A kind of preparation method of titanium alloy plate material

A technology for titanium alloys and plates is applied in the preparation of titanium alloy plates and in the fields of titanium and titanium alloy processing, which can solve the problems of short alloying time, increased production costs, and difficulty in controlling alloy components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

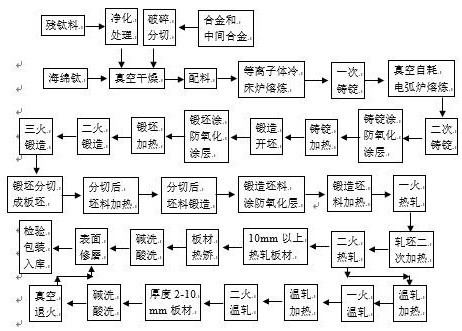

[0039] Embodiment: thickness is 20mm and thickness is that the TC4 plate production technology of 3.2mm is:

[0040] The above purpose is achieved through the following scheme:

[0041] 1. Titanium alloy ingot casting: alloy casting includes the following steps

[0042] ⑴Select high-quality grade 0 sponge titanium with impurity content not exceeding 0.3%, titanium content not less than 99.7%, double grade 0 electrolytic aluminum ingots and Al-80V master alloy as raw materials. Because the size of the raw material is too large, it is easy to cause segregation and inclusion of alloy components. Before the raw material treatment, it is necessary to cut the electrolytic aluminum ingot into a block with a particle size of 8-12.7mm for later use, and crush and screen the Al-80V master alloy to The particle size of 3-12.7mm is reserved.

[0043] (2) Send the prepared electrolytic aluminum, aluminum-vanadium master alloy and sponge titanium into the drying furnace for drying. All ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com