0045]The enhanced modified film is made of a substance corresponding to a weight of mass, a low density polyethylene, 57 serial low-density polyethylene, 3 copies of lauren, 2 parts of sodium pyrophosphate, and 6 reinforcing fillers.

[0046]The preparation method of the enhanced filler includes the following steps:

[0047]1) A blend of nano-titanium dioxide with the kaolin and take it out after 45 minutes of ball milling, and is blended.

[0048]2) Putting the blended powder obtained by step 1) into the composite solution, and then filtered after 2 h, continuously for 2 h, then flushing it with deionized water, and finally the drying is then process...

Embodiment 3

[0056]Such asfigure 1 As shown: an EPS foam box, including the foam box body 1, and a layer of reinforcing modified film 2 is provided on the surface of the foam box body 1, and in particular, there is a layer of enhancement on the outer surface of the foam box body 1. Modified film 2.

[0057]The thickness of the reinforced modified film is 10 mm.

[0058]The enhanced modified film is made of a corresponding mass of material: 30 copies of low density polyethylene, 60 parts of linear low density polyethylene, 4 copies of lauren, 3 servile sodium sodium phosphate, 8 reinforcing fillers.

[0059]The preparation method of the enhanced filler includes the following steps:

[0060]1) Take the nano-titanium dioxide with the kaolin, the ball mill is removed after 50min, and the blending material is spared;

[0061]2) Putting the blended powder obtained by step 1) into the composite solution, and the ultrasonic treatment is continuously filtered, and then it is flushed with deionized water, and finally th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com