Rapid fixing clamp for aluminum alloy machining

A technology for fixing fixtures and aluminum alloys, applied in metal processing, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of complex fixture structure, inability to achieve rapid clamping of aluminum alloy sheets, and complicated operation steps, and achieve a degree of automation High, improve clamping efficiency and tightening accuracy, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

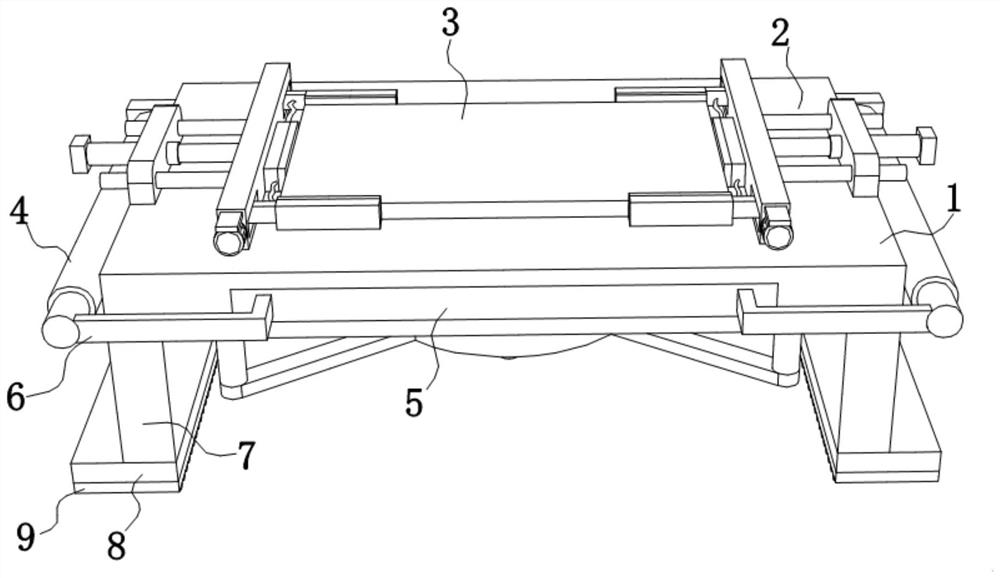

[0034] Such as Figure 1-Figure 6 As shown, the present invention provides a fast fixing fixture for aluminum alloy processing, including a fixed table 1 and an aluminum alloy plate 3, two support plates 7 are provided at the bottom of the fixed table 1, and a base 8 is provided at the bottom of the support plate 7, and the base 8 The bottom is provided with anti-slip mat 9, and the bottom of anti-slip mat 9 is provided with anti-skid pattern, and the anti-slip mat 9 that is provided with anti-slip pattern can increase the friction force between base 8 and the ground, strengthen the stability of whole device, two support plates 7 play The function of supporting the fixed platform 1, the fixed platform 1 is symmetrically provided with two clamping components 2;

[0035] The clamping assembly 2 includes a fixed plate 201, one end of the fixed plate 201 is provided with a hydraulic cylinder 205, and the output end of the hydraulic cylinder 205 passes through the fixed plate 201 t...

no. 2 example

[0040] Based on the fast fixing fixture for aluminum alloy processing provided in the first embodiment, the aluminum alloy plate 3 is clamped by means of the first clamping plate 203 and the second clamping plate 214. Due to the poor rigidity of the aluminum alloy plate 3, the resistance The plastic deformation ability is poor, and it is obviously not enough to judge the clamping degree of the aluminum alloy plate 3 based on the experience of the operator during the clamping process, and because the aluminum alloy plate 3 is in a suspended state, it is easy to cause clamping Extrusion deformation, and when using a tool to cut the aluminum alloy plate 3 in a certain direction, due to its poor rigidity, it is easy to cause processing deformation during the processing, and after the cutting is completed, the larger clamping plate Under the action of force, it may also cause the aluminum alloy plate 3 to break. In order to solve this problem and ensure that it has an excellent clam...

no. 3 example

[0043] Based on the fast fixing fixture for aluminum alloy processing provided in the second embodiment, when the aluminum alloy plate 3 is cut and processed by the suction cup 217 on the side of the first clamping plate 203 and the second clamping plate 214, due to the suction cup 217 It has a certain degree of elasticity, especially the suction cup 217 perpendicular to the cutting direction will inevitably cause the cutting surface to vibrate during cutting, the vibration of the aluminum alloy plate 3 caused by the cutting will reduce the cutting effect, and at the same time, a large amount of waste will be generated in the cutting process. Chips, with the aid of coolant flushing, the waste at the processing position flows along the coolant to the fixed table 1. If the waste cannot be removed in time, the cutting effect will be greatly reduced, resulting in uneven cutting positions of the aluminum alloy plate 3 and reduced cutting accuracy. , in order to solve this problem an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com