Preparation method of molybdenum-based composite material electrode plate

A composite material and electrode plate technology, applied in electrodes, electrode coatings, electrolysis processes, etc., can solve the problems of restricting the industrialization process of water splitting and hydrogen production, high cost, etc., and achieve broad large-scale industrial production prospects, strong applicability, and improved The effect of catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

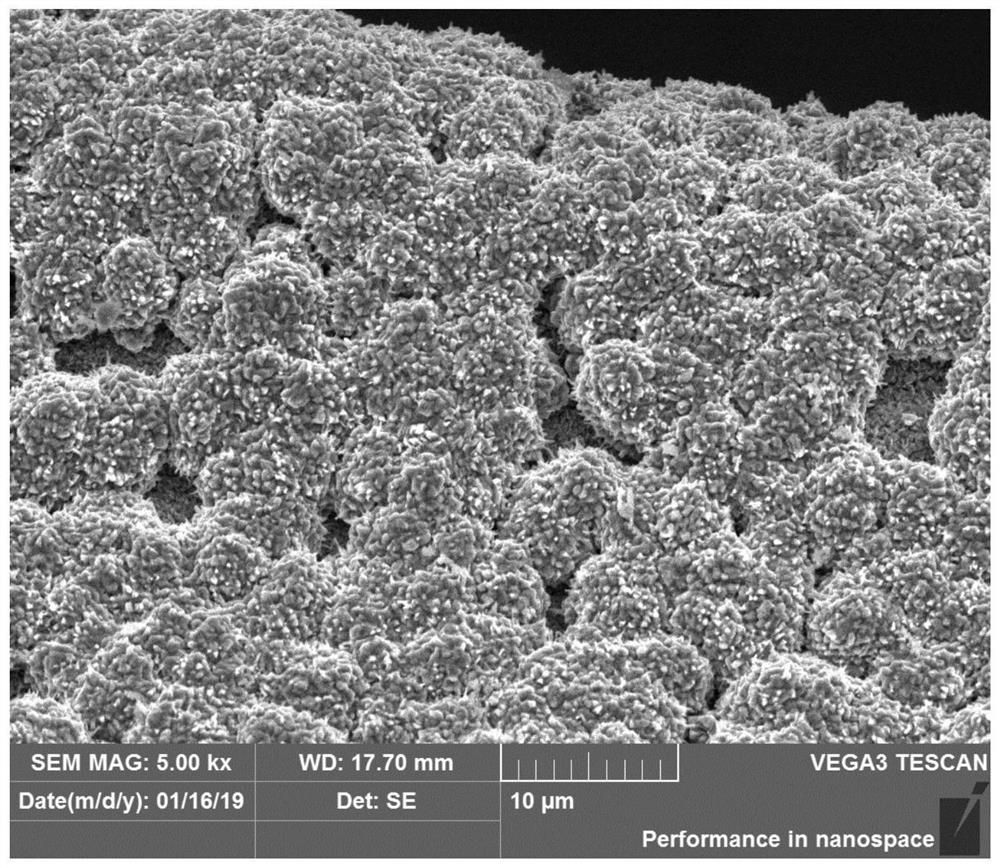

[0029] A method for preparing a molybdenum-based composite material electrode plate mainly includes the following steps:

[0030] Step 1. According to the demand size of the final electrode product, weigh a certain amount of molybdenum powder and nickel powder, and select a suitable graphite mold for future use.

[0031] For example, according to the size of the final product, determine the volume and shape parameters, so as to select the appropriate size graphite mold, and estimate the quality of the required powder by the product of volume and density. Here, the mass ratio of molybdenum powder to nickel powder is (3-10):1. The molybdenum powder is the main body of the electrode material of the present invention, and the nickel powder plays the role of assisting sintering and preparing the porous matrix material.

[0032] Step 2. In a glove box filled with argon, take excess titanium tetrachloride liquid and place it in a beaker, and slowly pour the mixed powder in step 1 in...

Embodiment 1

[0047] (1) Weigh 3g of molybdenum powder and 1g of nickel powder, select a graphite mold with a diameter of φ20, and set aside.

[0048] (2) In a glove box filled with argon, take excess titanium tetrachloride liquid and place it in a beaker, and slowly pour the mixed powder in step (1) into the beaker, and stir thoroughly.

[0049] (3) In a glove box full of argon, filter the mixed system in the beaker of step (2), leave the mixed metal powder covered with titanium tetrachloride, place the mixed metal powder in a quartz crucible, And the quartz crucible is preserved in the airtight container as a whole, and then the airtight container with the quartz crucible is taken out from the glove box;

[0050] (4) take out the quartz crucible in step (3) from the airtight container and put it into the quartz tube of the tube furnace quickly, feed oxygen, the oxygen flow rate is 30 sccm, take out the quartz crucible after the oxidation reaction finishes and collect in the quartz crucibl...

Embodiment 2

[0056] (1) Weigh 5g of molybdenum powder and 1g of nickel powder, select a graphite mold with a diameter of φ30, and set aside.

[0057] (2) In a glove box filled with argon, take excess titanium tetrachloride liquid and place it in a beaker, and slowly pour the mixed powder in step (1) into the beaker, and stir thoroughly.

[0058] (3) In a glove box full of argon, filter the mixed system in the beaker of step (2), leave the mixed metal powder covered with titanium tetrachloride, place the mixed powder in a quartz crucible, and Preserve the quartz crucible as a whole in an airtight container, and then take out the airtight container with the quartz crucible from the glove box;

[0059] (4) the quartz crucible in the step (3) is taken out from the airtight container and put into the quartz tube of the tube furnace rapidly, feeds oxygen, and the oxygen flow rate is 100 sccm, after the oxidation reaction finishes, take out the quartz crucible and collect in the quartz crucible ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com