Curved slender hole reflection inclined surface machining device

A technology of processing device and elongated hole, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of immature processing technology, blank of high-precision curved elongated hole and high-precision manufacturing field, and high processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

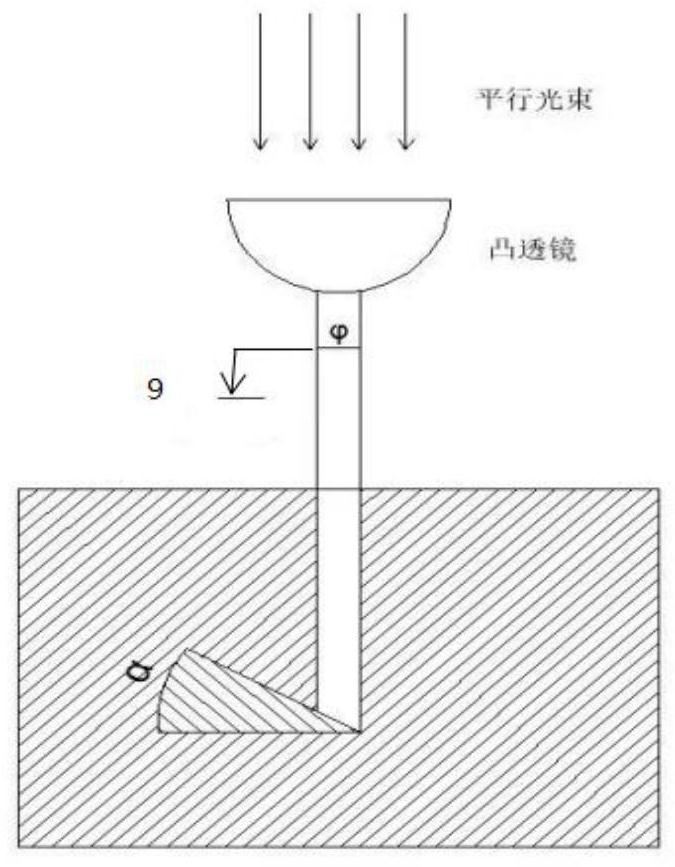

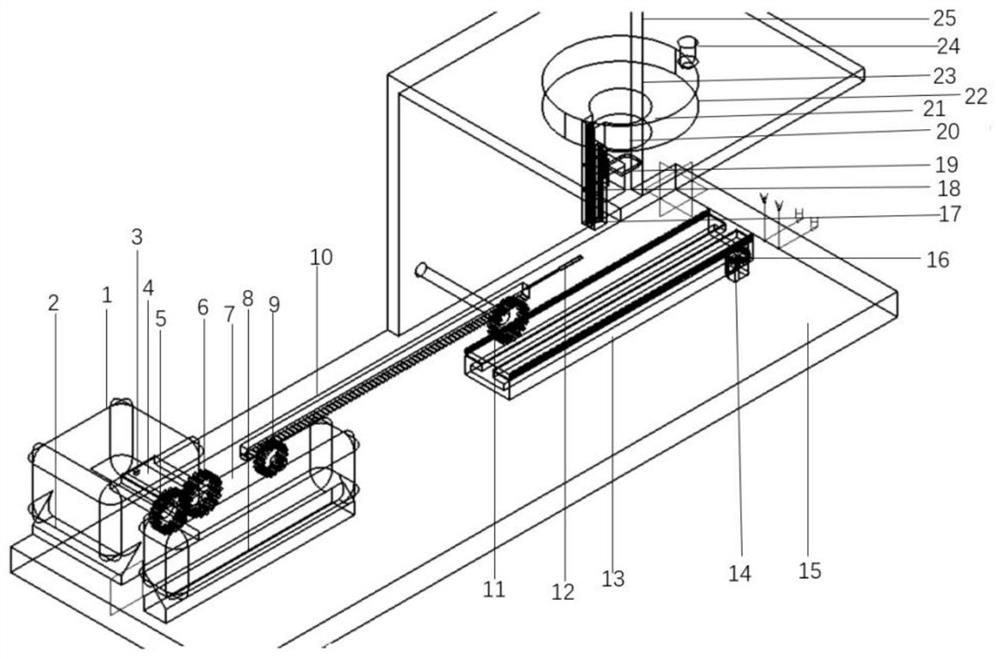

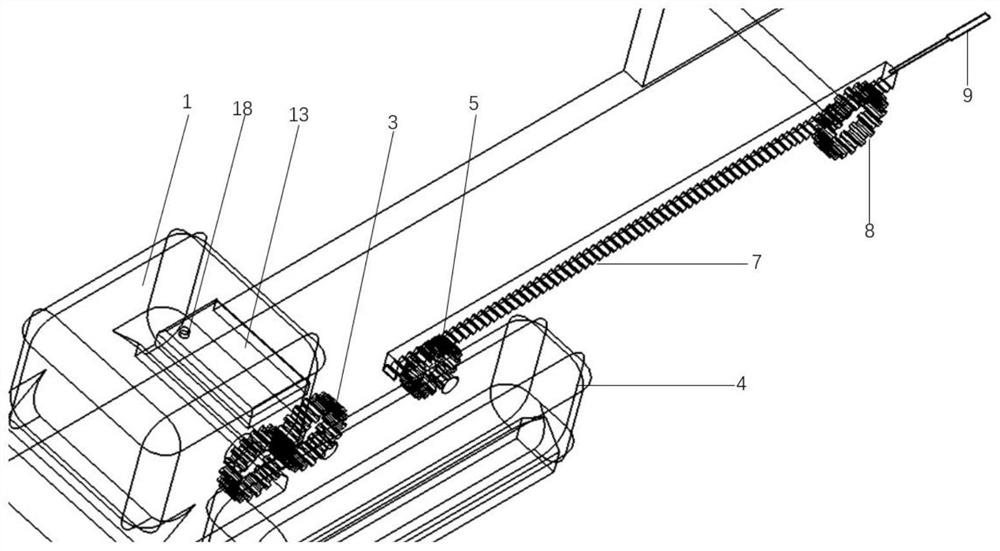

[0029] refer to figure 2 , image 3 , Figure 4 , Figure 5 , a curved slender hole reflective slope processing device, including a workbench 15, a visor driving motor 1 is installed at one end of the workbench 15, the visor driving motor 1 is located on the motor base 2, and the side of the visor driving motor 1 is installed There is a visor driving motor controller 3 with a signal to control the visor driving motor 1, a driving motor output gear 5 is arranged on the power output shaft of the visor driving motor 1, and a reducer on the input shaft of the driving motor output gear 5 and the reduction box 7 The input gear 6 is meshed for transmission, the reduction box 7 is located on the bottom 8 of the reduction box, the output gear 9 of the reduction box is meshed with the left end of the sunshade rack 10, and the right end of the sunshade ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com