Dust removal and desulfurization integrated silicon nitride porous ceramic and preparation method thereof

A technology of porous ceramics and silicon nitride, which is applied in the field of porous ceramics and can solve problems such as increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

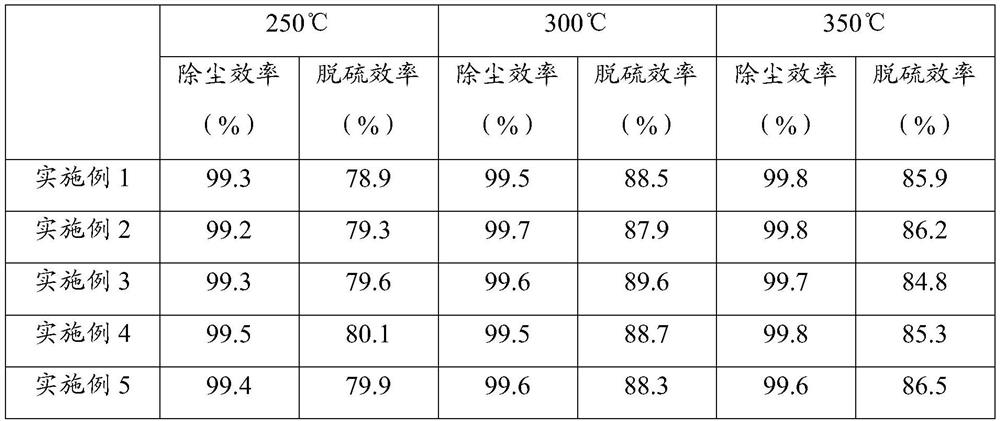

Examples

Embodiment 1

[0027] A silicon nitride porous ceramic integrating dust removal and desulfurization. The reaction raw materials are extruded and sintered to obtain porous ceramics. The desulfurization catalyst is loaded on the surface of the porous ceramics by impregnation or spraying. The reaction raw materials are proportioned in parts by mass It consists of 100 parts of rice husk, 10 parts of silicon nitride, 14 parts of sintering aid, 1 part of pore-forming agent and 6 parts of low-temperature glass fusion powder, wherein the rice husk is soaked in dilute hydrochloric acid with a volume fraction of 8% for 20 days. It was obtained by boiling in dilute hydrochloric acid with a volume fraction of 8% for 10 minutes, cooling to room temperature, boiling again, repeating 3 times, and then drying.

[0028] Specifically, the desulfurization catalyst is quicklime.

[0029] Specifically, the sintering aid is alumina.

[0030] Specifically, the pore former is graphite.

[0031] Specifically, the ...

Embodiment 2

[0043] A silicon nitride porous ceramic integrating dust removal and desulfurization. The reaction raw materials are extruded and sintered to obtain porous ceramics. The desulfurization catalyst is loaded on the surface of the porous ceramics by impregnation or spraying. The reaction raw materials are proportioned in parts by mass It consists of 100 parts of rice husk, 20 parts of silicon nitride, 20 parts of sintering aid, 10 parts of pore-forming agent and 10 parts of low-temperature glass fusion powder, wherein the rice husk is soaked in dilute hydrochloric acid with a volume fraction of 12% for 50 days. It was obtained by boiling in dilute hydrochloric acid with a volume fraction of 12% for 30 minutes, cooling to room temperature, boiling again, repeating 5 times, and then drying.

[0044] Specifically, the desulfurization catalyst is limestone.

[0045] Specifically, the sintering aid is yttrium oxide.

[0046] Specifically, the pore former is graphite.

[0047] Specifi...

Embodiment 3

[0059] A silicon nitride porous ceramic integrating dust removal and desulfurization. The reaction raw materials are extruded and sintered to obtain porous ceramics. The desulfurization catalyst is loaded on the surface of the porous ceramics by impregnation or spraying. The reaction raw materials are proportioned in parts by mass It consists of 100 parts of rice husk, 15 parts of silicon nitride, 16 parts of sintering aid, 5 parts of pore-forming agent and 8 parts of low-temperature glass fusion powder, wherein the rice husk is soaked in dilute hydrochloric acid with a volume fraction of 10% for 30 days. It was obtained by boiling in dilute hydrochloric acid with a volume fraction of 10% for 20 minutes, cooling to room temperature, boiling again, repeating 4 times, and then drying.

[0060] Specifically, the desulfurization catalyst is quicklime.

[0061] Specifically, the sintering aid is yttrium oxide.

[0062] Specifically, the pore former is graphite.

[0063] Specifica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com