Reinforced polyphenylene sulfide composite material with low floating fiber, low warping and high glass fiber content, and preparation method thereof

A technology with high glass fiber content and polyphenylene sulfide, applied in the direction of coating, etc., can solve problems such as poor compatibility, rough surface, and many floating fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

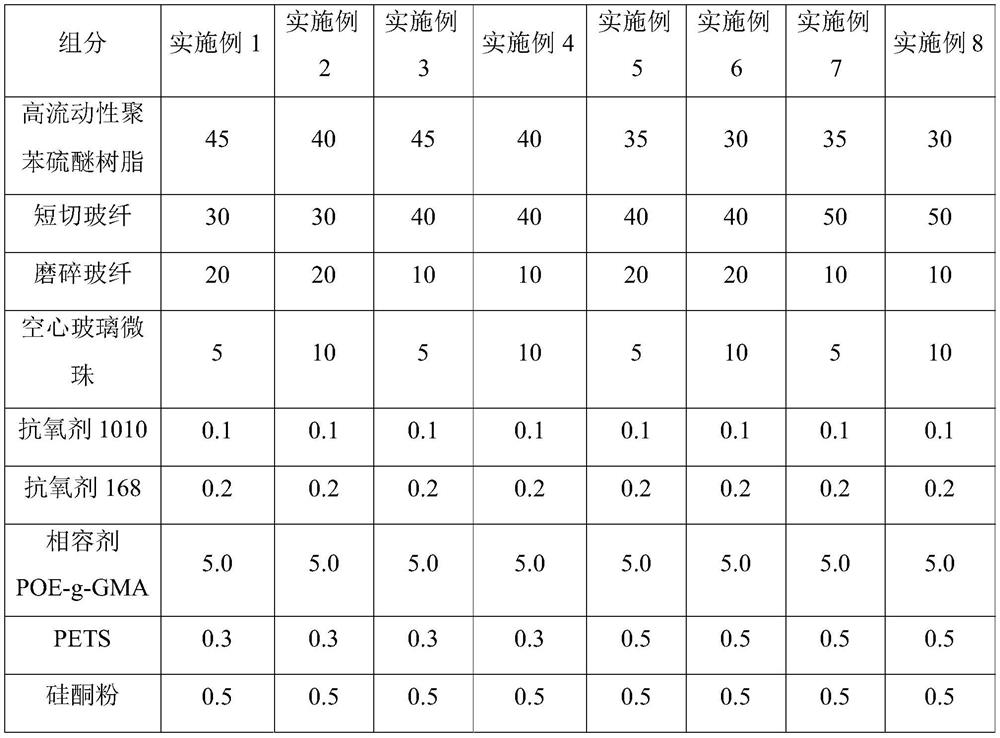

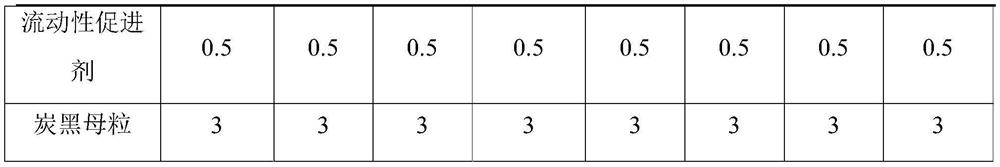

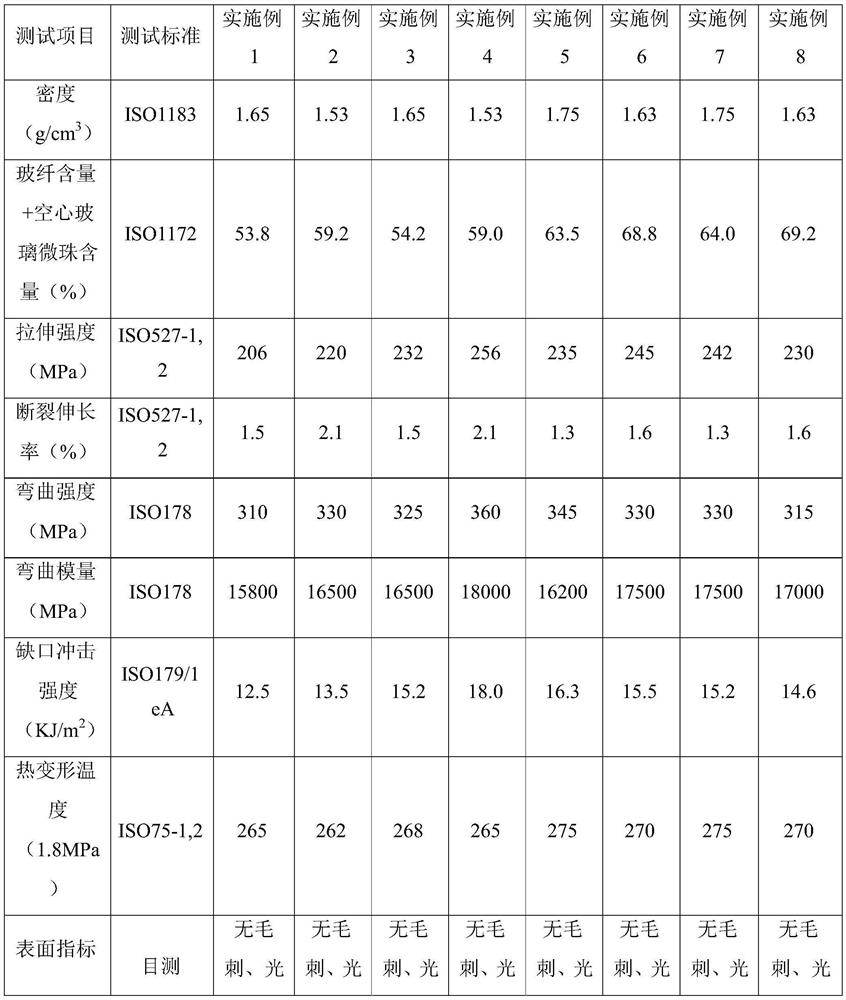

Examples

Embodiment 1

[0051] (1) Preparation of carbon black masterbatch

[0052] Take 50 parts of high fluidity polyphenylene sulfide, 50 parts of carbon black CABOT 2014N, 10100.1 parts of antioxidant, 0.2 part of antioxidant 168, and 0.7 part of silicone powder by weight, and mix the above materials in a high-speed mixer Evenly, the mixed mixture is added to the extruder through the main feeding port, followed by extrusion, strand drawing, water cooling and pelletizing machine granulation processes, and finally dried to obtain carbon black master batches, wherein the processing temperature is determined by Zone 1 to zone 9 are 200°C, 260°C, 280°C, 280°C, 290°C, 290°C, 290°C, 280°C, 270°C respectively, the speed is 300r / min, and the feeding speed is 20r / min;

[0053] (2) Preparation of reinforced polyphenylene sulfide composites

[0054] Weigh by weight 0.1 part of antioxidant 1010, 0.2 part of antioxidant 168, 5.0 part of compatibilizer POE-g-GMA, 0.3 part of lubricant PETS, 0.5 part of silicon...

Embodiment 2

[0061] Weigh 0.1 part of antioxidant 1010, 0.2 part of antioxidant 168, 5.0 part of compatibilizer POE-g-GMA, 0.3 part of lubricant PETS, 0.5 part of silicone powder, 0.5 part of flow promoter and Example 1 3 parts of the carbon black masterbatch prepared in the above method, after being dispersed and mixed by a high-speed mixer, 40 parts of the mixed above-mentioned mixture and high-fluidity polyphenylene sulfide resin were added into the extruder from the main feeding port through the corresponding weight loss weighing scale. Getting out of the plane. At the same time, 30 parts of chopped glass fibers were weighed by weight loss and added to the extruder through the 1# side feed port of the plasticizing section located in the fourth temperature zone, and 20 parts of ground glass fibers and 10 parts of hollow glass beads were passed through The 2# side feed port of the plasticizing section located in the fifth temperature zone is fed into the extruder, followed by extrusion, ...

Embodiment 3

[0067] Weigh 0.1 part of antioxidant 1010, 0.2 part of antioxidant 168, 5.0 part of compatibilizer POE-g-GMA, 0.3 part of lubricant PETS, 0.5 part of silicone powder, 0.5 part of flow promoter and Example 1 3 parts of the carbon black masterbatch prepared in the above method, after being dispersed and mixed by a high-speed mixer, 45 parts of the mixed above-mentioned mixture and high-fluidity polyphenylene sulfide resin were added into the extruder from the main feeding port through the corresponding weight loss weighing scale. Getting out of the plane. At the same time, 40 parts of chopped glass fiber was weighed by weight loss and added to the extruder through the 1# side feed port of the plasticizing section located in the fourth temperature zone, and 10 parts of ground glass fiber and 5 parts of hollow glass microspheres were passed through The 2# side feed port of the plasticizing section located in the fifth temperature zone is fed into the extruder, followed by extrusio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com