Production method of ultra-deep drawing grade steel

A production method and deep-drawing technology, applied in the field of steel rolling, can solve the problems of unseen SEDDQ steel, and achieve the effects of qualified and stable performance, improved yield and good direct economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be noted that the following embodiments do not limit the present invention, and combinations and substitutions can be made between different embodiments.

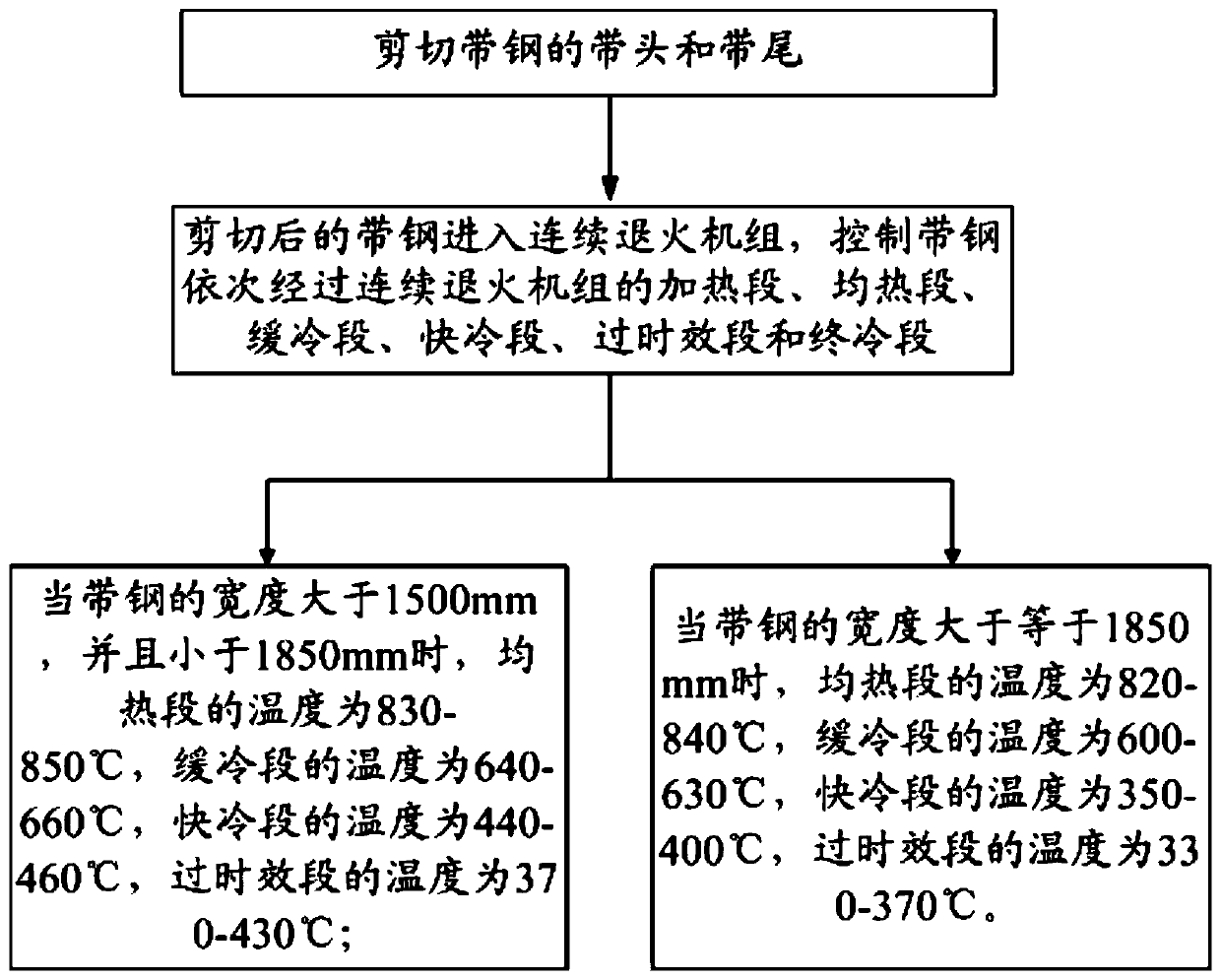

[0021] like figure 1 As shown, an embodiment of the present invention provides a method for producing ultra-extra deep-drawing grade steel, which includes: shearing the head and tail of the strip; the sheared strip enters the continuous annealing unit, and the strip is controlled to pass through in sequence The heating section, soaking section, slow cooling section, rapid cooling section, overaging section and final cooling section of the continuous annealing unit; among them, when the width of the strip is greater than 1500mm and less than 1850mm, the temperature of the soaking section is controlled to be 830 -850℃, the temperature of the slow cooling section is controlled to be 640-660℃...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com