Turbine guider blade cooling device with low-melting-point metal as flowing working medium

A technology for turbine guides and low-melting-point metals, applied in the direction of blade support components, engine components, engine functions, etc., can solve the problem of reducing engine thermal efficiency and working ability, increasing aerodynamic loss of main gas flow, and aggravating heat loss of main gas flow and other problems, to achieve the effect of increasing propulsion power, prolonging service life and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

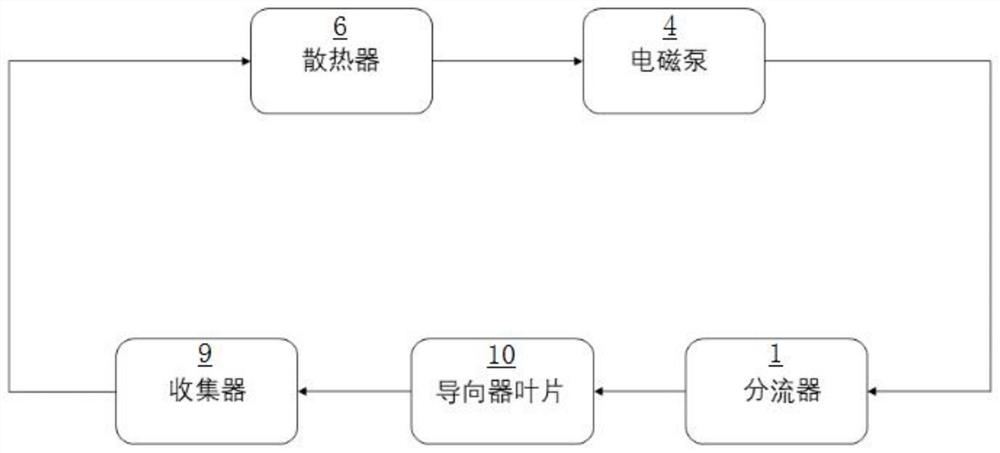

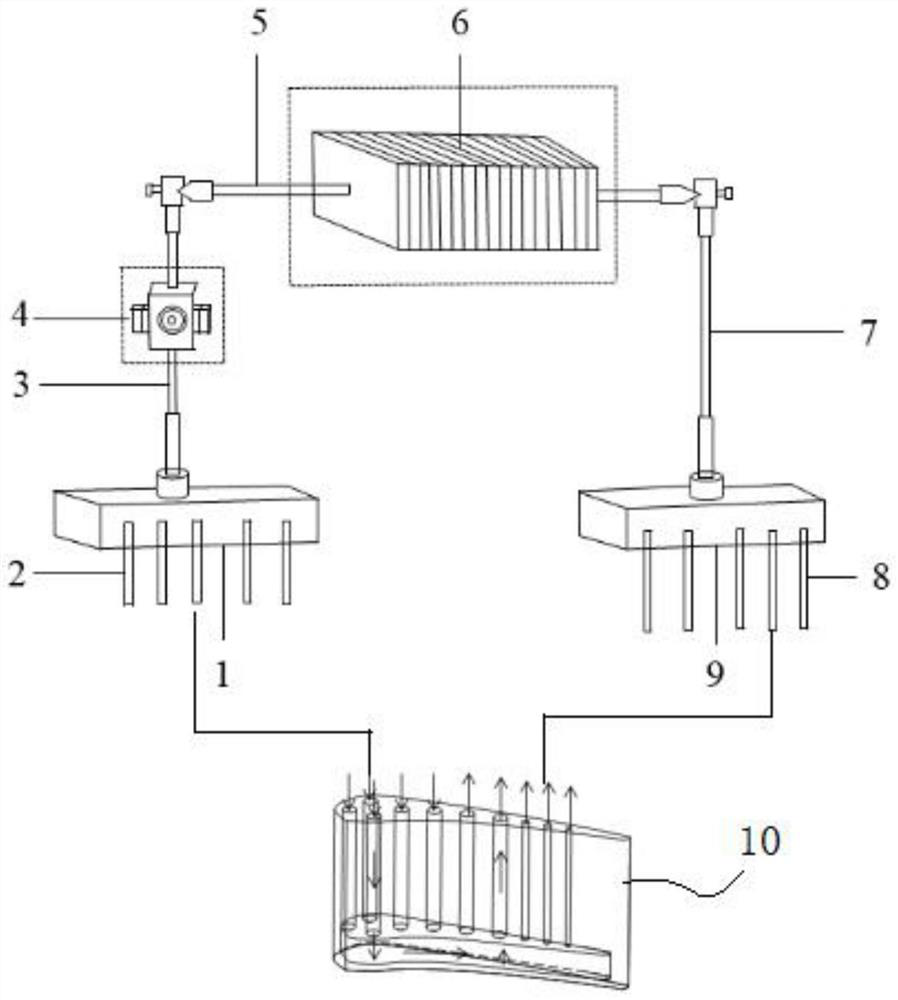

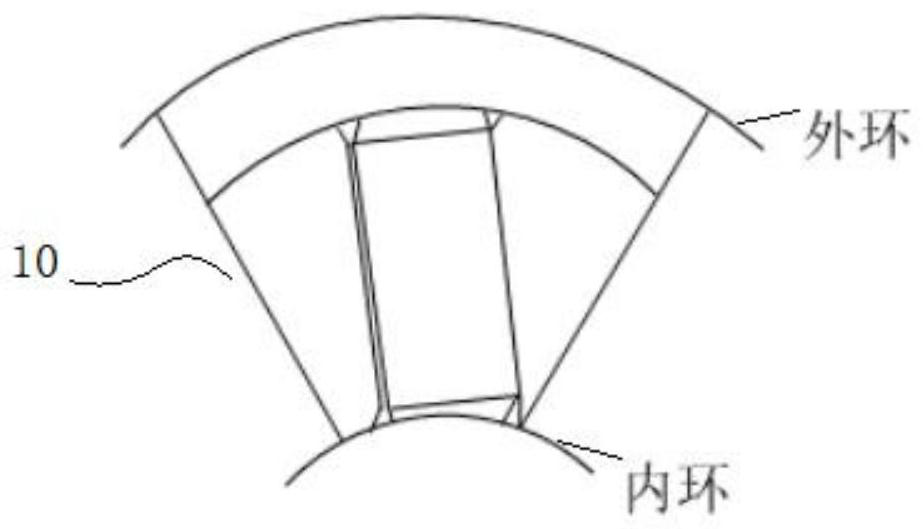

[0030] figure 1 It is a schematic logic control diagram of a turbine guide vane cooling device using a low-melting point metal as a working medium according to an embodiment of the present application. figure 2 It is a schematic structural diagram of a turbine guide vane cooling device in which the low-melting point metal in the outer part of the guide vane outer ring is used as a working medium. image 3 is a schematic structural diagram of a guide vane. Figure 4 is a schematic perspective view of the guide vane.

[0031] Such as Figure 4 As shown, in this embodiment, multiple cooling passages are arranged in the guide vane 10 . A cavity 13 is reserved at a bottom position inside the deflector vane 10 . Each cooling channel communicates with said chamber 13 . Part of the cooling passages in the plurality of cooling passages are cooling passages 11 that flow into the blade, and the rest of the cooling passages in the plurality of cooling passages are cooling passages 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com