Method for preparing high-strength foamed ceramic from solid waste

A technology of solid waste and foamed ceramics, which is applied in the production and application of ceramic products and ceramic materials, and can solve problems such as hindering the growth of pores.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

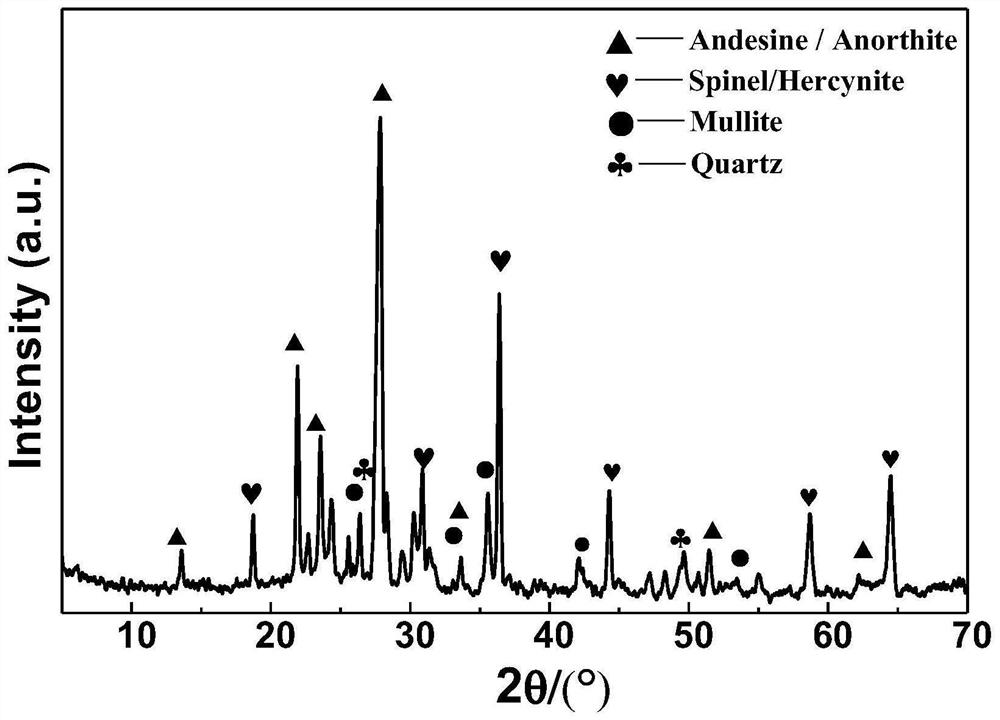

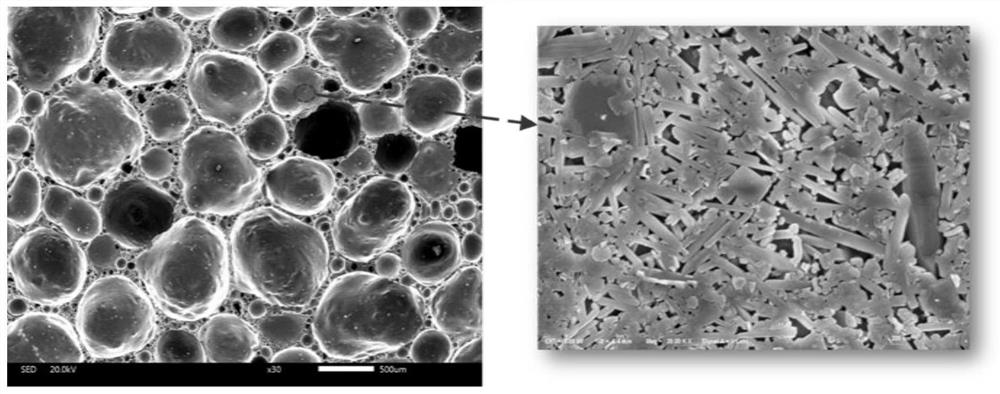

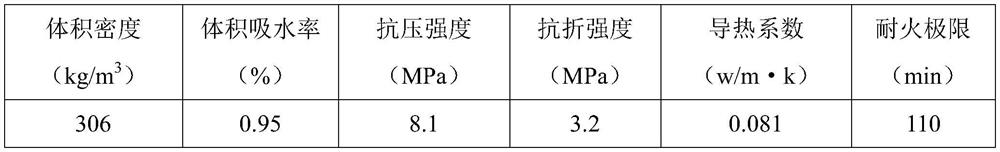

Embodiment 1

[0028] 1) Dry the fly ash, coal-fired slag, copper tailings, and chromium-containing sludge, and grind them to a particle size of <75 μm;

[0029] 2) Weigh the ingredients according to the ratio of fly ash: coal-fired slag: copper tailings: chromium-containing sludge = 20%: 10%: 50%: 20%, and add 0.35% composite blowing agent and 0.15% The dispersant is mixed and ground in a steel ball mill for 3 hours to make a uniformly mixed billet, and the fineness of the billet is 2.0% after sieving through a 45 μm square hole sieve;

[0030] 3) Add 3% polycrystalline mullite fiber with a diameter of 20 μm and a length of 60 to 100 μm as a reinforcing agent to the billet, and add tap water of equal quality, and stir at a high speed in a planetary mortar mixer for 15 minutes to make a uniform slurry;

[0031] 4) Dry the slurry in a hot air drying oven, crush it into powder, and then fill it in a cordierite refractory mold with refractory fiber paper, with a thickness of 6±1mm. In a box-ty...

Embodiment 2

[0037] 1) Dry coal gangue, coal-fired slag, copper tailings, lithium tailings, and chromium-containing sludge, and grind them to a particle size of <75 μm;

[0038]2) Weigh the ingredients according to the ratio of coal gangue: coal-fired slag: copper tailings: lithium tailings: chromium-containing sludge = 5%: 25%: 35%: 20%: 15%, and add 0.25% compound Foaming agent and 0.15% dispersant are mixed and ground in a steel ball mill for 3 hours to make a uniformly mixed billet, the fineness of which is 2.1% after sieving through a 45 μm square hole sieve;

[0039] 3) Add 4% alumina fibers with a diameter of 15 μm and a length of 100 to 200 μm as a reinforcing agent to the billet, and add tap water of equal quality, and stir at high speed in a planetary mortar mixer for 20 minutes to make a uniform slurry;

[0040] 4) Dry the slurry in a hot air drying oven, crush it into powder, and then fill it in a cordierite refractory mold with refractory fiber paper, with a thickness of 6±1mm...

Embodiment 3

[0046] 1) Dry coal-fired slag, copper tailings, and chromium-containing sludge, and grind them to a particle size of <75 μm;

[0047] 2) Weigh the ingredients according to the ratio of coal-fired slag: copper tailings: chromium-containing sludge = 30%: 45%: 25%, and add 0.15% composite foaming agent and 0.15% dispersant, in the steel ball mill Medium mixing and grinding for 4 hours to make a uniformly mixed billet, the fineness of which is 1.2% after sieving through a 45 μm square hole sieve;

[0048] 3) Add 4% carbon fiber with a diameter of 5 μm and a length of 200 μm as a reinforcing agent to the blank, and add tap water of equal quality, and stir at a high speed in a planetary mortar mixer for 15 minutes to make a uniform slurry;

[0049] 4) Dry the slurry in a hot air drying oven, crush it into powder, and then fill it in a cordierite refractory mold with refractory fiber paper, with a thickness of 6±1mm. In a box-type electric furnace, the temperature was raised to 1195...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com