Perovskite transparent photovoltaic glass and preparation method thereof

A technology of photovoltaic glass and transparent conductive glass, which is applied in photovoltaic power generation, semiconductor/solid-state device manufacturing, and sustainable buildings, and can solve problems such as unevenness, poor battery performance, and low film thickness of the absorbing layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

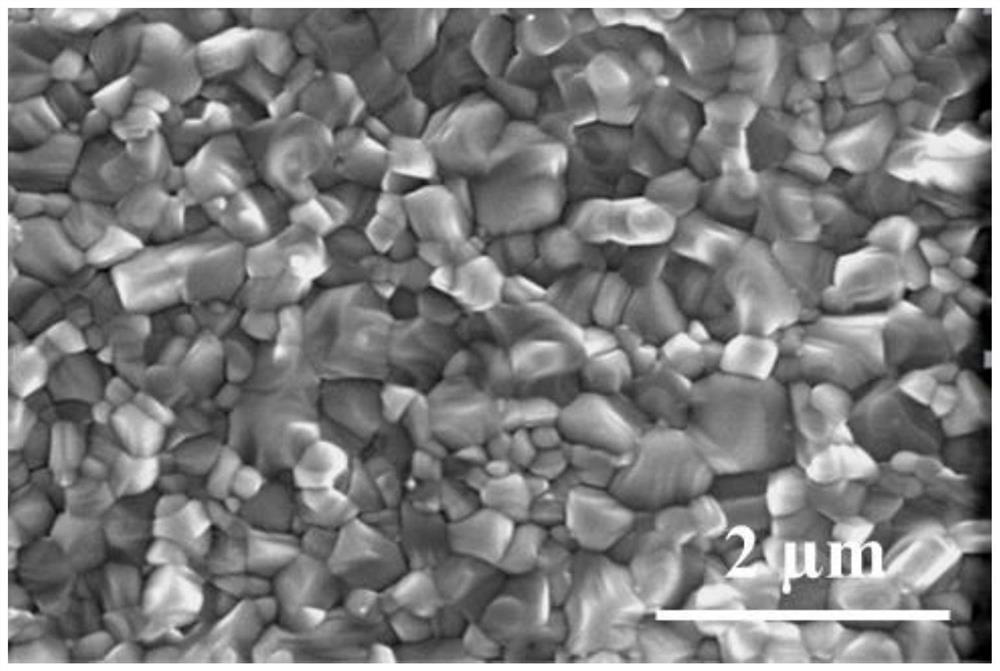

[0045] The preparation method of the perovskite layer uses a two-step method.

[0046] The hole transport layer is 2,2',7,7'-tetrakis[N,N-bis(4-methoxyphenyl)amino]-9,9'-spirobifluorene spiro-OMeTAD, poly[ Bis(4-phenyl)(2,4,6-trimethylphenyl)amine]PTAA, carbon nanotube CNT, cuprous thiocyanate CuSCN or poly 3-hexylthiophene P3HT, etc.

[0047] The transparent electrode is a metal oxide / conductive metal / metal oxide sandwich electrode or a transparent conductive oxide electrode.

[0048] The metal oxides include MoO 3 , V 2 o 5 、WO 3 and other transition metal oxides.

[0049] The conductive metal includes Au, Ag, Cu and the like.

[0050] When the battery structure is p-i-n type, the transparent conductive glass is a transparent conductive glass substrate such as indium tin oxide ITO, fluorine-doped tin oxide FTO, or the like.

[0051] The hole transport layer is poly 3,4-ethylenedioxythiophene / polystyrene sulfonate PEDOT:PSS, poly[bis(4-phenyl)(2,4,6-trimethylphenyl)ami...

Embodiment 1

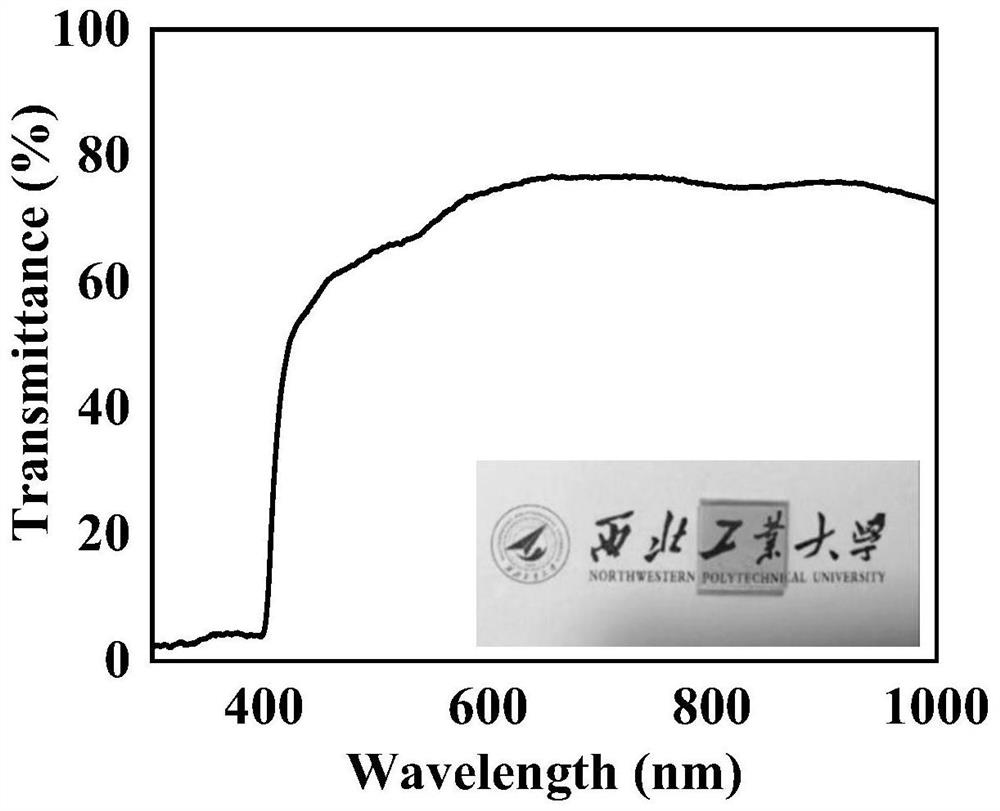

[0061] The structure of an n-i-p type photovoltaic glass is a conductive glass, a dense electron transport layer, a wide bandgap perovskite light-absorbing layer, a hole transport layer, and a transparent electrode from bottom to top.

[0062] The preparation method is as follows:

[0063] (1) After ultrasonically cleaning conductive glass such as ITO or FTO, prepare TiO by spin coating, spray coating, and chemical bath deposition 2 , SnO 2 , ZnO and other dense electron transport layers, the thickness is about 30-50nm.

[0064] (2) PbX 2 Dissolve in dimethyl sulfoxide or N,N-dimethylformamide to prepare a lead halide solution, heat and stir at 50°C-70°C to dissolve, take 40-80μL lead halide solution and deposit it on a transparent surface coated with a dense electron transport layer Conductive glass surface, spin dry.

[0065] (3) After it cools naturally, place it in CH 3 NH 3 Cl, CH 3 NH 3 Br or HC(=NH)NH 2 Cl, HC(=NH)NH 2 React in the alcohol solution of Br for 1...

Embodiment 2

[0073] The structure of a p-i-n type photovoltaic glass is a conductive glass, a hole transport layer, a wide bandgap perovskite light-absorbing layer, an electron transport layer, and a transparent electrode from bottom to top.

[0074] The preparation method is as follows:

[0075] (1) After ultrasonically cleaning conductive glass such as ITO or FTO, prepare PEDOT:PSS, NiO by spin coating method x Or a hole transport layer such as PTAA.

[0076] (2) PbX 2 Dissolve in dimethyl sulfoxide or N,N-dimethylformamide to prepare a lead halide solution, heat and stir at 50°C-70°C to dissolve, take 40-80μL lead halide solution and deposit it on the transparent surface coated with the hole transport layer Conductive glass surface, spin dry.

[0077] (3) After it cools naturally, place it in CH 3 NH 3 Cl, CH 3 NH 3 Br or HC(=NH)NH 2 Cl, HC(=NH)NH 2 React in the alcohol solution of Br for 10-30 minutes, rinse with ethanol, isopropanol and other alcohol solvents after the reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com