Method for separating and recovering iron, rare earth and fluorine from rare-earth-contained tailings after beneficiating iron

A technology for separation, recovery and magnetic separation of tailings, applied in solid separation, improvement of process efficiency, calcium/strontium/barium fluoride, etc., can solve the problem of inability to efficiently separate and recover iron, small difference in magnetic susceptibility, and low recovery rate of tailings and other problems, to achieve good kinetic conditions, low production costs, and improved reduction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

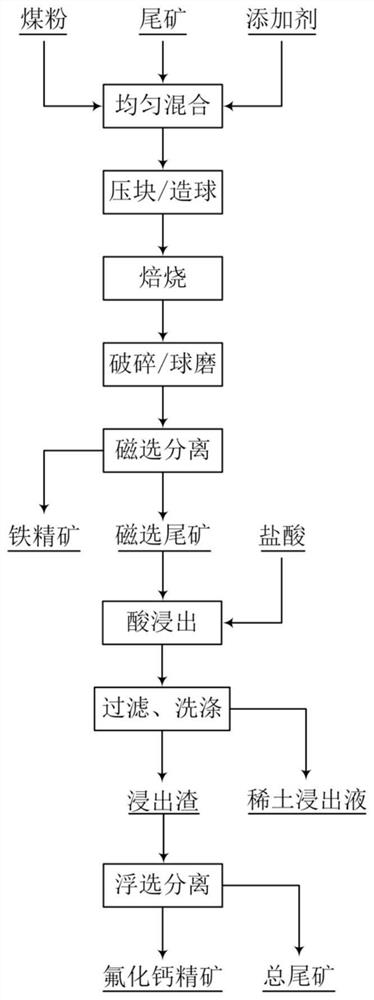

[0053]A method of separating recycled iron, rare earth and fluorine from the selection of rare mines with rare earths in Baiyun, and, flow schematicfigure 1 As shown, the specific steps are as follows:

[0054](1) Put Baiyun, a rare earth-free ore, (with 12.4% by mass fraction, its rare earth (with REO) content is 8.7%, the iron element content is 14.5%, its dioxide The silicon content is 11.5%, its calcium oxide content is 11.9%, its calcium fluoride content is 25.6%;) additive (calcium oxide powder) and pulverized coal (fixed carbon content 80%) according to 100: 10: 6.7 The proportion is uniformly mixed to give a mixture.

[0055](2) Press the material after mixing the material into a block or a ball, and the treated material is treated with a block or spherical material, the calcination temperature is 1150 ° C, the calcination temperature is 120 minutes, and the bake is ended. After water, it is cooled to obtain a baking mine.

[0056](3) Treatment of the baked mine after cooling in step...

Embodiment 2

[0064](1) Popularizing the ribbing mine of Baiyun, rare earth (which is 12.5% by mass fraction, its rare earth (with REO) content is 7.1%, the iron element content is 20.4%, its silica The content is 12%, its calcium oxide content is 7.5%, its calcium fluoride content is 25.6%), additives (calcium carbonate powder) and pulverized coal (fixed carbon content of 80%) are uniform according to 100: 20: 10 Mixed to give a mixture.

[0065](2) Press the material after mixing the material after step (1), and the treated material is treated with a block-shaped or spherical material, the calcination temperature is 1200 ° C, the calcination temperature is 60 minutes, and the bake is completed. After water, it is cooled to obtain a baking mine.

[0066](3) Cooling the calcined ore after cooling in step (2), the final material particles are less than 75 microns to 80% or more.

[0067](4) The ball milling product obtained by step (3) is magnetically selected separately, magnetic selection is performed ...

Embodiment 3

[0074](1) Putting Baiyun, rare earth-tail mite (whose fluorine element content is 10.2% (mass fraction), and its rare earth (with REO) content is 8.7% (mass fraction), and its iron element content is 14.5%. Quality fraction), its silica content is 15% (mass fraction), its calcium oxide content is 11.9% (mass fraction), its fluoride content is 20.9% (mass fraction)), additive (Dolomite powder) and Coal (fixed carbon content is around 60%) is uniformly mixed according to 100: 21: 9.3 mass proportion to obtain a mixture.

[0075](2) Press the material after mixing the material after step (1), and the treated material is treated with a block or spherical material, the calcination temperature is 1100 ° C, the calcination temperature is 100 minutes, and the bake is ended. After water, it is cooled to obtain a baking mine.

[0076](3) Cooling the calcined ore after cooling in step (2), the final material particles are less than 75 microns to 80% or more.

[0077](4) The ball milling product obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com