Method for enhancing adhesive property of geopolymer composite material and reinforcing steel bar

A technology of geopolymers and composite materials, applied in the direction of analytical materials, preparation of test samples, and measuring devices, etc., can solve problems such as cumbersome modeling process, large amount of calculation, and complex bond-slip relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

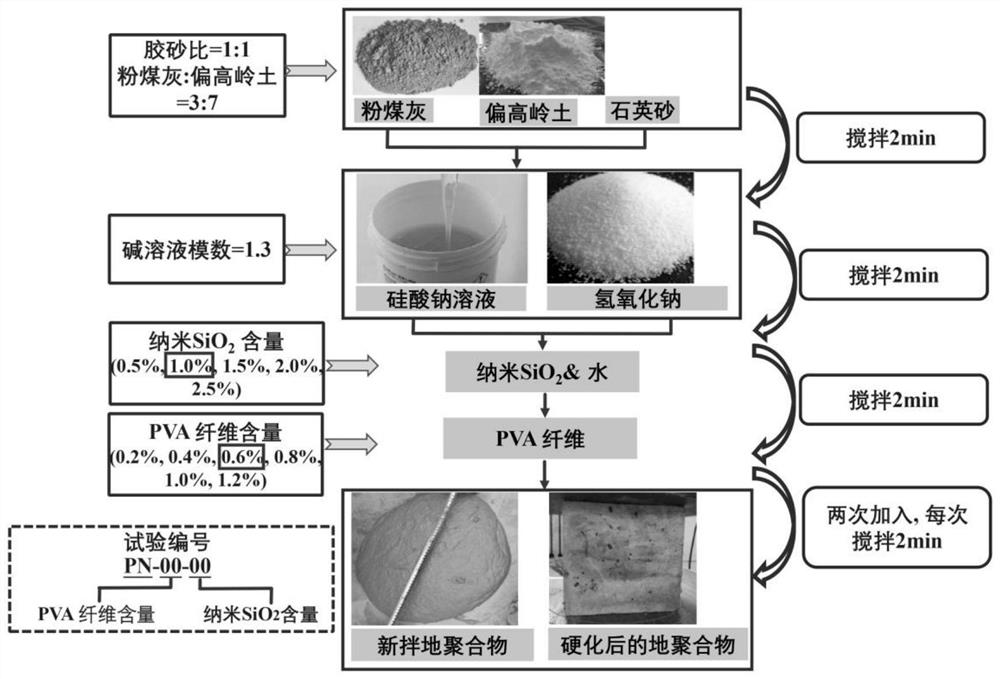

[0053] The invention provides a method for enhancing the bonding performance of a geopolymer composite material and a steel bar, and the specific steps are as follows:

[0054] Step 1. Preparation of Geopolymer Composite Materials

[0055] Raw materials for the preparation of geopolymer composites include: metakaolin, fly ash, sodium silicate solution, quartz sand (with a particle size of 75-120 μm), PVA fibers and nano-SiO 2 .

[0056] Among them, the chemical composition of metakaolin and fly ash is shown in Table 1:

[0057] Table 1

[0058]

[0059] The base activator solution consists of sodium hydroxide NaOH, sodium silicate solution and water. The sodium silicate solution has an initial modulus of 3.2 and a concentration of 40%. Add NaOH to the sodium silicate solution to adjust its modulus from 3.2 to 1.3, and then continue to add water to adjust the mass fraction of sodium oxide in the solution to 15%.

[0060] The admixture uses a water reducing agent with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com