Pre-aging method of 6016 aluminum alloy vehicle body plate

A pre-aging and aluminum alloy technology, which is applied in the field of aluminum alloys, can solve the problems of insufficient product market competitiveness, long production cycle, and low efficiency of equipment production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

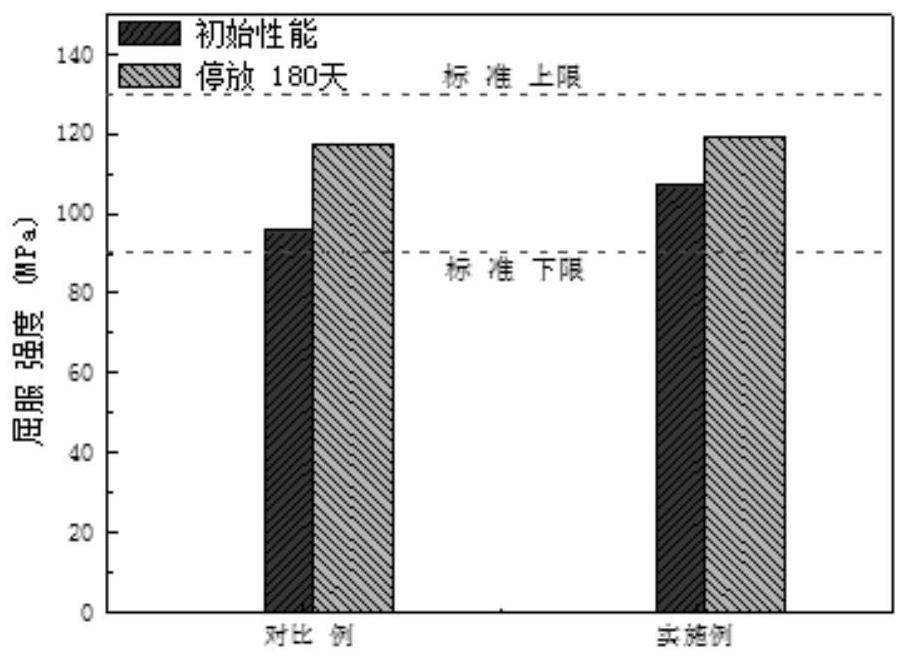

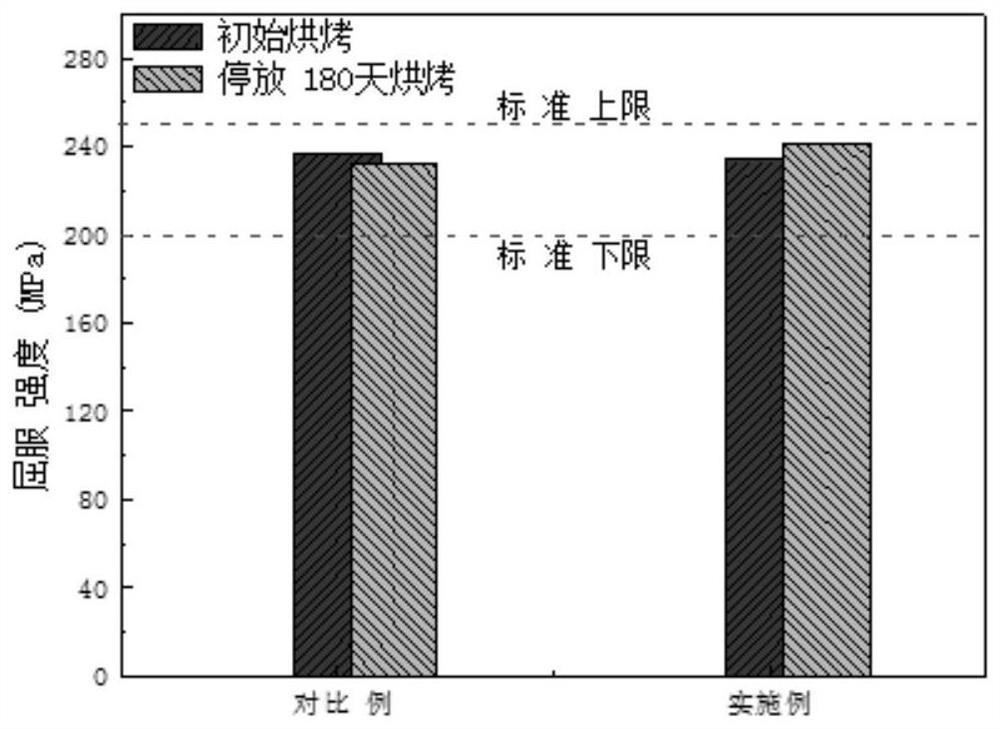

[0027] 6016 aluminum alloy body coils with a thickness of 0.8-3.0mm and a weight of more than 6 tons are used as materials to be heat-treated. The solution quenching adopts an air cushion furnace to heat the sheet to 550°C, and the solution is kept for 100s. Heat the sheet to 180°C, keep it warm for 1 minute, and complete the crimping and bundling for 2 hours after being out of the oven. Then transfer the whole roll and cool it to room temperature under natural conditions to take samples for testing performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com