A temperature transition method for hot-dip galvanized steel strip

A technology of hot-dip galvanizing and strip steel, applied in hot-dip galvanizing process, heat treatment process control, heat treatment furnace and other directions, it can solve the problems of quality loss, achieve qualified and stable performance, avoid flat pattern, rolling force and roll mode optimized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

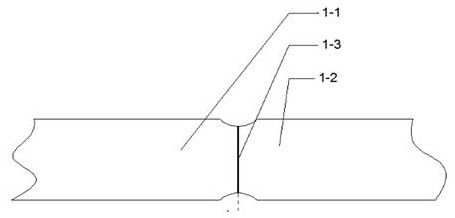

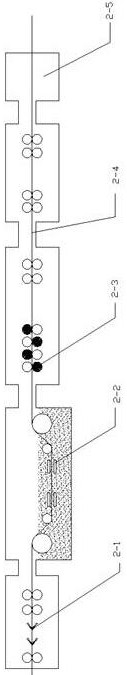

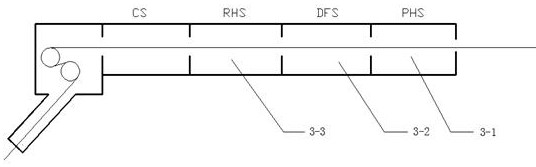

[0055] Embodiment 1: see Figure 1-Figure 5 , a hot-dip galvanized steel strip temperature transition method, the method may further comprise the steps:

[0056] Step 1: Control of the entry section;

[0057] Step 2: Control of the cleaning section;

[0058] Step 3: Control of the furnace section;

[0059] Step 4: Control of the air knife;

[0060] Step 5: Control of leveling and straightening;

[0061] Step 6: Post-processing and coiling.

[0062] Among them, step 1: the control of the entry section, the details are as follows:

[0063] 1.1 The transition value of the thickness is limited within 0.3mm;

[0064] The switching of the thickness directly affects the change of the annealing temperature of the strip steel. When the thickness changes and the operating speed of the unit remains unchanged, the annealing temperature is inversely proportional to the change of the thickness. If the thickness exceeds 0.3mm, it will be difficult to adjust, mainly Due to the slow res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com