A kind of composite lithium metal negative electrode and its preparation method and application

A metal negative electrode and composite lithium technology, which is applied in electrode manufacturing, electrode rolling/calendering, battery electrodes, etc., can solve the problems of lack of preparation methods for composite lithium metal negative electrodes, achieve excellent cycle stability, inhibit the growth of dendrites, The effect of good affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

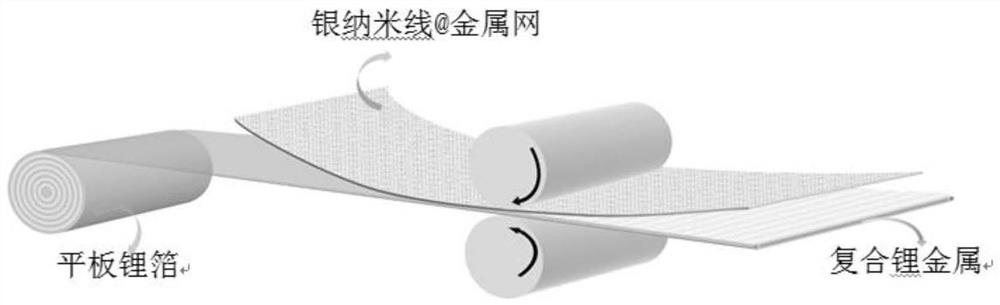

[0034] A composite lithium metal negative electrode, such as figure 1 As shown, it is prepared by the following method:

[0035] (1) The silver nanowire ink having a concentration of 0.5 mg / ml is prepared, and the diameter is 12mm. The copper network is 200 destination, then the copper net is immersed in 200 μL of silver nanowire ink, soaked for 5 seconds, take it out Drying treatment in an oven at 40 ° C, which is made of copper networks loaded with silver nanowires;

[0036] (2) In the argon atmosphere conditions, the copper network loaded with silver nanowires is paved on the metal lithium foil, and then the two are placed in the roller press to carry out the roller pressure, remove the copper web, to obtain recombination lithium Metal negative electrode.

Embodiment 2

[0038]The present embodiment is mainly different from the first embodiment in that the concentration of the silver nanowire ink and the objective number of the copper network are different, as described below.

[0039] A composite lithium metal negative electrode, prepared by the following method:

[0040] (1) First formulate silver nanowire ink having a concentration of 2 mg / ml, preparing a diameter of 12mm and a copper network of 300 destination, then impiltrate the stainless steel net into 200 μL of silver nanowire ink, soak 5 seconds, take it out to 50 Drying treatment in ° C oven, resulting in a stainless steel net with silver nanowire;

[0041] (2) In the argon atmosphere conditions, the stainless steel nets loaded with silver nanowires are paved on the metal lithium foil, and then the two are placed in the roller press for rolling, and the stainless steel net can be obtained. Metal negative electrode.

Embodiment 3

[0043] The present embodiment is mainly different from the first embodiment in that the concentration of the silver nanowire ink and the objective number of the copper network are different, as described below.

[0044] A composite lithium metal negative electrode, prepared by the following method:

[0045] (1) The silver nanowire ink having a concentration of 3.5 mg / ml is prepared, and the diameter is 12mm and a copper net of 400 destination, then the copper net is immersed in 200 μL of silver nanowire ink, soak for 5 seconds, take it out Drying treatment in an oven at 60 ° C, and the copper network having a silver nanowire is made;

[0046] (2) In the argon atmosphere conditions, the stainless steel net of the silver nanowire is paved on the metal lithium foil, and then the two are placed in the roller press for rolling, and the copper web can be obtained. Metal negative electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com