Temperature-stable microwave dielectric ceramic as well as preparation method and application thereof

A microwave dielectric ceramic and temperature-stable technology, applied in the field of microwave dielectric ceramics, can solve the problems of inability to meet the high requirements of microwave dielectric ceramic materials and poor temperature stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

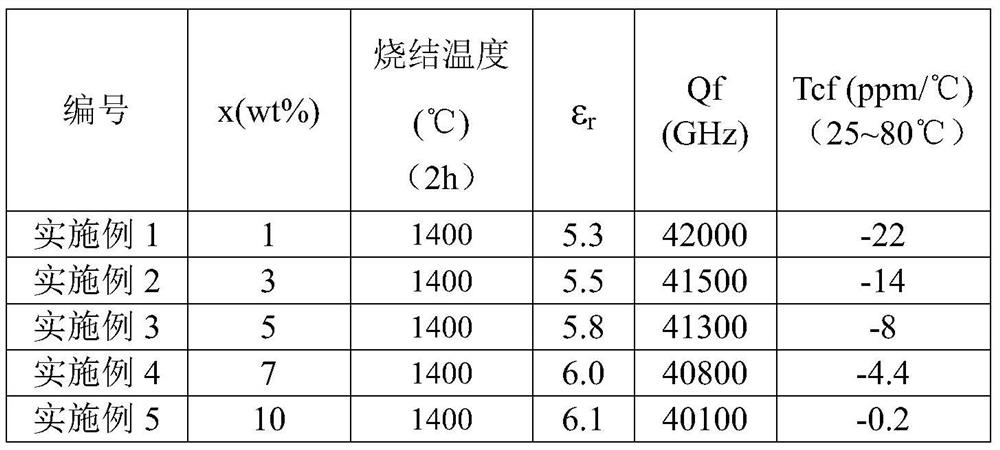

Examples

preparation example Construction

[0025] The present invention also provides a method for preparing a temperature-stable microwave dielectric ceramic, comprising the following steps:

[0026] (1) The main material for preparing microwave dielectric ceramics: according to the chemical structural formula Mg 2 al 4 Si 5 o 18 The molar ratio of each element in MgO, Al 2 o 3 , SiO 2 Carry out batching separately, mix above-mentioned batching sufficiently, carry out ball milling, after ball milling, dry and sieve, put into corundum crucible to roast then, obtain main ingredient;

[0027] (2) Preparation of auxiliary materials for microwave dielectric ceramics: according to the chemical structural formula Zr 0.6 sn 0.4 TiO 4 The molar ratio of each element in ZrO 2 , SnO 2 、TiO 2 Carry out batching separately, mix above-mentioned batching sufficiently, carry out ball milling, after ball milling, dry and sieve, put into corundum crucible to roast then, obtain auxiliary material;

[0028] (3) Preparation of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com