Copper-containing bioactive glass dressing and preparation method thereof

A bioactive glass and sol technology, applied in the field of biomedicine, can solve problems such as cell environment damage, and achieve the effects of simple synthesis steps, mild synthesis steps and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

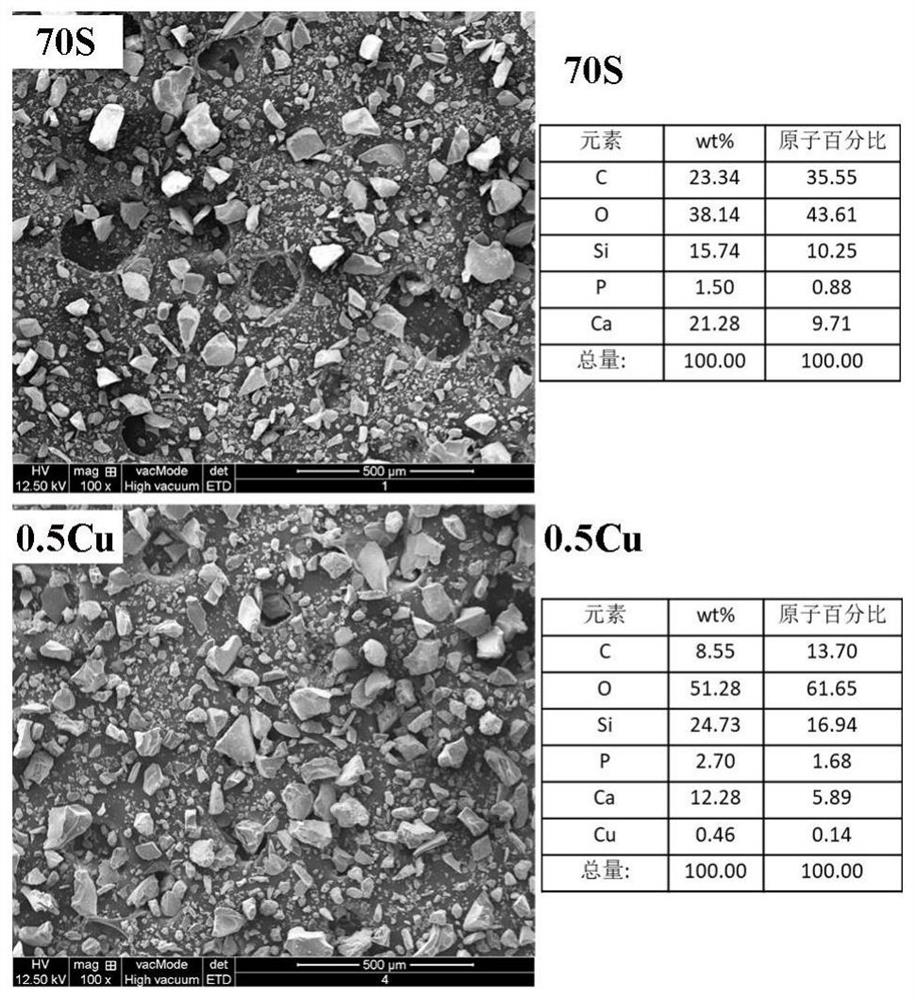

Embodiment 1

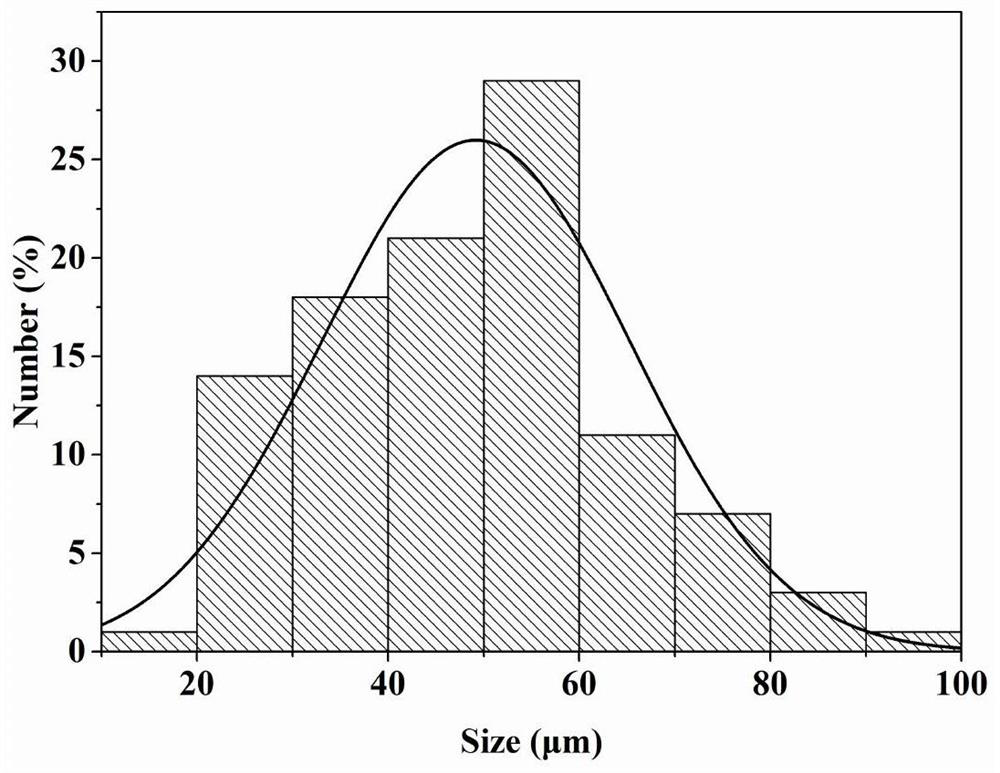

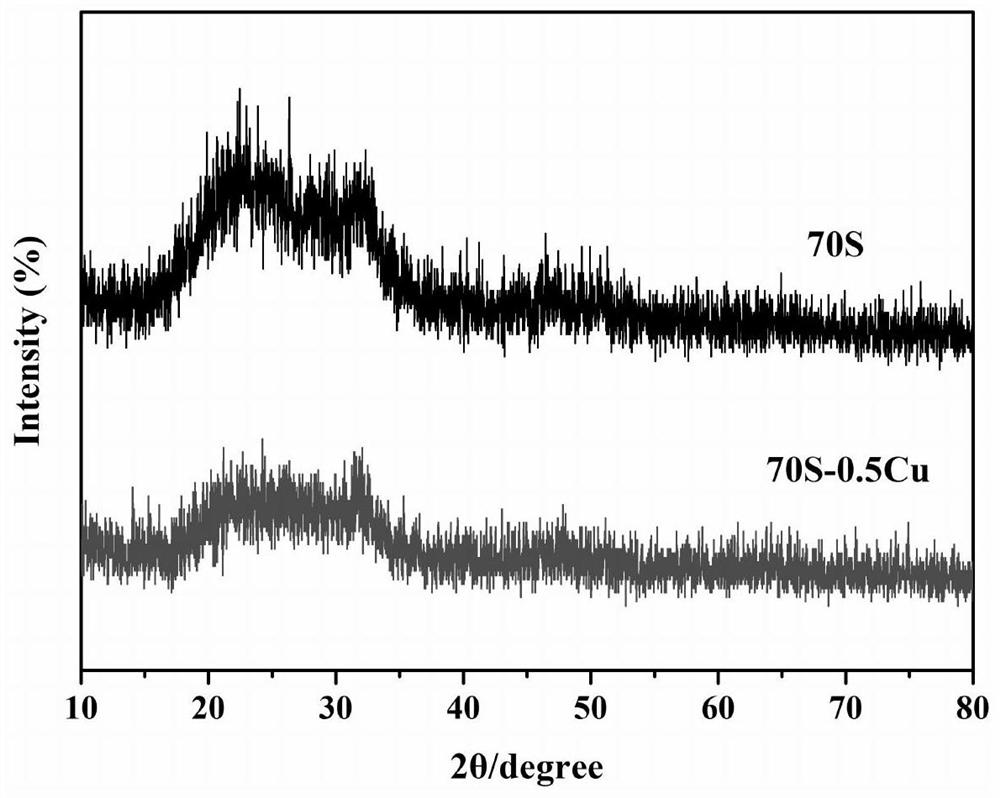

[0028] Preparation of 70S bioactive glass dressing: Take a closed container with a cover, add 20ml of ultrapure water, then add 5ml of 2M dilute nitric acid solution, absorb 33.5ml of tetraethyl orthosilicate (TEOS) and add it to the aqueous solution containing nitric acid, and stir the mixture at room temperature Hydrolysis reaction 30min. Then at intervals of 30min, 13.16g of calcium nitrate (Ca(NO 3 ) 2 ·4H 2 (0), 2.9ml triethyl phosphate (TEP), then stirred for 5h until a uniform, transparent sol was formed. The sealed sol was placed at 60°C for 48h, and then dried at 120°C for 24h. The dried gel was ground and then calcined in a muffle furnace at 700°C for 3h. Finally, the calcined sample was ground and passed through a 200-mesh sieve to obtain a powder sample.

Embodiment 2

[0030] Preparation of 0.5% Cu bioactive glass dressing: Take a closed container with a cover, add 20ml of ultrapure water, then add 5ml of 2M dilute nitric acid solution, draw 33.5ml of tetraethyl orthosilicate (TEOS) into the aqueous solution containing nitric acid, mix The hydrolysis reaction was stirred at room temperature for 30 min. Then at intervals of 30min, 12.9g of calcium nitrate (Ca(NO 3 ) 2 ·4H 2 O), 2.9ml triethyl phosphate (TEP) and 0.26g copper nitrate (Cu(NO 3 ) 2 ·3H 2 O), then stirred for 5h until a uniform, transparent sol was formed. The sealed sol was placed at 60°C for 48h, and then dried at 120°C for 24h. The dried gel was ground and then calcined in a muffle furnace at 700°C for 3h. Finally, the calcined sample was ground and passed through a 200-mesh sieve to obtain a powder sample.

Embodiment 3

[0032] Preparation of 1% Cu bioactive glass dressing: Take a closed container with a cover, add 20ml of ultrapure water, then add 5ml of 2M dilute nitric acid solution, draw 33.5ml of tetraethyl orthosilicate (TEOS) into the aqueous solution containing nitric acid, mix The hydrolysis reaction was stirred at room temperature for 30 min. Then at intervals of 30min, 12.65g of calcium nitrate (Ca(NO 3 ) 2 ·4H 2 O), 2.9ml triethyl phosphate (TEP) and 0.52g copper nitrate (Cu(NO 3 ) 2 ·3H 2 O), then stirred for 5h until a uniform, transparent sol was formed. The sealed sol was placed at 60°C for 48h, and then dried at 120°C for 24h. The dried gel was ground and then calcined in a muffle furnace at 700°C for 3h. Finally, the calcined sample was ground and passed through a 200-mesh sieve to obtain a powder sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com