Nanoscale superfine fiber composite melt-blown cloth and preparation method thereof

A technology of ultra-fine fiber and melt-blown cloth, which is applied in the direction of fiber type, fiber treatment, biochemical fiber treatment, etc., and can solve the problems of poor mechanical properties of melt-blown cloth, inability to take it out quickly, and rapid cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

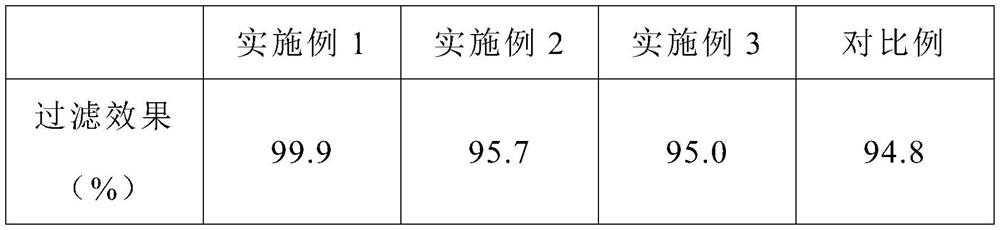

Examples

Embodiment 1

[0034] A nano-scale superfine fiber composite melt-blown cloth mainly includes, in parts by weight: 10 parts of polypropylene, 35 parts of modified polypropylene, and 8 parts of modified bacterial cellulose.

[0035] A preparation method of nanoscale superfine fiber composite melt-blown cloth, mainly comprising the following steps:

[0036] (1) Mix polypropylene and maleic anhydride at a mass ratio of 5:2, add dicumyl peroxide of 0.1 times the mass of polypropylene, and extrude it with a twin-screw extruder at a temperature of 200°C. Granules to obtain modified polypropylene;

[0037] (2) Mix the modified polypropylene obtained in step (1) with polypropylene in a mass ratio of 3:1, after hot-melt extrusion, filter, and spin to obtain pretreated nano-scale superfine fiber composite melt-blown cloth;

[0038] (3) Mix bacterial cellulose and sodium periodate solution with a mass fraction of 3% at a mass ratio of 1:8, oxidize it at a temperature of 50°C for 10 hours, and then fil...

Embodiment 2

[0046] A nano-scale superfine fiber composite melt-blown cloth, mainly comprising: 10 parts of polypropylene, 35 parts of modified polypropylene, and 8 parts of bacterial cellulose in parts by weight.

[0047] A preparation method of nanoscale superfine fiber composite melt-blown cloth, mainly comprising the following steps:

[0048] (1) Mix polypropylene and maleic anhydride at a mass ratio of 5:2, add dicumyl peroxide of 0.1 times the mass of polypropylene, and extrude it with a twin-screw extruder at a temperature of 200°C. Granules, modified polypropylene;

[0049] (2) Mix the modified polypropylene obtained in step (1) with polypropylene in a mass ratio of 3:1, after hot-melt extrusion, filter, and spin to obtain pretreated nano-scale superfine fiber composite melt-blown cloth;

[0050] (3) Mix bacterial cellulose and acetone at a mass ratio of 1:10, and add diisopropylamine 0.2 times the mass of bacterial cellulose, and 6 times the mass of bacterial cellulose. The melt...

Embodiment 3

[0053] A nano-scale superfine fiber composite melt-blown cloth mainly includes 45 parts of polypropylene and 8 parts of modified bacterial cellulose in parts by weight.

[0054] A preparation method of nanoscale superfine fiber composite melt-blown cloth, mainly comprising the following steps:

[0055] (1) After the polypropylene is hot-melt extruded, filtered and spun, the pretreated nano-scale superfine fiber composite melt-blown cloth is obtained;

[0056] (2) Mix bacterial cellulose and sodium periodate solution with a mass fraction of 3% at a mass ratio of 1:8, oxidize it at a temperature of 50°C for 10 hours, and then filter with suction to obtain oxidized bacterial cellulose, which is oxidized Bacterial cellulose and ethylene glycol solution with a mass fraction of 30% were mixed and reacted for 1 hour at a mass ratio of 1:10, then suction filtered and freeze-dried to obtain a bacterial cellulose mixture blank, and the bacterial cellulose mixture blank and collagen gel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com