Processing method and processing device of glass substrate

A glass substrate and processing method technology, which is applied to stone processing tools, grinding devices, stone processing equipment, etc., can solve the problem of low yield rate of glass substrates, and achieve the effects of reducing cleaning difficulty, improving yield, and reducing dust particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present disclosure will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present disclosure, and are not intended to limit the present disclosure.

[0022] In the present disclosure, the terms "first and second" are used to distinguish one element from another without any contrary description, and do not have sequence or importance. In addition, when the following description refers to the drawings, the same reference numerals in different drawings represent the same or similar elements, and the present disclosure will not repeat them here.

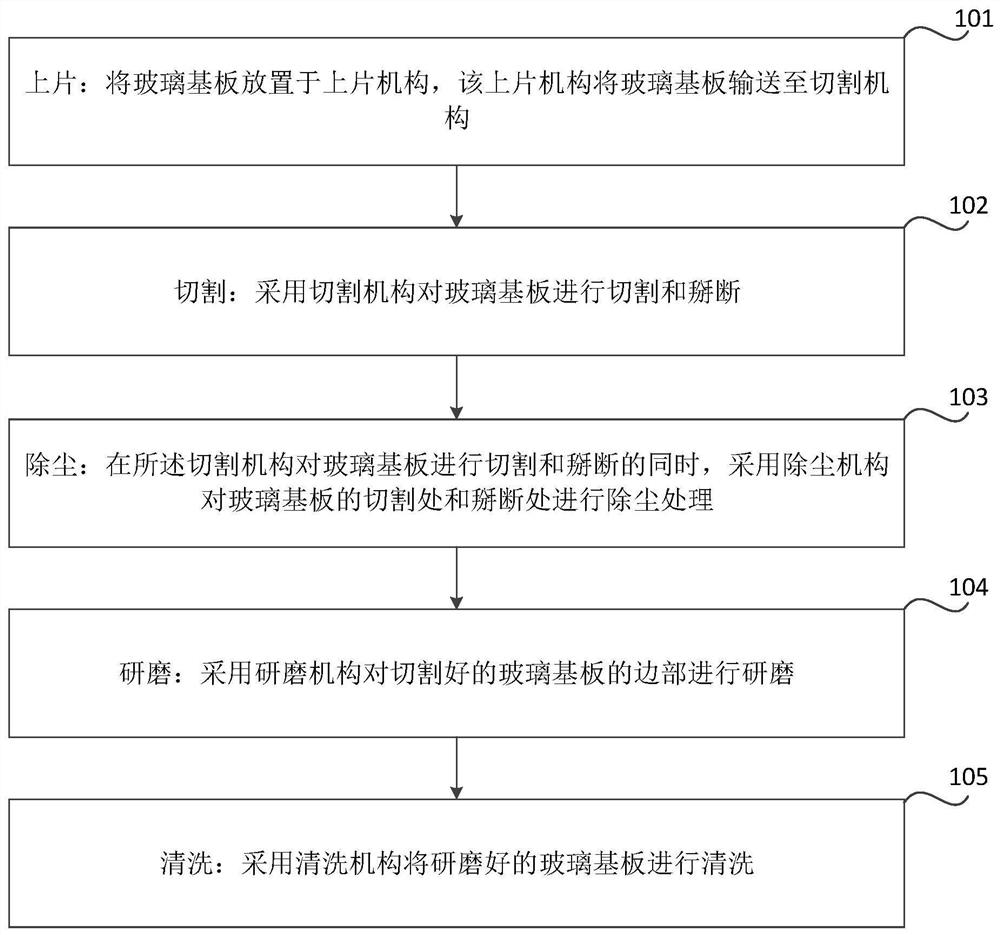

[0023] According to a specific embodiment of the present disclosure, a method for processing a glass substrate is provided, referring to figure 1 and figure 2 As shown in , the processing method includes the following steps: loading: placing the glass substrate 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com