Viscosity modifier for concrete and preparation method thereof

A viscosity regulator and concrete technology, applied in the field of concrete admixtures, can solve the problems of poor compatibility of polycarboxylate superplasticizers, etc., and achieve the effects of facilitating the development of mechanical strength, solving poor compatibility and large steric hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of preparation method of concrete viscosity modifier of the present embodiment, comprises following preparation steps:

[0031] (1) The molar ratios of γ-methacryloxypropyltrimethoxysilane and heptadecylfluorodecyltrimethoxysilane are 1:1, 1:1.5, 1:2, 1:2.5, 1 :3 and 1:4 were added to the isopropanol solvent, stirred and dissolved evenly, deionized water was added dropwise at room temperature for hydrolysis and polycondensation, after the reaction was completed, the low boilers were evaporated under reduced pressure to obtain silane-modified monomers.

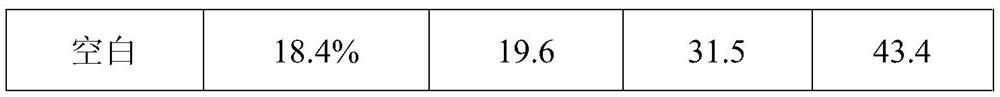

[0032] The morphology / viscosity (mPa·s), average molecular weight, and yield of the silane-modified monomers were measured at different molar ratios, and the results are shown in Table 1 below.

[0033] Table 1

[0034] 1:1 1:1.5 1:2 1:2.5 1:3 1:4 Form / Viscosity gelation 14000 520 330 190 120 molecular weight 230,000 28000 7400 3500 1800 880 Yield 96% 95% 95% 93% 8...

Embodiment 2

[0038] A kind of preparation method of concrete viscosity modifier of the present embodiment, comprises following preparation steps:

[0039] (1) Add γ-methacryloxypropyltrimethoxysilane to heptadecylfluorodecyltrimethoxysilane with a molar ratio of 1:2.5 into the isopropanol solvent, stir and dissolve evenly, add dropwise at room temperature Deionized water is used for hydrolysis and polycondensation, and after the reaction is completed, the low boilers are evaporated under reduced pressure to obtain a silane-modified monomer.

[0040] (2) Add acrylic acid, acrylamide, N,N'-methylenebisacrylamide and peroxide initiator ammonium persulfate into water and stir to dissolve evenly, then pass nitrogen to remove oxygen and heat up to 40-70°C, drop Add a mixed solution containing silane-modified monomer (1:2.5 product) and reducing agent sodium hypophosphite for copolymerization, wherein the mass ratio of acrylic acid to acrylamide is 1:2, N,N'-methylenebispropylene The addition am...

Embodiment 3

[0042] A kind of preparation method of concrete viscosity modifier of the present embodiment, comprises following preparation steps:

[0043] (1) Add γ-methacryloxypropyltrimethoxysilane to heptadecylfluorodecyltrimethoxysilane with a molar ratio of 1:2.5 into the isopropanol solvent, stir and dissolve evenly, add dropwise at room temperature Deionized water is used for hydrolysis and polycondensation, and after the reaction is completed, the low boilers are evaporated under reduced pressure to obtain a silane-modified monomer.

[0044](2) Add acrylic acid, acrylamide, N,N'-methylenebisacrylamide and peroxide initiator ammonium persulfate into water and stir to dissolve evenly, then pass nitrogen to remove oxygen and heat up to 40-70°C, drop Add a mixed solution containing silane-modified monomer (1:2.5 product) and reducing agent sodium hypophosphite for copolymerization, wherein the mass ratio of acrylic acid to acrylamide is 1:2, N,N'-methylenebispropylene The addition amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com