Titanium alloy surface ion carbonitriding treatment device

A technology of carbonitriding and processing equipment, which is applied in the direction of metal material coating process, cleaning hollow objects, chemical instruments and methods, etc., can solve the problems of high brittleness, low bonding force, thin nitride layer, etc., and achieve high temperature stability Guaranteed durability, enhanced adhesion and density, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

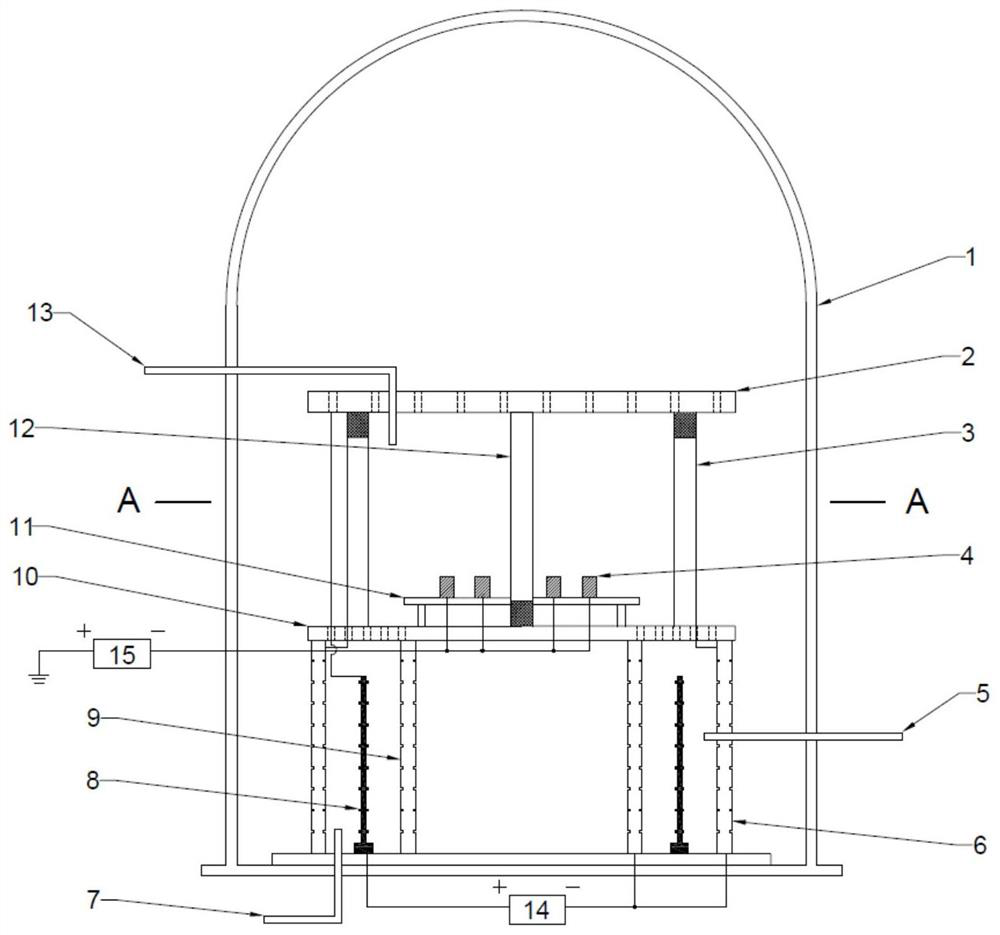

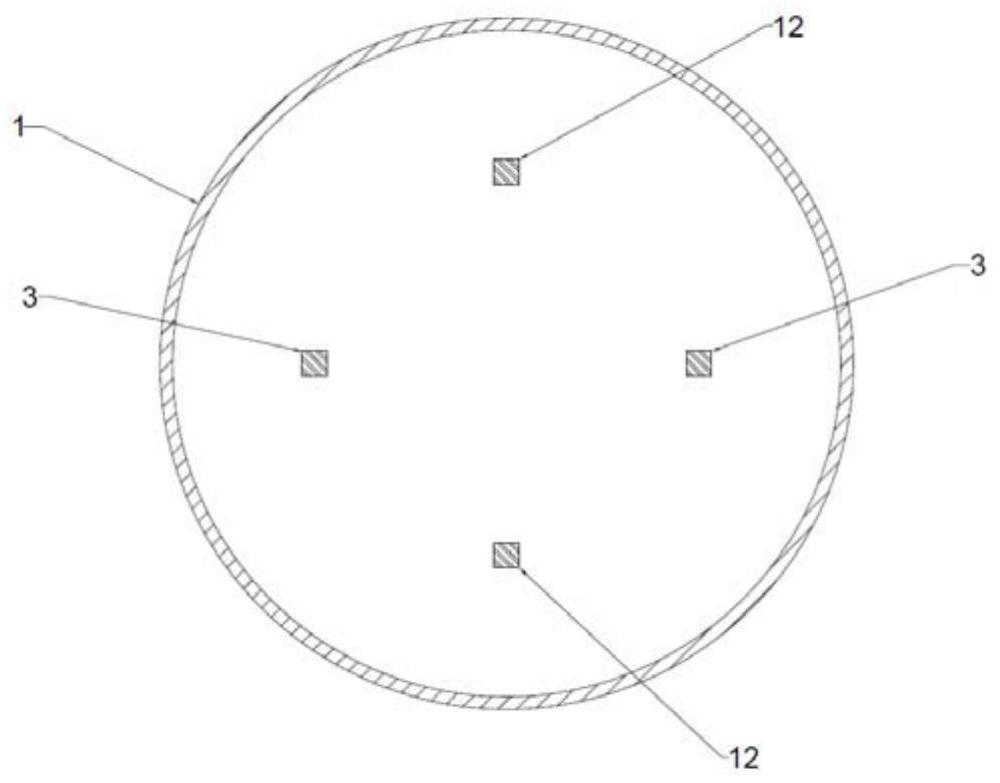

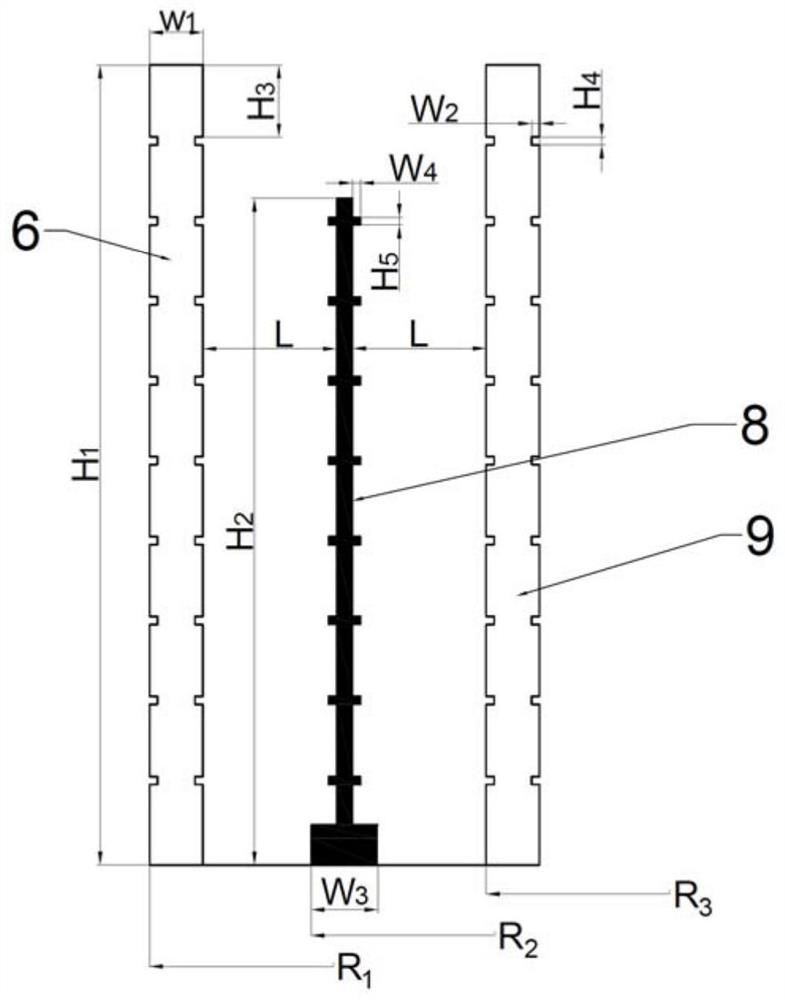

[0024] The titanium alloy surface ion carbonitriding treatment device that the present invention proposes, its structure is as follows figure 1 As shown, it includes infiltration furnace 1, anode top cover 2, cathode metal column 3, outer layer auxiliary cathode cylinder 6, inner layer auxiliary cathode cylinder 9, anode cylinder 8, insulating support plate 10, workpiece table 11, anode metal column 12 , a DC power supply 14 and a bias power supply 15; the outer layer auxiliary cathode cylinder 6, the anode cylinder 8 and the inner layer auxiliary cathode cylinder 9 are coaxially installed in the bottom of the infiltration furnace 1 cavity from outside to inside in turn, and the outer layer The auxiliary cathode cylinder 6, the anode cylinder 8 and the inner layer auxiliary cathode cylinder 9 are respectively connected to the positive and negative poles of the DC power supply 14, and the upper end of the anode cylinder 8 is lower than the upper ends of the outer layer auxiliary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com