Thin-walled tube penetrating and conveying device

A technology for conveying devices and thin-walled pipes, which is applied in the field of thin-walled pipe-through-pipe conveying devices, which can solve problems such as simple and boring work for workers, unavoidable damage, and damage to thin-walled pipe fittings, so as to improve the working environment of workers and avoid jamming damage and avoid bending damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

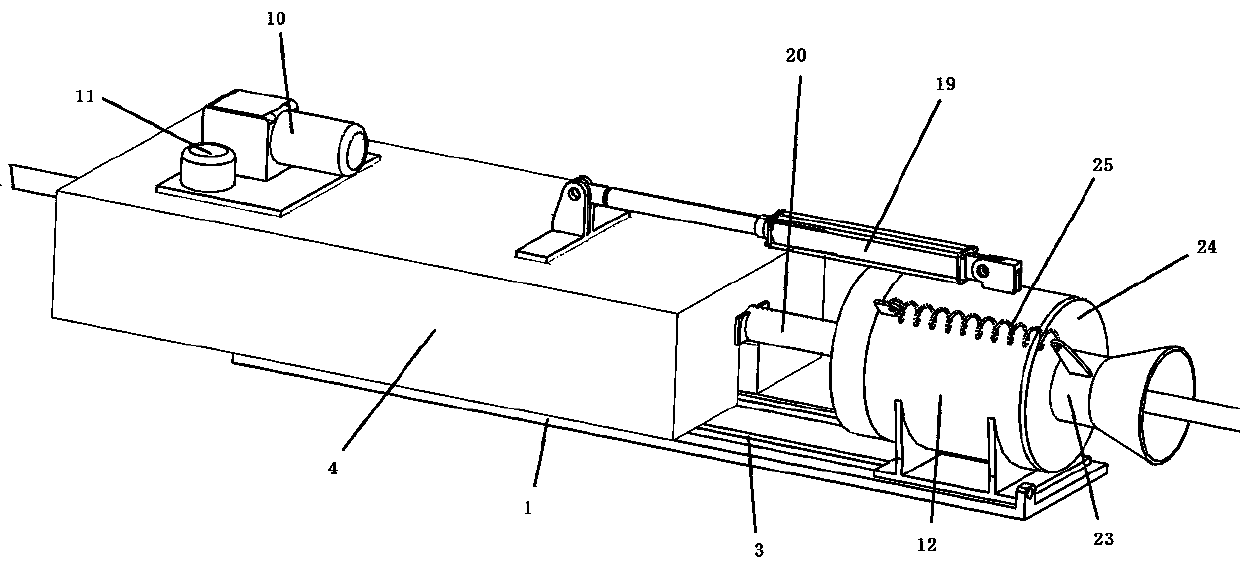

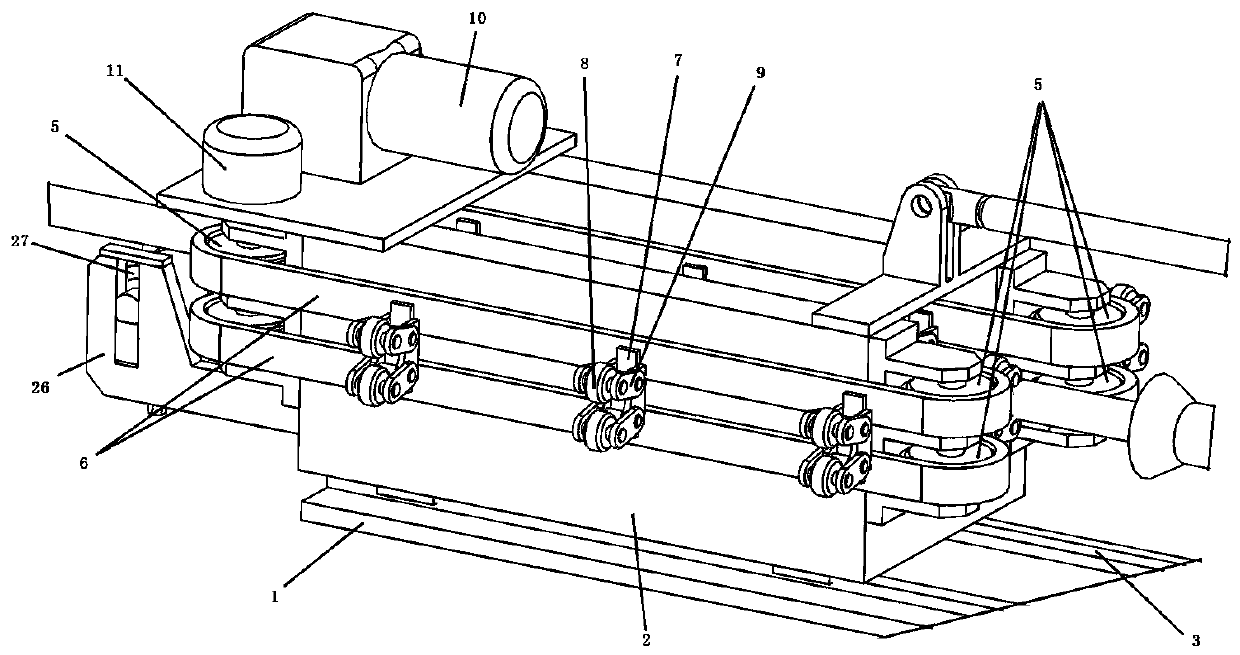

[0025] Such as Figure 1 to Figure 7 As shown, a thin-walled pipe piercing conveying device includes an installation base 1, a slide table 2 is provided on the left side above the installation base, a slide rail 3 is provided on the upper surface of the installation base 1, and the slide table 2 A slide groove is arranged on the lower bottom surface, and the slide groove is arranged on the slide rail 3, so relative sliding can occur between the installation base 1 and the slide table. A shield 4 is provided above the slide 2, and the left and right ends of the shield 4 are provided with inlets and outlets for thin-walled pipes. The slide 2 and the shield 4 are fixedly connected, that is, the slide 2 and the shield There will be no relative displacement between 4. The slide table 2 is provided with two groups of clamping and conveying mechanisms opposite to each other, and each set of clamping and conveying mechanisms includes sprockets 5 arranged at the left and right ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com