A kind of alkyne functionalized covalent organic framework material and its synthesis method and application

A technology of covalent organic frameworks and synthetic methods, applied in chemical instruments and methods, separation methods, organic chemistry, etc., can solve problems such as inability to achieve industrialization, limited wide application, harshness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Synthesis of COF-TYOPE1 (R is OH):

[0039] Add 2,4,6-trihydroxybenzene-1,3,5-tricarbaldehyde (63.0mg, 0.299mmol), bis(4-aminophenyl)acetylene (98.8mg, 0.474mmol) into the standard tank, and then Add 10 mL of ionic liquid BmimTf 2 N(n=0, m=3, Y=Tf 2 N) and 0.5 mL (6 mol / L) of acetic acid aqueous solution; ultrasonically disperse the above reaction system evenly, seal it, and place it in a microwave reactor. The microwave power was set to 120W and the temperature was programmed to 120°C within 5 minutes. The reaction was continued at this temperature for 55 minutes to obtain a brownish-yellow solid. The crude product was obtained by centrifugation and 2 mL of N,N-dimethylformamide and 2 mL of acetone solvent Each was washed 3 times, and vacuum-dried at 120°C for 12 hours to obtain the alkyne-functionalized covalent organic framework COF-TYOPE1 (80% yield, specific surface area 1720m 2 / g).

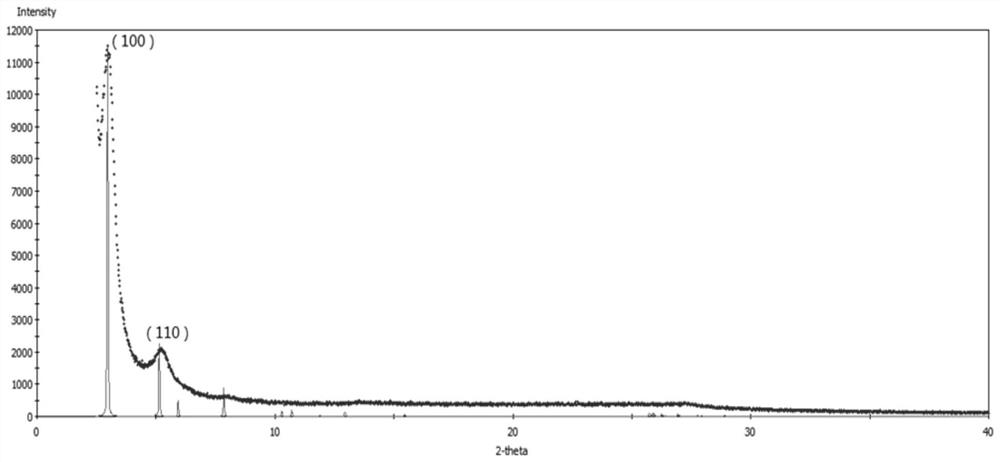

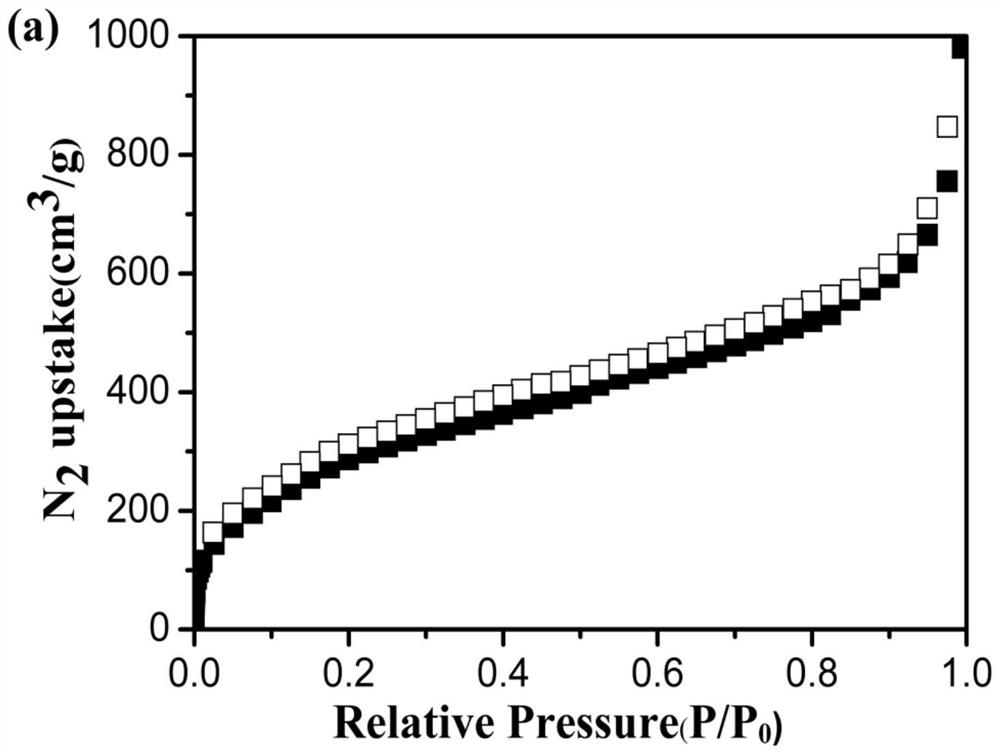

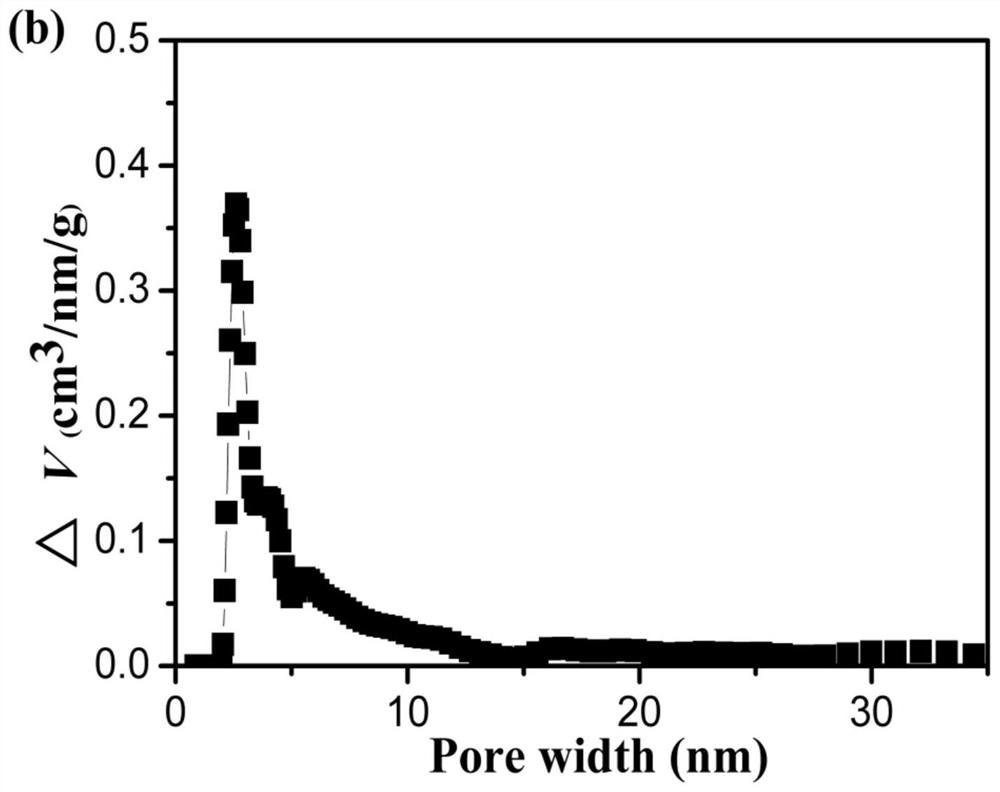

[0040] Implementation effect, the PXRD spectrum of the covalent organic fram...

Embodiment 2

[0042] COF-TYOPE2 (R is OCH 3 )Synthesis:

[0043] Get 2,4,6-methoxy-1,3,5-triformaldehyde (67.2mg, 0.299mmol), bis(4-aminophenyl)acetylene (98.8mg, 0.474mmol) was added to the standard tank, and then Add 10mL ionic liquid [Emim]Tf 2 N(n=0, m=1, Y=Tf 2 N) and 0.5 mL of 6mol / L acetic acid aqueous solution; ultrasonically disperse the above reaction system evenly, seal it, and place it in a microwave reactor. The microwave power was set to 120W and the temperature was programmed to 120°C within 5 minutes. The reaction was continued at this temperature for 55 minutes to obtain a brownish-yellow solid. The crude product was obtained by centrifugation and 2 mL of N,N-dimethylformamide and 2 mL of acetone solvent Each was washed 3 times, and vacuum-dried at 120° C. for 12 h to obtain the alkyne-functionalized covalent organic framework COF-TYOPE2 (the yield was 70%, and the specific surface area was 973m 2 / g).

Embodiment 3

[0045] COF-TYOPE3 (R is CH 3 )Synthesis:

[0046] Take 2,4,6-methyl-1,3,5-triformaldehyde (62.4mg, 0.299mmol), bis(4-aminophenyl)acetylene (98.8mg, 0.474mmol) into the standard tank, and then add 10mL ionic liquid BmimTf 2 N(n=0, m=3, Y=Tf 2 N) and 0.5 mL of 6mol / L acetic acid aqueous solution; ultrasonically disperse the above reaction system evenly, seal it, and place it in a microwave reactor. The microwave power was set to 120W and the temperature was programmed to rise to 120°C within 5 minutes, and the reaction was continued at this temperature for 55 minutes to obtain a brownish-yellow solid. The crude product was obtained by centrifugation and 2 mL of N,N-dimethylformamide and 2 mL of acetone solvent Each was washed 3 times, and vacuum-dried at 120° C. for 12 h to obtain the alkyne-functionalized covalent organic framework COF-TYOPE3 (yield 72%, specific surface area 700m 2 / g).

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com