A grinding and polishing device for aluminum alloy metal parts

A technology for metal parts and aluminum alloys, which is applied in the field of grinding and polishing devices for aluminum alloy metal parts, can solve the problems of reducing the efficiency of aluminum alloy plate grinding and polishing, increasing the labor intensity of staff, and areas that cannot be polished and polished, so as to ensure adsorption Stability, reduced loading and unloading times, convenient placement and clamping effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

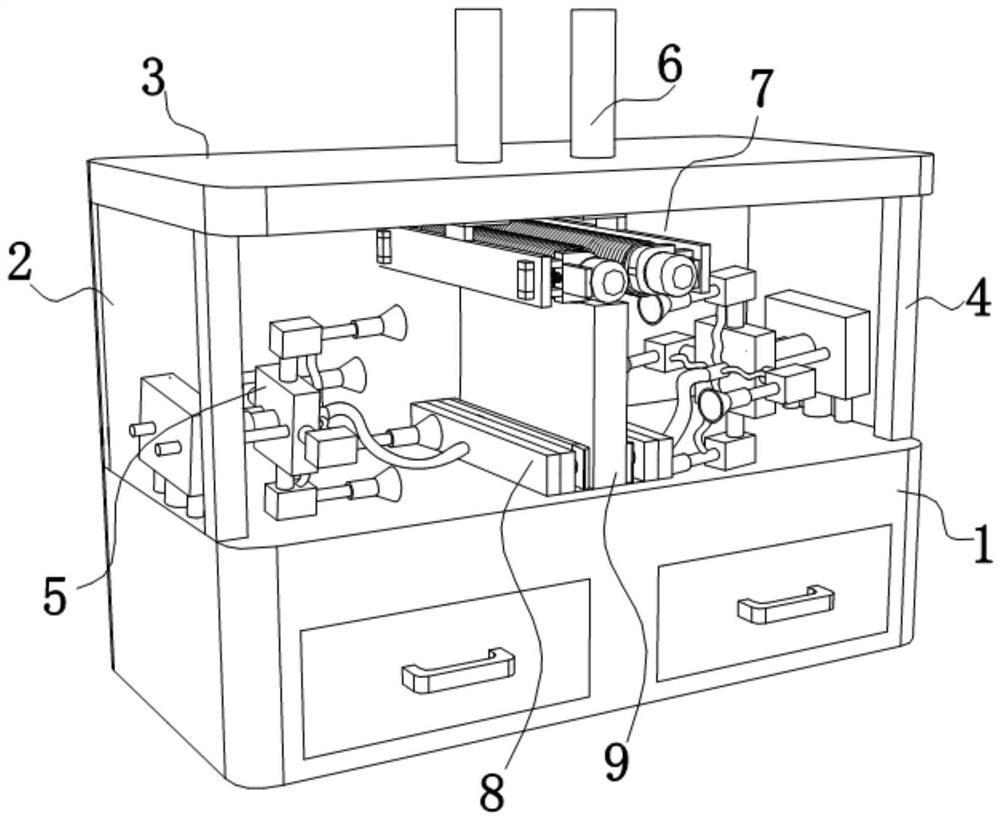

[0034] Such as Figure 1-Figure 8 As shown, a grinding and polishing device for aluminum alloy metal parts includes a grinding table 1 and an aluminum alloy plate 9, and the top of the grinding table 1 is provided with two sets of symmetrically distributed fixing components 5;

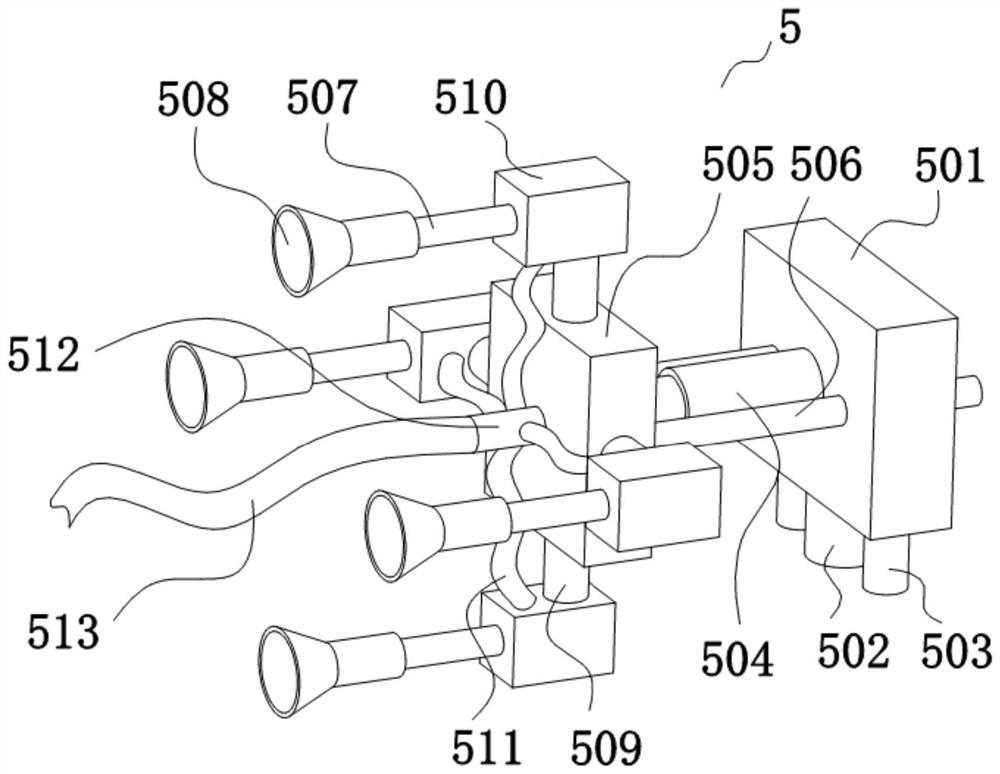

[0035] The fixing assembly 5 includes a first hydraulic rod 502. The installation end of the first hydraulic rod 502 is arranged on the top of the grinding table 1, and the output end of the first hydraulic rod 502 is provided with a fixed plate 501. The first hydraulic rod 502 mainly controls the movement of the fixed plate 501. Lifting, so as to facilitate the correspondence with the position of the aluminum alloy plate 9, to ensure the accuracy of follow-up work, the bottom of the fixed plate 501 is provided with two first limit rods 503, and the top of the grinding table 1 is provided with two sets of second limit grooves 17, The bottom end of the first limit rod 503 is located in the second limit ...

no. 2 example

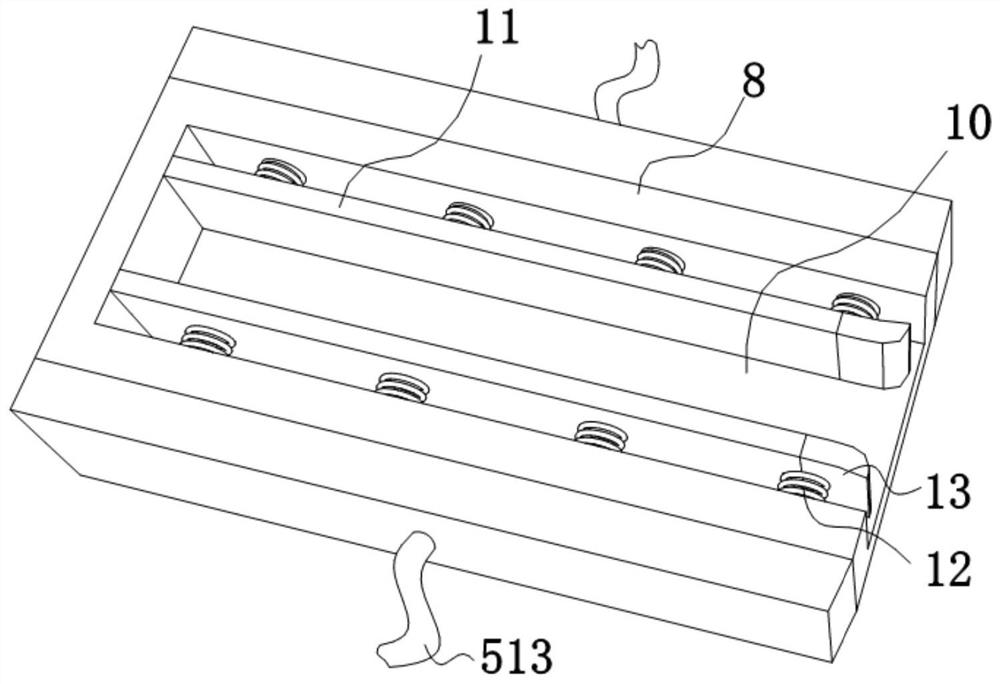

[0041] Based on the grinding and polishing device for aluminum alloy metal parts provided in the first embodiment, if there are small particles of impurities attached to the surface of the aluminum alloy plate 9 during actual use, when the aluminum alloy plate 9 is fixed by the adsorption force of the suction cup 508, it will Occurrence of unstable fixation phenomenon, so that the aluminum alloy plate 9 will fall during the grinding process and cause huge losses, and after the suction cup 508 absorbs the aluminum alloy plate 9, it is still necessary to manually open and clamp the magnetic plate 11. Release its clamping effect on the aluminum alloy plate 9. This operation is too cumbersome and greatly reduces the grinding rate. In order to solve this problem, the aluminum alloy plate 9 is pre-cleaned and easy to disassemble. The grinding and polishing device for aluminum alloy metal parts also includes: the end of the first air duct 507 away from the suction cup 508 passes throu...

no. 3 example

[0044] Based on the grinding and polishing device for aluminum alloy metal parts provided in the second embodiment, only the grinding roller 709 is used to grind the two sides of the aluminum alloy plate 9, and the grinding process is simply controlled by the first spring 708, so it cannot Accurately control the depth and degree of grinding. At the same time, a large amount of impurities and dust will inevitably be generated during the grinding process. If it is not treated, it will inevitably cause interference to the grinding process. In order to solve this problem, achieve precise control of the grinding depth , the grinding and polishing device for aluminum alloy metal parts also includes: the grinding assembly 7 includes an electromagnetic horizontal plate 701, and a current is passed through the electromagnetic horizontal plate 701, so that the electromagnetic horizontal plate 701 will generate a magnetic field, and the direction and size of the magnetic field can be Thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com