Fiber-reinforced polypropylene composition and foamed polypropylene composite material and preparation method thereof

A polypropylene composition and fiber reinforcement technology, applied in the field of modified polypropylene, can solve the problems of complex preparation method and high cost, and achieve the effects of excellent compressive performance, high compressive stress and high compressive rebound rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

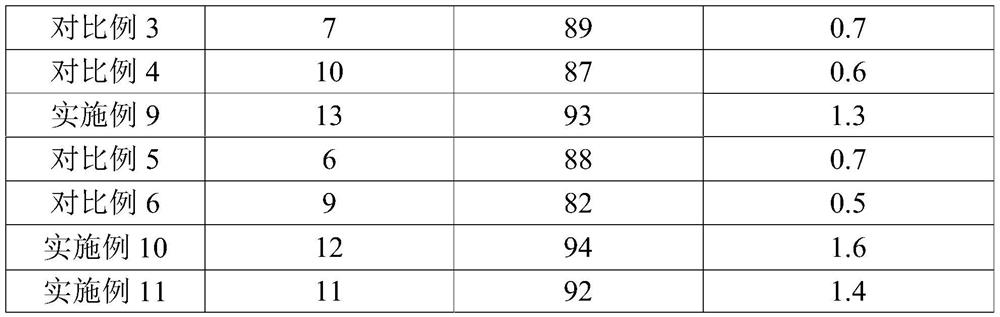

Examples

preparation example Construction

[0020] In the present invention, the preparation method of the polypropylene modifier comprises: contacting the polar monomer-grafted polypropylene in combination I or combination II with component A for reaction extrusion granulation, and then drying. Combination I or combination II consists of polar monomer grafted polypropylene and component A respectively.

[0021] In the combination I, the polar monomer in the polar monomer-grafted polypropylene is selected from maleic anhydride, acrylic acid, acrylate, methacrylic acid, methacrylate, vinyl tertiary carbonate, glycidyl methacrylate At least one of ester, dimethylamino methacrylate, epoxy acrylate, isocyanurate and acrylamide; said component A is selected from at least one of polyisocyanate and polyethylene oxide One; and the selected polar monomer is used in conjunction with the selected component A, which needs to undergo a chemical reaction during the reactive extrusion process.

[0022] Preferably, the acrylate is at ...

Embodiment approach

[0026] According to a specific embodiment, the first compound is 4,4'-diaminodiphenyl ether, phenoxyaniline, 3,4'-diaminodiphenyl ether and 3,3',4,4' - one or more tetraaminodiphenyl ethers, preferably phenoxyaniline and / or 3,3',4,4'-tetraaminodiphenyl ether.

[0027] In the present invention, the second compound may be one of alkylene diamine, alkylene diamine, alkylene triamine, alkylene tetramine, alkylene pentamine and aryl diamine or Various, such as C2-12 alkylene diamine, C2-12 alkylene diamine, C2-C12 alkylene triamine, C2-C12 alkylene tetramine, C2-C12 alkylene One or more of base pentamine and C6-C18 aryl diamine.

[0028] According to a specific embodiment, the second compound is tetraethylenepentamine, triethylenediamine, diethylenetriamine, triethylenetetramine, p-phenylenediamine, m-phenylenediamine, One or more of 1,8-octanediamine, 1,9-diaminononane, 1,10-diaminodecane and 1,12-diaminododecane.

[0029] In the present invention, in Combination I and Combinat...

Embodiment 1

[0058] (1) Preparation of polypropylene modifier

[0059] Weigh 99 parts of acrylic acid-grafted polypropylene (graft rate: 1.2%, MI 52 g / 10min, the same below), and 1 part of 2,4-xylene diisocyanate and mix well. Put the fully mixed raw materials into the HAAKE twin-screw extruder, the extrusion temperature is set at 190°C, the extruder speed is 50r / min, and the feeding speed is 3Hz. Extrude and granulate, and dry the obtained product at 90°C for 60 minutes to obtain a polypropylene modifier. The polypropylene modifier sample preparation is carried out infrared analysis, in the infrared spectrogram, 3350cm -1 and 1540cm -1 The carbamate characteristic peak generated after the reaction of -NCO and -OH appears, and -OH is at 3400cm -1 -3500cm -1 The characteristic peak at 1727cm -1 The characteristic peak at is significantly enhanced, indicating that acrylic acid reacts with isocyanate, and the prepared product is the target product.

[0060] (2) Preparation of foamed pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive stress | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com