Nanometer combustion-supporting and power-increasing additive for methanol fuel for M100 vehicles and preparation method of nanometer combustion-supporting and power-increasing additive

A technology of methanol and additives for vehicles is applied in the fields of combustion-supporting additive and preparation, nano-combustion-boosting additive and preparation, and can solve the problems of unsatisfactory rapid acceleration performance of vehicles, large fuel consumption, and driving up the operating cost of methanol vehicles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

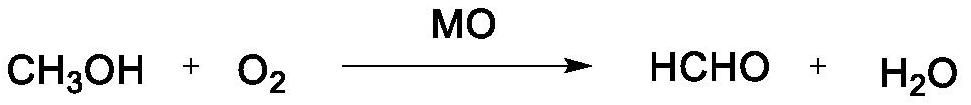

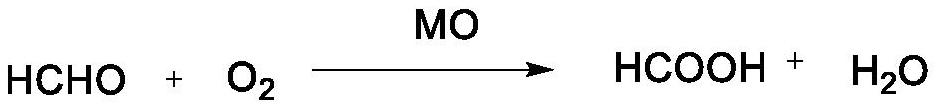

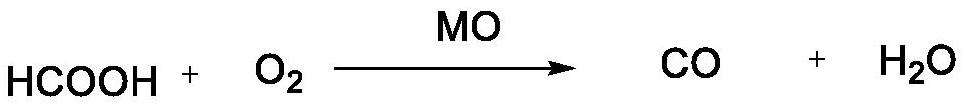

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: the nanometer combustion-supporting booster of M100 vehicle methanol fuel, by following raw material: 30 parts of nanometer cerium oxides, 30 parts of xylenes, 15 parts of naphthenates, 10 parts of ethylene glycol dimethyl ethers, N, N - 10 parts of dimethylaniline, prepared.

[0029] Preparation method: First, install a small mixer at the bottom of a stainless steel reaction kettle with a stirrer on the top, install outlet and inlet pipes and valves at the bottom of the stainless steel reaction kettle, and connect a valve with Shear pump with shear function; then raw materials: 30 parts of nano cerium oxide, 30 parts of xylene, 15 parts of naphthenate, 10 parts of ethylene glycol dimethyl ether, 10 parts of N, N-dimethylaniline, Add in the stainless steel container one by one, stop mechanically after 15 minutes under normal temperature and normal pressure environment, make the raw materials mix evenly physically, obtain the solution; start the shear pump ...

Embodiment 2

[0030] Embodiment 2: the nano-combustion-supporting booster of M100 vehicle methanol fuel, its raw material is: 30 parts of nano-lanthanum oxides, 35 parts of mesitylene, 10 parts of dimethyl carbonate, 10 parts of ethylenediaminetetraacetic acid, triethylenetetramine 10 servings.

[0031] Preparation method: add 30 parts of nanometer lanthanum oxide, 35 parts of mesitylene, 10 parts of dimethyl carbonate, 10 parts of ethylenediaminetetraacetic acid and 10 parts of triethylenetetramine into a stainless steel reaction kettle in sequence, Start the mixer under the environment to stir for 15 minutes, then stop it, and then start the shear pump, through which the solution in the stainless steel reactor is pumped out and circulated, and transported to the mixer at the bottom of the stainless steel reactor through the pipeline for further physical mixing. The physical effect of the shear pump and the mixer makes the solution molecules fuse into a nano-mixture, and the shear pump run...

Embodiment 3

[0032]Embodiment 3: the nano-combustion-supporting booster of M100 methanol fuel for vehicles, the raw materials are: 35 parts of the mixture of nano-nickel oxide or nano-cerium oxide, nano-lanthanum oxide, 30 parts of the mixture of acetone and trimethylbenzene, naphthenate, ethyl alcohol 15 parts of a mixture of diaminetetraacetic acid, 10 parts of a mixture of ethylene glycol dimethyl ether, dimethyl carbonate, and isopropanol, and 10 parts of a mixture of triethylenetetramine, hydroquinone, and N,N-dimethylaniline share.

[0033] Preparation method: 35 parts of a mixture of nano-nickel oxide or nano-cerium oxide and nano-lanthanum oxide, 30 parts of a mixture of acetone and trimethylbenzene, 15 parts of a mixture of naphthenate and ethylenediaminetetraacetic acid, ethylene glycol dimethyl Add 10 parts of a mixture of ether, dimethyl carbonate, and isopropanol, and 10 parts of a mixture of triethylenetetramine, hydroquinone, and N,N-dimethylaniline into a stainless steel re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com