Preparation method of decorative wall brick and decorative wall brick

A decorative and wall tile technology, applied in the field of building materials, can solve the problems of inaccurate color registration, high cost of small batch production, and increased product scrap rate, achieve low raw material cost and equipment operation cost, and improve surface wear resistance and anticorrosion performance , Increase the effect of decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

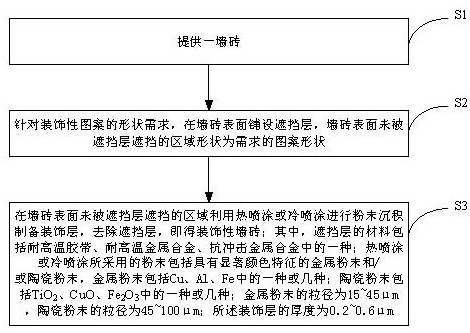

[0029] The invention provides a preparation method of decorative wall tiles, such as figure 1 shown, including the following steps:

[0030] S1. Provide a wall brick;

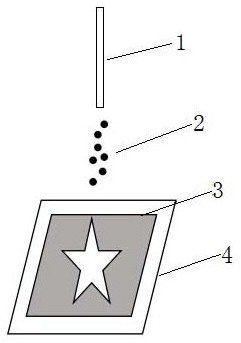

[0031] S2. According to the shape requirements of the decorative pattern, lay a shielding layer on the surface of the wall tiles, and the shape of the area on the surface of the wall tiles that is not blocked by the shielding layer is the required pattern shape;

[0032] S3. Use thermal spraying or cold spraying to prepare a decorative layer by powder deposition on the area not covered by the shielding layer on the surface of the wall tile, and remove the shielding layer to obtain a decorative wall tile;

[0033] Wherein, the material of the shielding layer includes one of high temperature resistant tape, high temperature resistant metal alloy, and impact resistant metal alloy;

[0034] The powder used in thermal spraying or cold spraying includes metal powder and / or ceramic powder with significant color char...

Embodiment 1

[0053] The embodiment of the present application provides a method for preparing decorative wall tiles, comprising the following steps:

[0054] S1. Provide a wall brick;

[0055] S2. Use high-temperature-resistant glue to lay a shielding layer on the surface of the wall tiles, so that the part of the wall brick surface that is not shielded by the shielding layer is in the shape of a five-pointed star; wherein, the shielding layer is PET high-temperature-resistant adhesive tape;

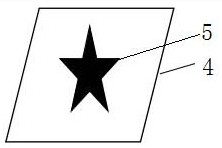

[0056] S3. Use cold spraying to prepare the decorative layer on the part of the wall brick surface that is not blocked by the shielding layer, wherein the raw material for cold spraying is pure Al powder, the working pressure of cold spraying is 3.5MPa, the temperature is 350°C, the spraying distance is 40mm, and the spray gun moves The speed is 25 mm / s, and the thickness of the prepared decorative layer is 0.3 mm. After the shielding layer is removed, a wall tile with a silver-white metallic luster...

Embodiment 2

[0060] The embodiment of the present application provides a method for preparing decorative wall tiles, comprising the following steps:

[0061] S1. Provide a wall brick;

[0062]S2. Use high-temperature-resistant glue to lay a shielding layer on the surface of the wall brick, so that the part of the wall brick surface that is not shielded by the shielding layer is in the shape of a landscape pattern; wherein, the shielding layer is a steel sheet;

[0063] S3, adopt the cold spraying method to prepare the decorative layer on the part of the wall brick surface that is not blocked by the shielding layer, wherein the raw material for the cold spraying is spherical Cu powder, the particle size of the Cu powder is 15 ~ 45 μm, and the working pressure of the cold spraying is 3.5MPa, The temperature is 500°C, and the moving speed of the spray gun is 50mm / s. When spraying the parts that need to be protruded in the landscape pattern, such as mountains and trees, control the moving spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com