Cutting device for steel plate machining

A technology for cutting devices and steel plates, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve problems affecting cutting effects, air pollution, and unfavorable health of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

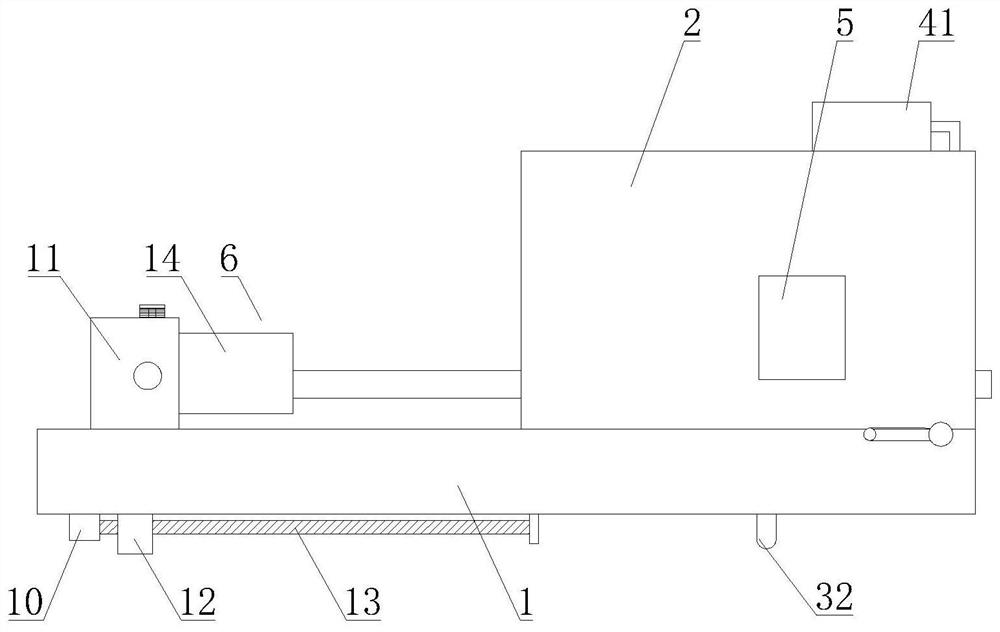

Method used

Image

Examples

Embodiment 2

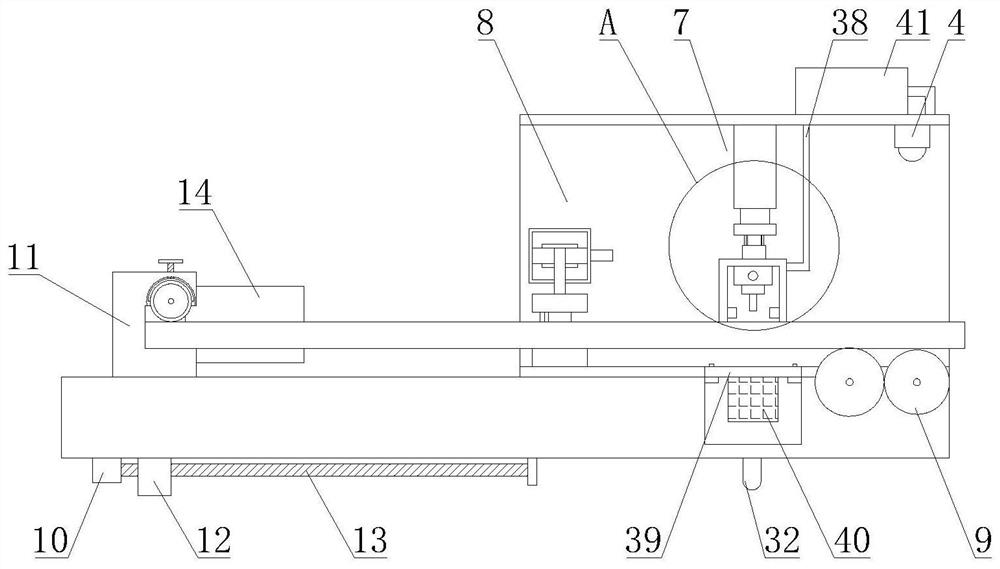

[0050] Such as Figure 8-10 As shown, a positioning assembly 8 is also included; the positioning assembly 8 is arranged between the feeding assembly 6 and the dustproof assembly 7, and includes a mounting frame 42, a fourth driving motor 43, a rotating shaft 44, a rotating belt 45, a positioning member 46 and a connecting member 47; the mounting frame 42 is arranged inside the cutting chamber 2, and spans above the steel plate; two sets of rotating shafts 44 transmitted by the fourth driving motor 43 are arranged, and the two groups of rotating shafts 44 are rotated and arranged at both ends of the mounting frame 42; Belt 45 is sleeved on two groups of rotating shafts 44, and rotates synchronously with it; Two groups of connectors 47 are arranged, and two groups of connectors 47 connect the upper stratum and the lower floor of rotating belt 45 respectively; 47 one-to-one correspondence connections.

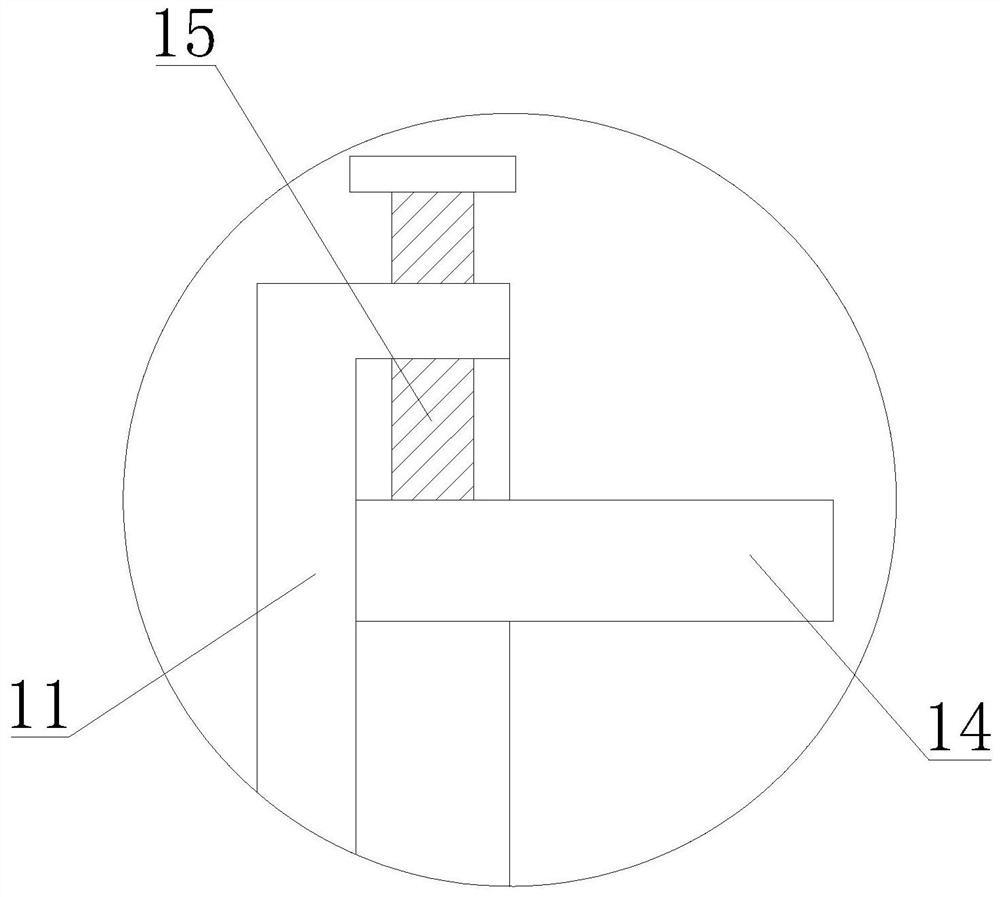

[0051] In an optional embodiment, the positioning member 46 includes an uppe...

Embodiment 3

[0055] The present invention proposes a kind of steel plate cutting method again, and the steps are as follows:

[0056] S1, place the steel plate on the console 1;

[0057] S2. Clamp one end of the steel plate in the first engaging groove of the feeding assembly 6, rotate the first threaded rod 15, and move the second engaging frame 14 towards the steel plate until both sides thereof are locked in the second engaging groove, At the same time, the fixing member 16 is operated, so that the fixing plate 18 blocks the anti-skid wheel 17;

[0058] S3, operate the positioning assembly 8, the rotating belt 45 rotates, drives the positioning member 46 to move towards the steel plate, lifts the steel plate, makes it placed on the lower positioning plate 49, and engages with the rotating roller 50;

[0059] S4, the feeding assembly 6 works, the first driving motor 10 drives the first lead screw 13 to rotate, the first engaging frame 11 moves toward the cutting chamber 2 at a constant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com