Method for preparing functional coating for promoting bone repair and regeneration on degradable metal surface

A metal surface, metal base technology, applied in the direction of metal material coating process, coating, tissue regeneration, etc., can solve the problem of insufficient ability of the coating to promote bone repair and regeneration, to promote osseointegration and angiogenesis, promote blood vessels The effect of generating, promoting proliferative adhesion and migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

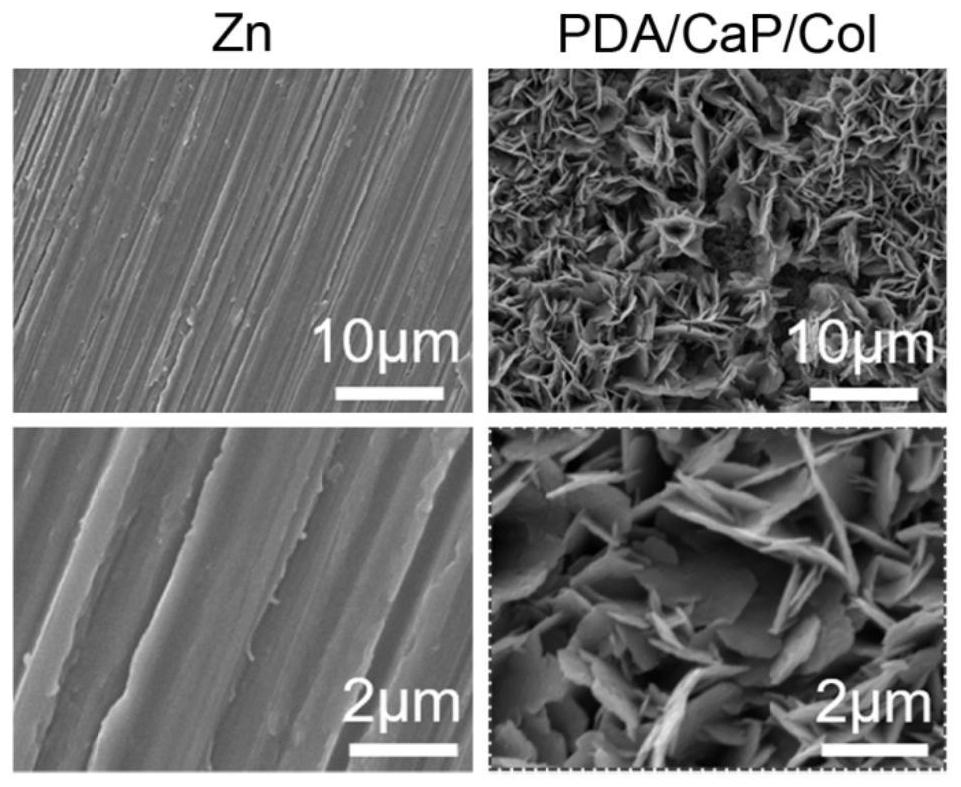

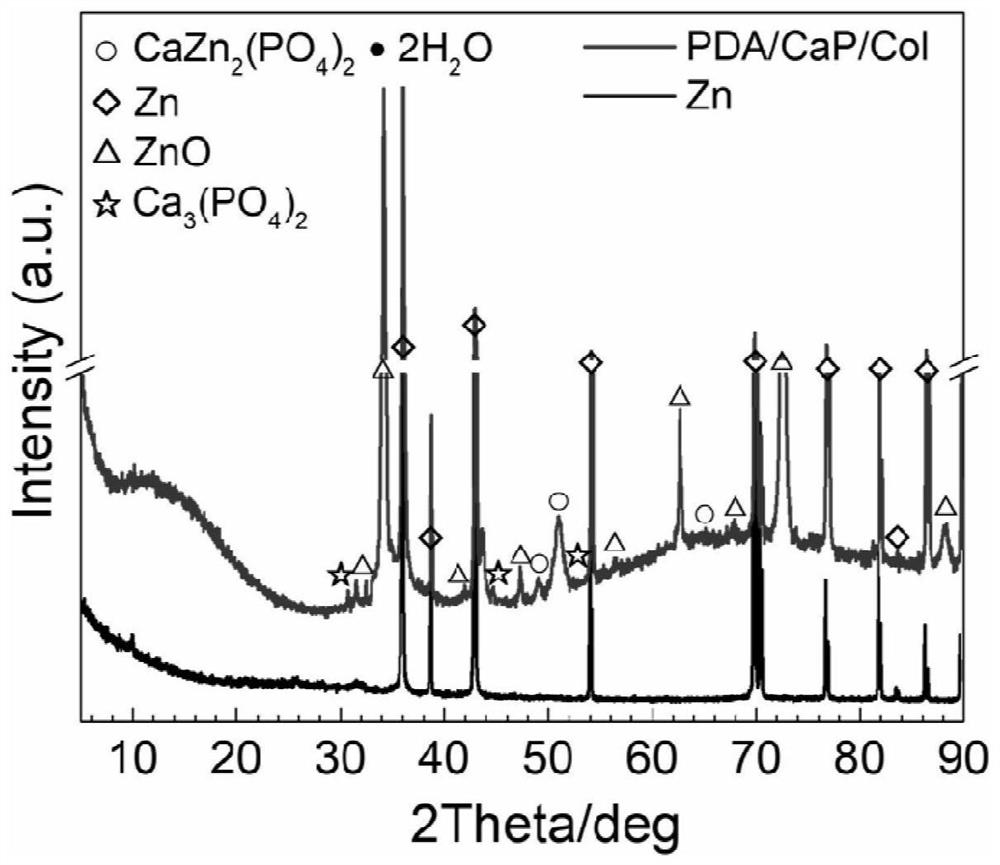

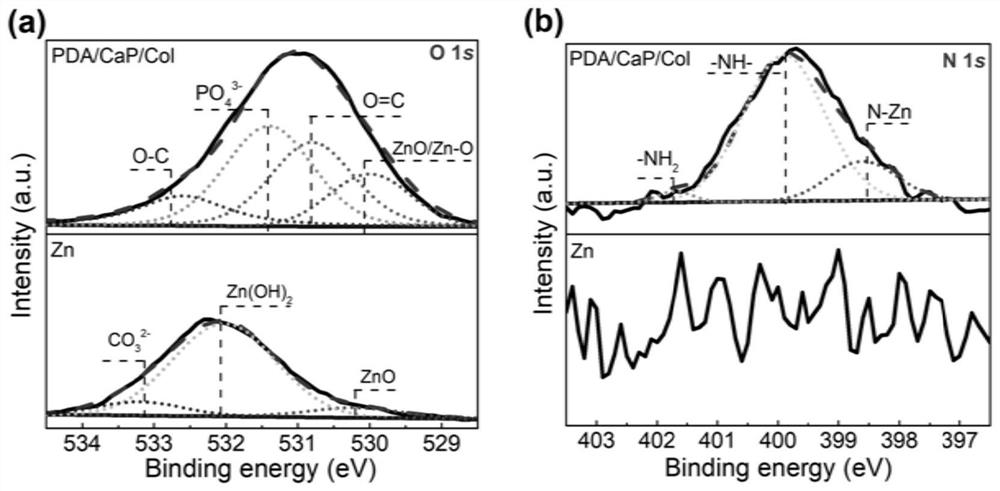

[0041] A preferred embodiment of the present invention provides a method for preparing a bone-promoting repair and regeneration coating on the surface of degradable zinc metal, the specific steps are as follows:

[0042] a. Grind metal zinc to 2000# with water abrasive paper; use deionized water and absolute ethanol to clean under ultrasonic conditions for 3 times, each time for 3 minutes, and dry it for later use;

[0043] b. Submerging the metal zinc-based layer obtained in step a in a mixed solution of 0.05M zinc nitrate solution and 0.5M sodium hydroxide solution for 2 hours at 70°C to obtain a zinc oxide layer;

[0044] c. Soak the zinc oxide layer obtained in step b in a dopamine solution with a concentration of 2 mg / ml for 6 hours at room temperature and avoid light, then wash and dry, and repeat this step 3 times;

[0045] d. Place the sample obtained in step c at room temperature in a mixture of 5 mM phosphoric acid in PBS buffer, 0.2 mg / mL type I collagen and 200 mM ...

Embodiment 2

[0047] A preferred embodiment of the present invention provides a method for preparing a bone-promoting repair and regeneration coating on the surface of degradable zinc metal, the specific steps are as follows:

[0048] a. Grind metal zinc to 2000# with water abrasive paper; use deionized water and absolute ethanol to clean under ultrasonic conditions for 4 times, each time for 3 minutes and dry for later use;

[0049] b. Submerge the metal zinc-based layer obtained in step a in a mixed solution of 0.04M zinc nitrate solution and 0.6M sodium hydroxide solution for 2 hours at 70°C to obtain a zinc oxide layer;

[0050] c. Soak the zinc oxide layer obtained in step b in a dopamine solution with a concentration of 2.5 mg / ml for 7 hours at room temperature and avoid light, then wash and dry, and repeat this step 3 times;

[0051] d. Place the sample obtained in step c at room temperature in a mixture of 4 mM phosphoric acid in PBS buffer, 0.08 mg / mL type I collagen and 220 mM calci...

Embodiment 3

[0053] A preferred embodiment of the present invention provides a method for preparing a coating for promoting bone repair and regeneration on the surface of degradable magnesium metal. The specific steps are as follows:

[0054] a. Metal magnesium is polished to 2000# with water abrasive paper; use deionized water and absolute ethanol to clean under ultrasonic conditions for 3 times, each time for 3 minutes and dry for later use;

[0055] b. Submerging the metal magnesium-based layer obtained in step a in a mixed solution of 0.06M zinc nitrate solution and 0.5M sodium hydroxide solution for 3 hours at 70°C to obtain a zinc oxide layer;

[0056] c. Soak the zinc oxide layer obtained in step b in a dopamine solution with a concentration of 1.5 mg / ml for 7 hours at room temperature and avoid light, then wash and dry, and repeat this step 3 times;

[0057] d. Place the sample obtained in step c at room temperature in a mixture of 6 mM phosphoric acid in PBS buffer, 0.12 mg / mL typ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com