Novel purification process of hydrogen peroxide

A new technology of hydrogen peroxide, applied in multi-stage water treatment, peroxide/peroxyhydrate/peroxyacid/superoxide/ozone, water/sewage treatment, etc., can solve the safety of hydrogen peroxide products , less economical processes, etc., to achieve the effects of reaction stability and low pyrolysis risk, high ion exchange efficiency, and guaranteeing process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

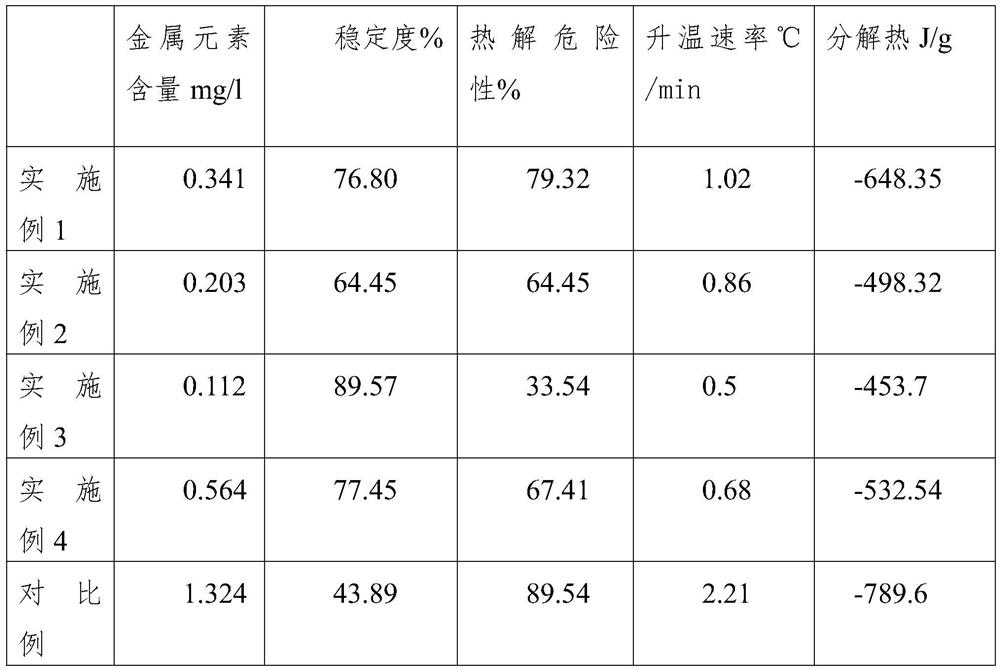

Examples

Embodiment 1

[0023] The invention provides a novel purification process for hydrogen peroxide, which specifically comprises the following steps,

[0024] Step 1: Adsorption process: put 30% industrial-grade hydrogen peroxide solution into the adsorption tank, and add a certain amount of adsorbent to the adsorption tank, and select organic component-loaded carbon chelation composed of activated alumina particles, activated carbon, etc. The adsorbent, at a temperature of 20°C, adsorbs 2H, and then removes the adsorbent through ultrafiltration, using a hollow fiber filter membrane with an outer diameter of 0.5mm and an inner diameter of 1.4mm;

[0025] Step 2: Separation and purification process: the filtrate obtained in step 1 is separated from the high-purity permeate flow and then transported to the separation tank, and separated by reverse osmosis membrane separation equipment, and the separated high-purity permeate flow is set as one or more ion exchange resin systems Resin towers formed...

Embodiment 2

[0029] A novel purification process for hydrogen peroxide, specifically comprising the following steps,

[0030] Step 1: Adsorption process: put 30% industrial-grade hydrogen peroxide solution into the adsorption tank, and add a certain amount of adsorbent to the adsorption tank. The adsorbent is organic component-loaded carbon composed of activated alumina particles, activated carbon, etc. The chelating adsorbent absorbs 2H at a temperature of 20°C, and then removes the adsorbent through ultrafiltration, using a PVDF ultrafiltration membrane with an outer diameter of 0.75mm and an inner diameter of 0.025mm;

[0031] Step 2: Separation and purification process: the filtrate obtained in step 1 is separated from the high-purity permeate flow and then transported to the separation tank, and separated by reverse osmosis membrane separation equipment, and the separated high-purity permeate flow is set as one or more ion exchange resin systems Resin towers connected in series, the f...

Embodiment 3

[0035] A novel purification process for hydrogen peroxide, specifically comprising the following steps,

[0036] Step 1: Adsorption process: put 50% industrial-grade hydrogen peroxide solution into the adsorption tank, and add a certain amount of adsorbent to the adsorption tank. The adsorbent is organic component-loaded carbon composed of activated alumina particles, activated carbon, etc. The chelating adsorbent absorbs 4H at a temperature of 30°C, and then removes the adsorbent through ultrafiltration, using a hollow fiber filter membrane with an outer diameter of 0.5mm and an inner diameter of 1.4mm;

[0037]Step 2: Separation and purification process: the filtrate obtained in step 1 is separated from the high-purity permeate flow and then transported to the separation tank, and separated by reverse osmosis membrane separation equipment, and the separated high-purity permeate flow is set as one or more ion exchange resin systems Resin towers formed in series, the filling v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com