Egg yolk shell hollow ferroferric oxide@air@carbon nano composite wave-absorbing material and preparation method thereof

A technology of ferroferric oxide and carbon nanocomposite, applied in shielding materials, electrical components, magnetic field/electric field shielding, etc., can solve problems affecting the normal operation of the immune system, secret electromagnetic signal leakage, human health hazards, etc., and achieve easy regulation The effect of microwave absorption performance, low filling ratio, and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036](1) Weigh 3.2436 g of sodium citrate, 7.0584 g of sodium citrate and 2.1624 g of urea, sequentially dissolved in 210 mL deionized water, then add 1.8 g of polyacrylamide, stir the solution at room temperature 5 h to uniform Clarified, the rear polytetrafluoroethylene liner washed 10 h at 200 ° C at 200 ° C, and the resulting black mud product was washed 5 times with deionized water, and no water ethanol washing 3 times, drying at 60 ° C, that is, the hollow tetoxide Iron nanoparticles;

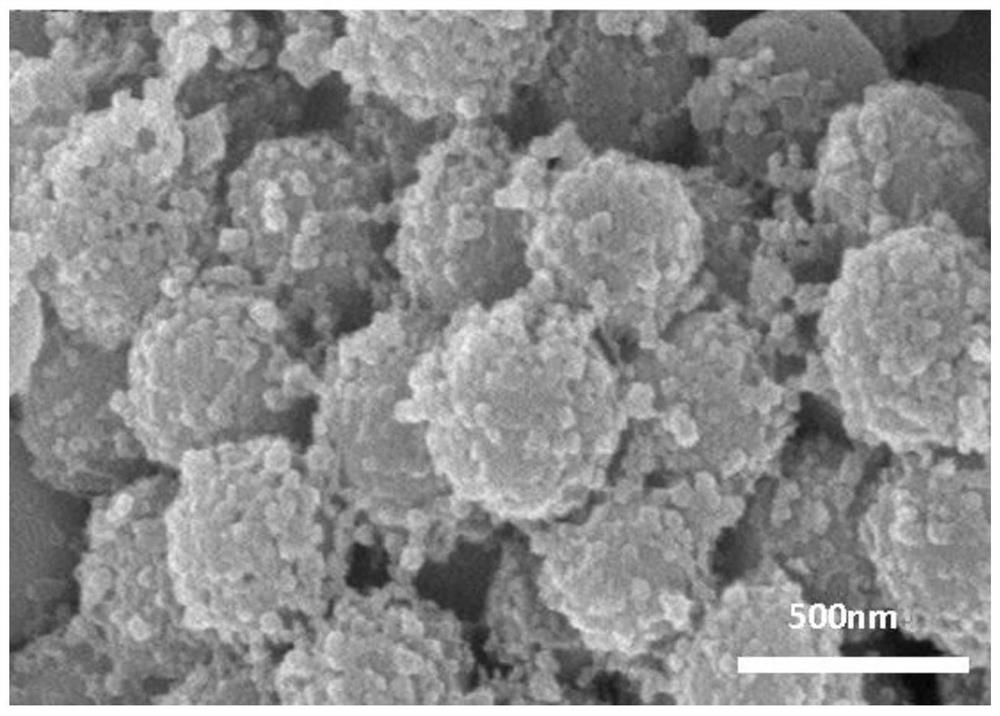

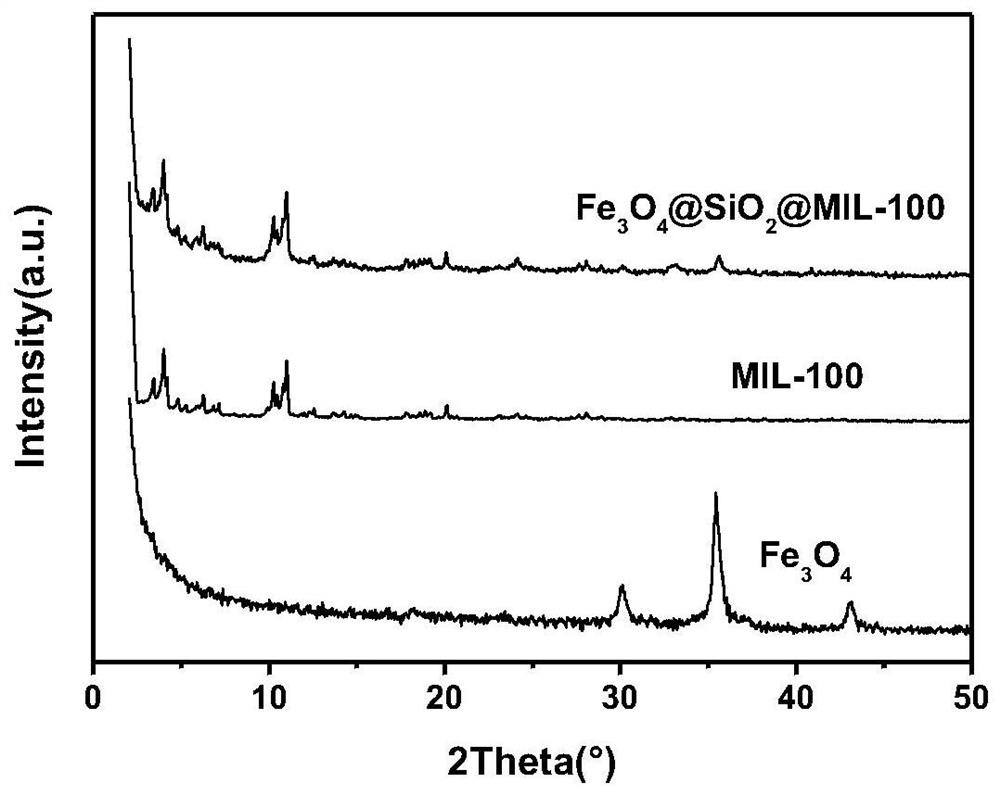

[0037](2) Weighing 300 mg of hollow tetrashydriobiobiometers dispersed in 150 ml of ethanol, 50 ml deionized water mixed solution, ultrasonic dispersion of 30 min, adding 4 mL of concentrated ammonia water (concentration of 25 wt / %), mechanical stirring 5 MIN, 1 mL of TEOS (tetraeth ester) was added, and once again, it was added once, a total of 3 times, mechanically stirred 6 h, the resulting product was washed 5 times with ethanol, 60 ° C drying, FE3O4@Sio2Nanoparticles;

[0038](3) Weigh 100 mg ...

Embodiment 2

[0046]Example 2 The difference from Embodiment 1 is that in step (5), the calcination temperature is 700 ° C, and the remaining process conditions are identical, and the black product made by the example is Named P-700.

[0047]The egg yolk hydroforming three iron @ air @ carbon nano-composite absorbing material (P-700) is mixed with paraffin, and the ratio of paraffin is 7.00 mm in the special mold. The inner diameter is 3.04 mm, the thickness of about 2 mm is 30%, and the product mass fraction is 30%, and the electromagnetic parameters are tested using the N5224A vector network analyzer, calculated to obtain the absorbing performance, and the test frequency range is 2-18 GHz.

[0048]The reflection loss of the sample P-700 follows the frequency change curve such asFigure 4As shown, when the thickness of the coating is 3 mm, the maximum absorption intensity of the composite can reach -27.7 dB; when the thickness of the coating is 2 mm, the effective absorption band is as high as 8 GHz, w...

Embodiment 3

[0050]Example 3 The difference from Embodiment 1 is that in step (5), the calcination temperature is 800 ° C, and the remaining process conditions are identical, and the black product made by this embodiment is named P-800.

[0051]The egg yolk housing hollow tetraned iron @ air @ carbon nanocomposite absorbing material (P-800) is mixed with paraffin, and the ratio of paraffin is 70% by 70% by weight, and it is pressed into an outer diameter of 7.00 mm in a special mold. The inner diameter is 3.04 mm, the thickness of about 2 mm is 30%, and the product mass fraction is 30%, and the electromagnetic parameters are tested using the N5224A vector network analyzer, calculated to obtain the absorbing performance, and the test frequency range is 2-18 GHz.

[0052]When the coating has a thickness of 5.5 mm, the egg yolk housing hollow tetraned iron @ air @ carbon nanocomposite absorbing material can be up to -25 dB, and the effective absorption bandwidth is 2 GHz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com