A continuous process for preparing mesophase pitch from refined raw material oil

A technology of mesophase pitch and raw oil, which is applied in the processing of tar pitch/petroleum pitch/natural pitch, the petroleum industry, and distillation processing of tar pitch/petroleum pitch/natural pitch, etc., to achieve high universality and promote dissolution and penetration The effect of reducing the transmembrane pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

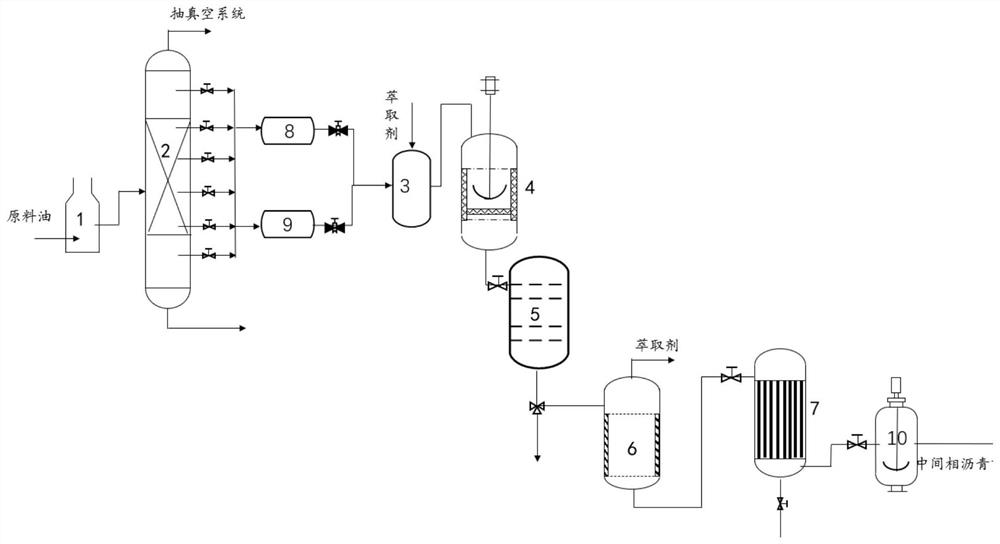

[0032] Put ethylene tar into the normal pressure heating furnace, heat it to 200°C and input it into the decompression precision fractionation unit, the absolute pressure is 5kPa, the decompression precision deep drawing separates the distillate above 300°C, opens the corresponding valve, and introduces the distillate into the ultrasonic chamber Chemical-filtration-solvent extraction integrated unit, select ceramic membrane with a pore size of 20nm as the filter membrane, add the extraction agent N,N-dimethylformamide, the solvent-oil ratio is 2, and the flow rate is 1m 3 / h, at a temperature of 60°C and an ultrasonic power of 600W for 60 minutes, the obtained raw material oil was subjected to static sedimentation and solvent oil separation to obtain the aromatic carbon rate (C A ) and naphthenic carbon ratio (C N ) between 35% and 65%, the absolute change rate of aroma and colloid group composition is >2.0%, and the ash content is ≤20μg / g;

[0033] The aromatic-rich distilla...

Embodiment 2

[0037] Put the coal tar into the normal-pressure heating furnace, heat it to 150°C, and input it into the vacuum precision fractionation unit. The absolute pressure is 7kPa, and the vacuum precision deep drawing separates the distillate above 300°C. Open the corresponding valve and introduce the distillate into the ultrasonic chamber. Chemical-filtration-solvent extraction integrated unit, select ceramic membrane with a pore size of 100nm as the filter membrane, add extraction agent N-methylpyrrolidone, the ratio of agent to oil is 4, and the flow rate is 0.8m 3 / h, at a temperature of 80°C and an ultrasonic power of 700W for 50 minutes, the obtained raw material oil was subjected to static sedimentation and solvent oil separation, and the aromatic carbon rate (C A ) and naphthenic carbon ratio (C N ) between 35% and 65%, the absolute change rate of aroma and colloid group composition is >2.0%, and the ash content is ≤20μg / g;

[0038] The aromatic-rich distillate oil is intro...

Embodiment 3

[0042] Take 2.0kg of catalytic oil slurry and add it to the vacuum precision fractionation unit. The temperature of entering the tower is 150°C and the absolute pressure is 5KPa. The fraction oil above 300°C is separated by vacuum precision deep drawing, and the corresponding valve is opened to introduce the fraction oil and the extractant at the same time. Ultrasonic cavitation-filtration-solvent extraction integrated unit, using a ceramic membrane with a pore size of 150nm, the extraction agent is N,N-dimethylformamide, the solvent-oil ratio is 2, the power of the ultrasonic generator is adjusted to 600W, at 80°C Under the conditions of extraction and filtration, after the extraction is completed, the filtrate is subjected to static sedimentation and solvent oil separation, and the treated raw material oil is introduced into the liquid-solid adsorption chromatographic separation unit. As the mobile phase, the activated silica gel is used as the stationary phase to perform liq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com