Low-warpage ASA composite material for 3D printing and preparation method thereof

A composite material, 3D printing technology, applied in the field of 3D printing materials, can solve the problems of easy aging and yellowing mechanical properties, temperature difference resistance, warping deformation and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

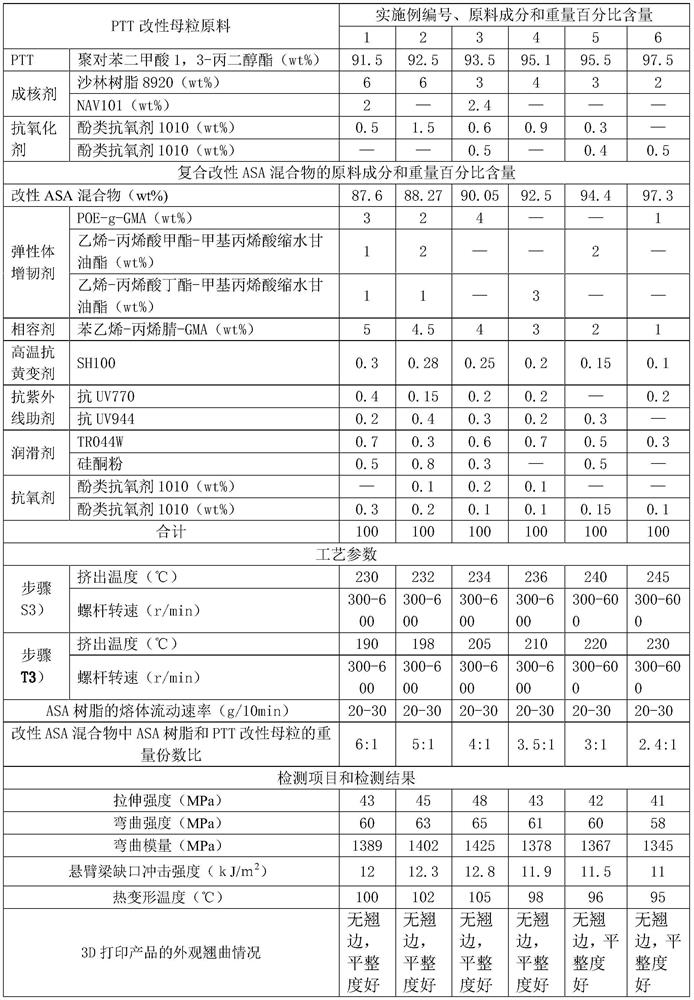

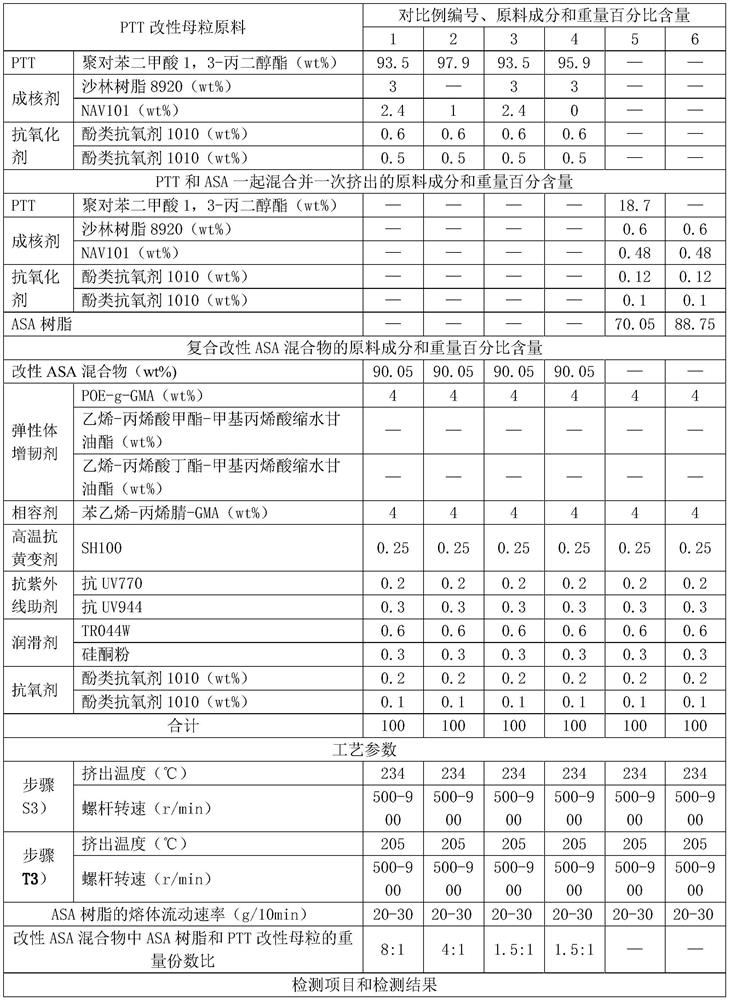

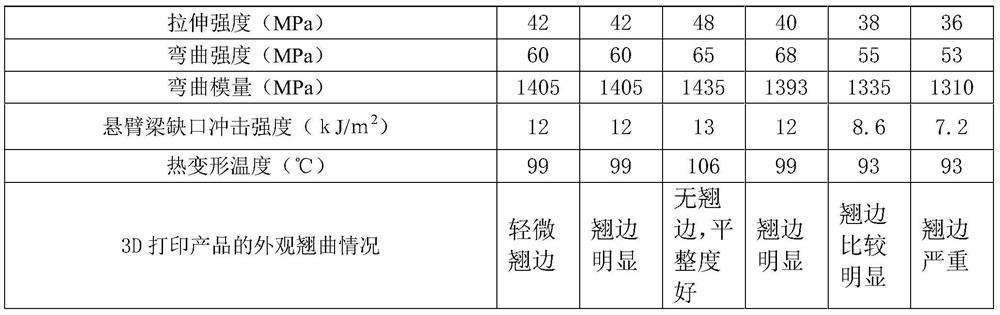

Examples

preparation example Construction

[0081] The preparation step of described ASA composite material comprises:

[0082] T1) Weigh the ASA resin and the PTT modified masterbatch respectively, mix and stir evenly and dry until the contained moisture is lower than 0.05%, to prepare the modified ASA mixture;

[0083] T2) In the modified ASA mixture, add elastomer toughening agent, compatibilizer, high temperature anti-yellowing agent, anti-ultraviolet auxiliary agent, lubricant and antioxidant, mix and stir evenly, and prepare a composite ASA mixture;

[0084] T3) The composite ASA mixture is put into a twin-screw extruder, heated to melt and extruded, and the ASA composite material is obtained.

[0085] The melt flow rate of described ASA resin is 20-30g / 10min;

[0086] The elastomer toughening agent is at least one of POE-g-GMA, ethylene-methyl acrylate-glycidyl methacrylate and ethylene-butyl acrylate-glycidyl methacrylate;

[0087] The compatibilizer is styrene-acrylonitrile-GMA.

[0088] The high-temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com